In recent times, a variety of composite materials have been used in the manufacture of automobiles, and silicone as an emerging resource with a wide range of applications in recent years, also plays an important role in the automotive industry, such as automotive sealants which can adhere to glass and metal. So why choose silicone for automotive?

Silicone rubber is resistant to extreme temperatures, with a temperature range of -40-230 ℃; it has good softness, comfortable to the touch, not deformed; strong electrical insulation properties, with good resistance properties; a long service life and stable nature because of the chemical properties of silicones. So silicone rubber is widely used in the automotive industry.

The following four aspects of the application of silicone rubber in the automotive industry:

- What are the properties of silicone?

- What are the advantages of low surface energy of silicone?

- How to apply silicone to automotive?

- How to make automobile performance better?

1. What are the properties of silicone?

(1) High-temperature resistance.

Automotive silicone materials have excellent high-temperature resistance and can maintain stability in harsh automotive environments. They are suitable for engines, exhaust systems, and braking systems that need to withstand high temperatures.

(2) Weathering:

Automotive silicone materials have excellent weathering resistance and can resist tight ultraviolet rays, ozone, weathering, and other factors, to extend the service life of automotive parts. Such as silicone sealant, can be resistant to moisture.

(3) Vibration resistance:

Automotive silicone materials have good anti-vibration properties, can absorb and buffer vibration, reduce noise and vibration in the process of automobile driving, and improve driving comfort.

![]()

2. What are the advantages of low surface energy of silicone?

(1) Easy mold release.

Automotive silicone materials have low surface energy, easy to release the mold, suitable for precision molding of automotive parts, and improve production efficiency.

(2) Stain Resistance:

Automotive silicone materials have low surface energy, good dirt resistance, and water resistance, suitable for automotive interior parts, exterior parts, and other parts that often need to be cleaned.

(3) Scratch resistance:

Automotive silicone materials have low surface energy, which can reduce wear and scratches, and are suitable for automobile body paint, dashboards, and other surfaces that need protection.

![]()

3. How to apply silicone to automotive?

3.1 In the automobile engine system

(1) Silicone rubber is widely used in the engine cylinder head gasket, crankshaft oil seal, intake manifold gaskets, and other parts, with good high-temperature resistance, oil resistance, corrosion resistance, and anti-aging properties, silicone sealant can effectively prevent engine oil leakage, air leakage, prolong the engine life to reduce emissions.

(2) Silicone rubber is also widely used in engine cooling systems, such as coolant lines, water pump seals, etc., with excellent heat resistance, cold resistance, and aging resistance, which can ensure that the cooling system works properly to prevent engine overheating.

(3) Silicone rubber also plays an important role in automobile ignition systems, such as spark plug sleeves, ignition coil insulating sleeves, etc., with good resistance to high temperature, arc resistance, and aging resistance, to ensure the normal operation of the ignition system, to prevent leakage, short-circuit and other faults.

![]()

![]()

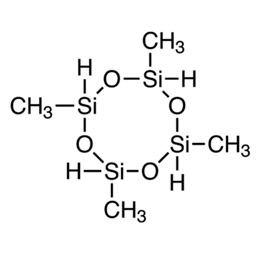

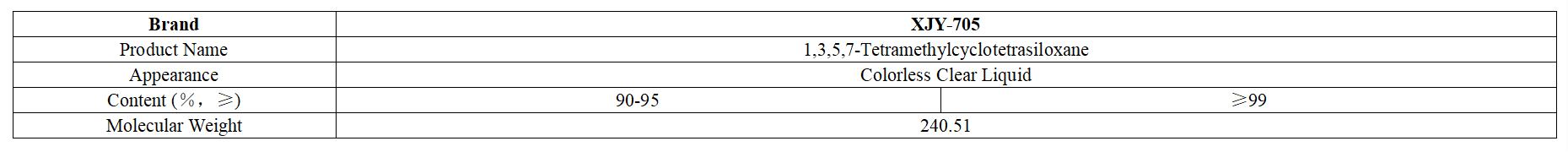

XJY-705 1,3,5,7-Tetramethylcyclotetrasiloxane (D4H) It is a reactive siloxane with a Si-H bond, which can be used to synthesize room-temperature vulcanized silicone rubber(rtv silicone) with additional changes of unsaturated olefins.

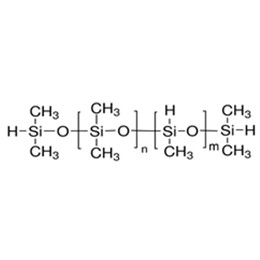

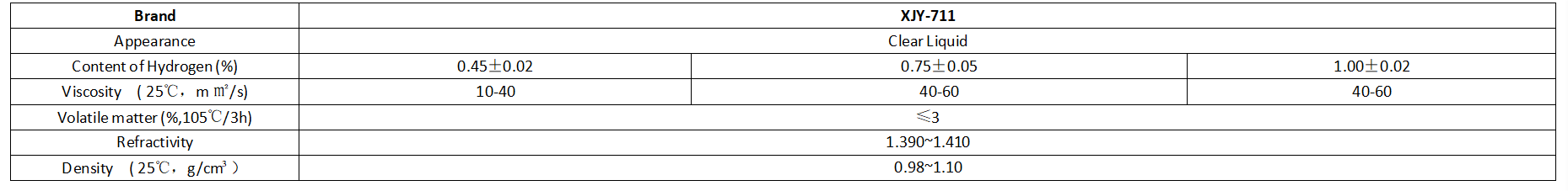

XJY-711 Hydride Terminated Methylhydrosiloxane/Dimethylsiloxane Copolymer is a colorless and transparent liquid, which can be applied as crosslinking additives for silicone rubber.

3.2 In the automobile transmission system

(1) Silicone rubber is widely used in automobile transmission oil seals, differential oil seals, drive shaft universal joint seals, tube seals, and other components, with has good wear resistance, oil resistance, and high-temperature resistance, and can effectively prevent oil leakage, air leakage, prolong the life of the transmission system.

(2)Silicone rubber in the automobile clutch friction plate also plays an important role, it has good wear resistance, high-temperature resistance, and oil resistance, and can ensure that the clutch is normal work, to prevent slipping, shaking, and other failures.

(3) Automotive silicone rubber is also widely used in automotive tires, such as tire sidewalls, tread patterns, etc., with excellent wear resistance, aging resistance, and weather resistance, can extend the service life of the tire, and improve the safety of automobile driving.

![]()

![]()

3.3 In the automotive interior systems

(1) Silicone rubber is widely used in automotive instrument panels, center console, door trim, seats, and other parts, with good tactile wear resistance, heat resistance, cold resistance, and aging resistance, which can enhance the grade and texture of automotive interiors.

(2) Silicone rubber also plays an important role in automotive seals, sound insulation, and other components, with good weathering, aging resistance, and corrosion resistance, can effectively prevent wind noise, rain, dust, etc. in the car, and improve the comfort of the car.

(3) Silicone rubber also widely used in automotive airbags, such as airbag covers, airbag inflators, etc., with good resistance to high temperature and corrosion, and aging resistance, can ensure that the airbag at the critical moments of normal work, to protect the safety of drivers and passengers.

Silicone can also be used in automotive seat cushion leather:

Sileather automotive leather offers the most durable and luxurious animal-free vegan leather on the market, a perfect combination of nature and technology. The raw material used in Sileather is natural quartz ore that has been organically processed to form high-performance silicone resins, a source that greatly reduces dependence on fossil energy and defines the inherent excellence of Sileather. Sileather leather can be used in a wide range of applications for seating and upholstery.

![]()

3.4 In automotive electronic systems

(1) Silicone rubber is widely used in automotive electronic component encapsulation, wire and cable insulation, connector sealing, etc. It has good heat, cold, corrosion, and aging resistance, which ensures the normal operation of electronic components and prevents short-circuiting, leakage, and other failures.

(2) Silicone rubber also plays an important role, in automotive sensors, actuators, and other components with good heat resistance, cold resistance, corrosion resistance, and aging resistance, can ensure that the sensors, and actuators in harsh environments, normal work, improve the reliability and safety of the car.

(3) Silicone rubber is also widely used in automotive displays, touch screens, and other components, with good light transmission, abrasion resistance, and weather resistance, can improve the service life of the display, and touch screen, and enhance the user experience.

![]()

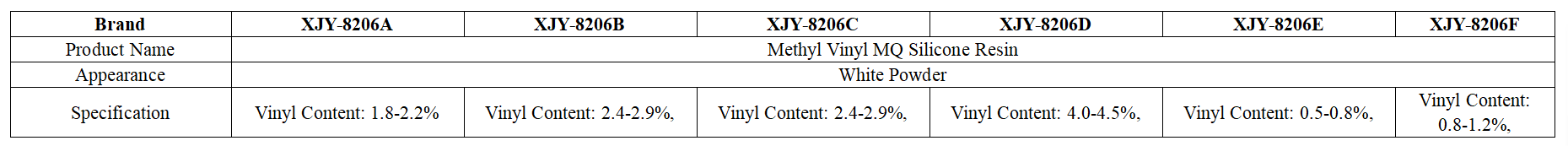

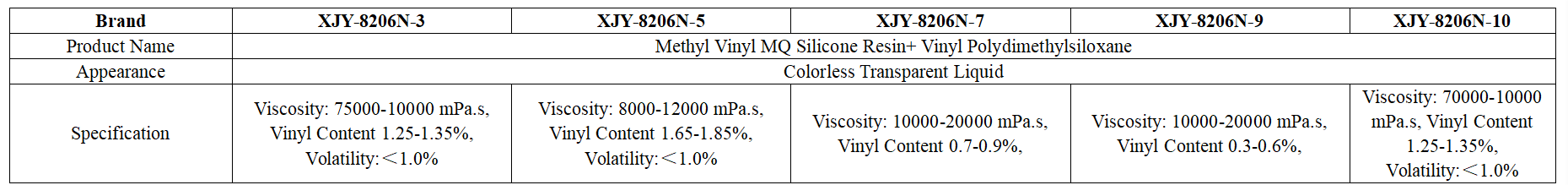

XJY-8206 Powder Series Methyl Vinyl MQ Silicone Resin can be used to make highly transparent and high-hardness VMQ silicone rubber, rtv silicone.

XJY-8206N Solution Series Methyl Vinyl MQ Silicone Resin+Vinylpolydimethylsiloxane can be applied can be used for highly transparent, high tear-resistant silicone rubber, rtv silicone.

3.4 In the automobile cable

Hybrid and pure electric vehicles relative to traditional fuel cars increase a lot of high-voltage accessories, such as power batteries, high-voltage distribution boxes, drive motors, motor controllers, etc., which also puts forward new requirements for automotive cables. As these cables are arranged in the front cabin engine and chassis area of high temperature, space is narrow, the need for cable soft, small turning radius, high and low-temperature performance; secondly, the road conditions are complex, the cable abrasion resistance must be good and high mechanical strength; in addition to the speed of the car is high at times low, especially fully loaded climbing and other harsh conditions, instantaneous high-current requirements of the cable line has a short-time overload capacity.

The current world of automotive power cable insulation materials are cross-linked polyolefin and thermoplastic elastomers. Cross-linked polyolefin materials are heat-resistant up to 150 ℃, but the material cable is relatively hard, in the narrow space of the car body installation is inconvenient, and the need for irradiation cross-linking, process complexity, is not suitable for large cross-section cable. Thermoplastic elastomer material is heat-resistant not more than 125 ℃, used for power cable temperature rating is low, and thermoplastic elastomer material cable long-term use will have the risk of cracking.

3.4.1 What are the advantages of silicone rubber in automotive high-voltage cable insulation and jacketing?

(1) Wider temperature range of -60~225°C

(2) Excellent tear resistance, flexibility, cable bending radius is small

(3) Good elasticity, more suitable for connection sealing

(4) Stable performance at high temperatures to give the cable a higher flow-carrying capacity

(5) Environmentally friendly products, to improve the car environment

3.5 In the automotive wiring harness sealing

Hybrid and pure electric vehicles need to be assembled with more wiring harnesses and sensors, wiring harness seals play a crucial role in facilitating the installation and sealing of wiring harnesses. Wiring harness seals mainly include single-wire seals and multi-cavity seals.

![]()

3.5.1 What are the advantages of using silicone rubber?

(1) Stable performance at high temperatures gives the cable a higher current-carrying capacity

(2) Self-lubricating surface, easy to insert terminals

(3) Mechanical strength to ensure that the terminal insertion process does not cause damage

(4) Ensure long-term sealing effect

(5) Good heat resistance

(6) Good oil resistance

(7) Easy molding and processing, stable quality control to improve the dimensional stability of finished products

4. How to make automobile performance better?

Silicone rubber is widely used in window seals, automotive headlights, and other parts of vibration and noise reduction, anti-fatigue and sheath design, intelligent lights, and other humanized designs to meet the comfort and safety of consumers driving. How to improve the competitiveness of your job and buy the goods in the online shop?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone rubber for the automotive field and support the provision of diversified customized solutions.