As silicone is more and more accepted by people, food-grade liquid silicone rubber raw materials can replace conventional materials has become a future trend in the development and design of household goods, liquid silicone rubber applications are also more and more, gradually derived from the maternal and baby industry. Why choose liquid silicone rubber for mother and baby field?

Liquid silicone rubber is a highly active adsorbent material, an amorphous material, liquid silicone rubber is an environmentally friendly material, the products used in mother and baby products are food-grade certified raw materials products. Liquid silicone rubber material has good curing and material shrinkage, and chemical resistance, is insoluble in water and any solvent, and is non-toxic, tasteless, chemically stable, in addition to strong alkali, hydrofluoric acid does not react with any substance. Its safety is widely used not only in medical devices but also in the maternal and baby industry.

This will discuss the following seven aspects of liquid silicone rubber in maternal and baby products:

- What is liquid silicone rubber?

- What are the features of liquid silicone molding?

- What are the advantages of liquid silicone rubber?

- What is the difference between liquid silicone and solid silicone?

- Why is liquid silicone rubber better than solid silicone?

- How to apply liquid silicone in the maternal and child industry?

- How to make baby products perform better?

1. What is liquid silicone rubber?

Liquid silicone rubber is a non-toxic, heat-resistant, highly resilient flexible thermosetting material. LSR is a double liquid rapid vulcanization material with a platinum catalyst, which can be used for repetitive mechanical production by liquid injection molding process. Its products exhibit good thermal stability, cold resistance, and excellent electrical insulation properties, and do not produce toxic substances when burned. Therefore, it has become an irreplaceable material in the production design of health products, automobiles, baby products, medical products, diving products, kitchen utensils, and seals.

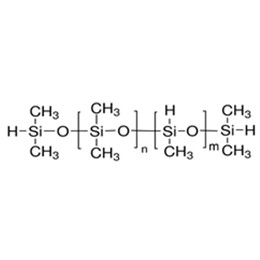

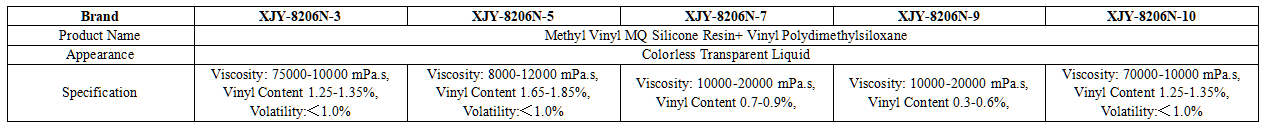

XJY-8205 Methyl MQ Silicone Resin

It is the product of co-hydrolysis of tetraalkoxysilane (Q unit) and trimethylalkoxysilane (M unit), which can be used as reinforcing material to prepare condensed liquid silicone rubber (LSR).

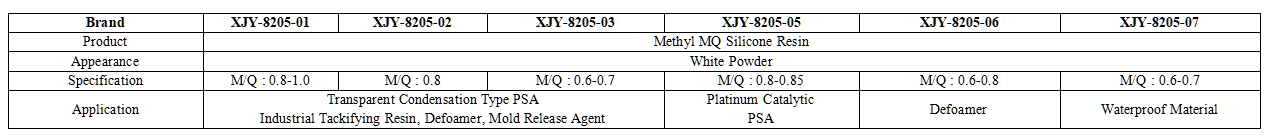

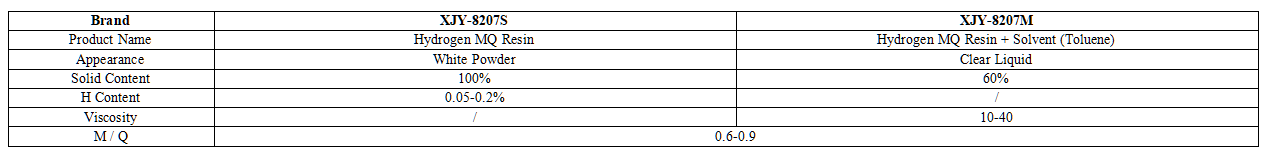

XJY-8207S/M Hydrogen MQ Resin

It can be used as a reinforcing filler for two-component addition adhesives such as RTV adhesive, HTV adhesive, and liquid silicone rubber (LSR).

XJY-8206N Methyl Vinyl MQ Silicone Resin/Vinyl Polydimethylsiloxane

It is a colorless and transparent liquid resin consisting of Vinyl MQ Organosilicone Resin and Vinyl Silicone Oil, which can be used for LSR, and also for other two-component additive adhesives.

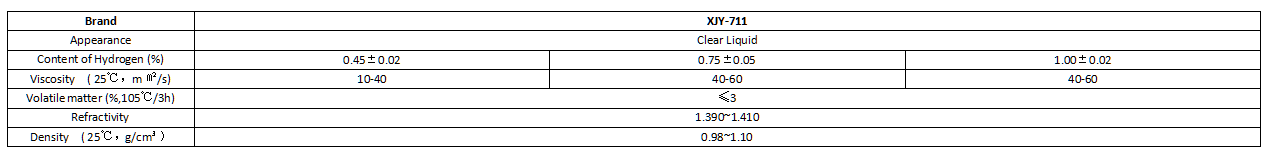

XJY-711 Hydride-Terminated Methylhydrosiloxane/Dimethylsiloxane Copolymer

It can be used as a special crosslinking agent for liquid silicone rubber LSR.

2. What are the features of liquid silicone molding?

Liquid injection molding is different from the characteristics of ordinary molded products:

(1) Liquid silicone rubber is a thermosetting material.

(2) Rheological behavior: low viscosity, fast curing, shear thinning, high coefficient of thermal expansion.

(3) Good fluidity, clamping force, and injection pressure are not high, but the injection accuracy is high;

(4) Exhaust design is relatively difficult, some products need to design the sealing vacuum structure, and mold precision requirements are high.

(5) The cylinder and casting system needs to design a cooling structure, and the mold needs to design a heating system.

Liquid silicone rubber is relative to the solid high-temperature vulcanization of silicone rubber, which is liquid rubber, with good fluidity, fast vulcanization, more security and environmentally friendly, and can fully meet the requirements of food grade. Liquid silicone rubber can be used for trademarks, products, pacifiers, medical supplies, coating, impregnation and infusion, and other purposes. The application of liquid silicone rubber in the maternal and child industry is very wide, relative to other industries, and its requirements are also the most stringent.

![]()

![]()

3. What are the advantages of liquid silicone rubber?

(1) Excellent transparency, and tear strength.

(2) High resilience

(3) Anti-yellowing;

(4) Thermal stability

(5) Good water resistance and air permeability;

(6) Heat aging resistance, weather resistance;

(7) Moderate viscosity, easy to operate, high product transparency.

![]()

4. What is the difference between liquid silicone and solid silicone?

(1) Appearance

A. Liquid silicone: uncured liquid silicone rubber, with fluidity.

B. Solid silicone: solid, no mobility.

(2) Application Scene

A. Liquid silicone: industrial supplies, household goods, medical industry food supplies, etc., can be in direct contact with the human body and food.

B. Solid silicone: generally used in intelligent hardware, 3C digital, and non-mobile phone fields.

(3) Environmental safety

A.Liquid silicone: platinum vulcanization, non-toxic and tasteless, belongs to the safety of food-grade materials.

B.Solid Silicone: Peroxide vulcanized, with a vulcanizing agent or masking the odor of vulcanizing agent, belongs to environmental protection material.

(4) Production method

A. Liquid Silicone: LSR injection molding process through injection molding machine is fully automated; short production cycle; materials without the need for front-end processing, more efficient, more labor-saving; can be used for two-color injection.

B. Solid silicone: need to batch, refining, cutting, manual feeding, and other processes, relatively low efficiency.

![]()

5. Why is liquid silicone rubber better than solid silicone?

When compared with solid silicone, the advantages of liquid silicone rubber parts are very significant.

(1) Safety

Liquid silicone rubber LSR can pass the food grade certification, baby pacifiers, sex toys, silicone dolls, etc. are made of liquid silicone rubber, non-toxic and non-stimulating to the human body.

(2) Easy to operate

Liquid silicone rubber LSR is very easy to operate, like manufacturing products or molds, and can be operated directly, without large-scale machines. And more effects can be used for different purposes.

(3) High precision

When used to manufacture products, the precision of liquid silicone rubber is higher than solid silicone, because liquid silicone rubber is liquid before curing, fine texture can also flow into the imitation.

6. How to apply liquid silicone in the maternal and child industry?

Liquid silicone rubber parts are a new material used in pacifiers, bottles, cups, toothbrushes, and even spoons and other products, with the frequent appearance of mother and baby products in its application, we began to gradually pay attention to it.

There are a lot of various baby products on the market, and when buying them, the eye-catching advertising slogans make people even more hesitant. No matter what you buy, baby breastfeeding or milk powder, the bottle is essential, the ingredients are the key to whether the product is suitable for children. Liquid silicone is used in bottles because of its non-toxic and non-irritating excellent performance safety is very high.

![]()

6.1 Liquid silicone nipples

The surface of baby pacifiers made of liquid silicone is smooth, extremely easy to clean, can be sterilized at high temperatures without damage, and is durable yet flexible. Especially suitable for babies to grow to 6 months after the use of this time the baby to start teething because the rubber pacifier is too soft, has no bite texture, and is easy to bite through, if not careful, the baby will also bite their own. For the baby's health and development, when the baby is full six months, be sure to use liquid silicone made of baby liquid silicone pediatric pacifier.

The pacifier is the part that actually touches the baby's mouth, so the material requirement is higher than that of a bottle. Pacifiers can be made of two types of materials: silicone and rubber. When choosing materials, in addition to ensuring safety, it is also important to better realize the soft characteristics of the pacifier. Therefore, most people will choose liquid silicone.

Liquid silicone nipples are generally transparent, food-grade materials; rubber nipples are yellowish, and sulfur content is likely to exceed the potential "disease from the mouth" risk.

Liquid silicone is extremely soft, especially liquid silicone, can be stretched and tear-resistant, for better product shaping. In addition, the softness of liquid silicone can imitate the touch of the mother's nipple, and play a soothing effect on the baby's emotions. Rubber will be hard and difficult to achieve this effect.

![]()

6.2 Liquid silicone bottle

The bottle material has many types, glass bottles have always been the first choice of the mom group. But as the baby grows up, he will like to hold the bottle to eat milk by himself. At this time, the heavier glass bottle will give the baby a sense of weight. The quality of plastic bottles varies, and some plastic bottles have a flavor when scalded by hot water, which affects the taste.

Liquid silicone bottles solve this problem, they not only have all the properties of other materials but also have excellent special properties. Liquid silicone bottles have better elasticity, the elasticity of silicone is different from rubber, and will not be the kind of hard elasticity, the elasticity of liquid silicone is soft and delicate. When the liquid silicone bottle is filled with hot water inside, the touch will be like human skin. Research shows that the touch of the bottle is related to the baby's mood. A good touch helps the baby's emotional stability, which is more helpful for the development of the baby's emotional intelligence.

![]()

7. How to make baby products perform better?

Liquid silicone has excellent resilience, high transparency, thermal stability, anti-yellowing, aging resistance, corrosion resistance and tear strength and other characteristics, moderate viscosity, easy to operate, and high product transparency, you can see whether the casting material in the mold is deformed, there are bubbles and other conditions, is a versatile material, widely used in the mother and baby industry and other fields. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our liquid silicone rubber can meet the needs of the maternal and baby fields and support the provision of diversified customized solutions.