The harm of water vapor on the building often causes peeling between the waterproof layer and the grass-roots level, waterproof layer bulging, and cracking lap joints, which leads to a significant reduction in the life of the waterproof layer. So it needs spray-on silicone waterproofing material to protect the building, and why choose it?

Silicone waterproofing agent specially formulated has excellent hydrophobic, anti-fouling, weathering, and durability to apply maximum repellency for buildings, a new type of rigid waterproofing material with good prospects for application. It can be sprayed on the building surface as an aqueous solution or emulsion, and can also be directly mixed into the cement mortar or concrete in the form of powder as a waterproofing agent. Silicone waterproof agents produce chemical bonding with cement, forming a solid overall rigid waterproofing to improve the mortar and concrete's wearability and durability.

The following six aspects of silicone waterproofing agents in the application of waterproofing:

- What are the dangers of building leakage?

- What are the types of waterproof agents?

- What is a silicone waterproof agent?

- What is the principle of silicone waterproofing agents?

- What are the features of silicone waterproof agents?

- How to make silicone waterproofing agents better performance?

1. What are the dangers of building leakage?

The hazards of water vapor on the building require that the building be waterproof and breathable at the same time. Black roofs can reach a maximum temperature of 85 ℃ in summer. Under the 85℃ sealing condition, water will generate 1.46x108Pa (1445 atmospheres) pressure to the surrounding buildings. As the building is composed of silicate and other inorganic materials, these materials are porous, and permeable, and can greatly attenuate the water vapor travel added to the building on the pressure, but the pressure generated by the water vapor on the building is still very serious, especially in some buildings with poor permeability, this harm is very obvious.

![]()

(1) Water leakage will reduce the durability and safety of the building's engineering structure because there are voids and cracks in the cement products, masonry blocks, and mortar. When the water comes in, if the temperature drops below freezing, then the water ice, the volume of its expansion of about 90%, it will be directly extruded material, resulting in the surface of the material peeling: at the same time squeezing the remaining water inside, so that the material inside also produced stress, thus triggering cracks have further expansion.

(2) The larger the porosity of the material, the more cracks, the larger the water content, and the greater the environmental humidity, the situation is more serious. As the service life increases, this situation is also more and more serious, resulting in the material bond cross-section continuing to reduce cracks continuing to increase, and the bearing capacity of the material also continuing to decline.

(3) The destruction of the protective layer of concrete will also lead to the corrosion of steel bars, and the effective cross-section of steel bars will also continue to decrease; in addition to the corrosion of steel bars, its volume expansion of about 1-4 times, it will squeeze the concrete, which will lead to cracks or cracks to further expand, and even cause the failure of the protective layer of concrete. All these will lead to the reduction of structural durability and safety.

(4) Collective damages caused by water include direct penetration of water, intrusion of rainwater, capillary water and moisture collection in the pores caused when the temperature is lowered to the dew point, absorption of water by water-retaining agents, or moisture seeping from the ground into the walls. In addition, the negative impact of water may also be caused by moisture absorption of salts and microbial contamination.

2. What are the types of waterproof agents?

To protect a building, it is necessary to find a waterproofing agent that prevents the entry of water from the outside without inhibiting the transfer of moisture from the inside to the outside. Waterproofing agents applied to waterproof mortar can be divided into four categories according to their main components:

![]()

(1) Waterproof agent based on chloride metal salts:

This kind of waterproofing agent is easy to cause corrosion of steel.

(2) Waterproofing agent based on sodium silicate (i.e., water glass),:

This kind of waterproofing mortar in the project generally only uses its quick-setting effect and adhesion, to repair leakage and surface treatment.

(3) Water-repellent substances as the base material (fatty acid metal salts):

Although the unit cost of the products is relatively low, its main disadvantage is that the mixing time is long and difficult to disperse and significantly reduces the strength of cement products.

(4) Silicone waterproofing agent:

This type of waterproofing agent has good mixing properties to apply maximum repellency so that the mortar as a whole produces waterproofing and maintains the long-term effect after fully cured, and it has no effect on the bond strength of the surface and has no negative impact on the environment. Preventing water from entering the mortar at the same time, it can also keep the mortar in an open state, allow water vapor diffusion, and not turn yellow.

![]()

3. What is a silicone waterproof agent?

Silicone water repellents are chemicals containing silicone components that chemically bind to the surface of the material to apply maximum repellency. This waterproofing agent has excellent water resistance, weather resistance, chemical corrosion resistance, and other properties, it can effectively improve the waterproof performance of the material to extend the service life. It needs to be used in a ventilated area and fully cured.

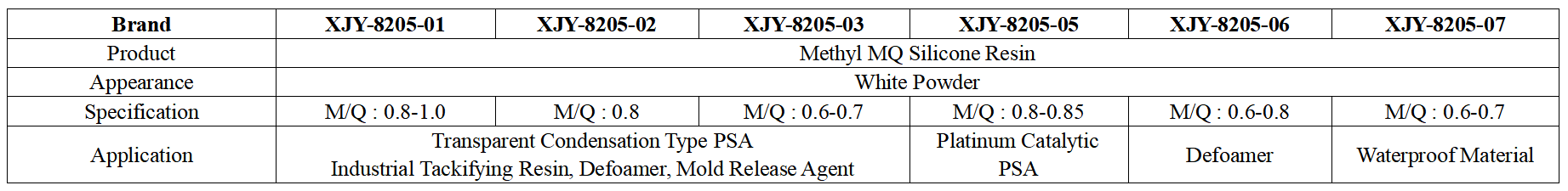

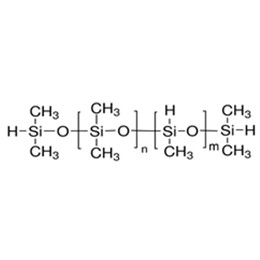

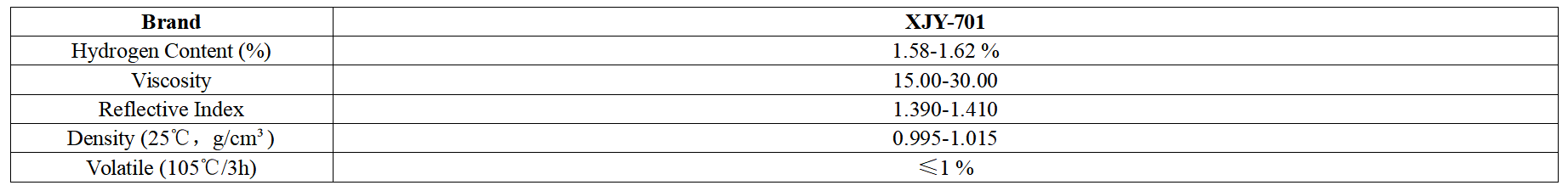

XJY-701 Polymethylhydrosiloxane can be crosslinked to form a film at low temperatures under the action of metal salt catalyst to form a waterproof film on the surface of various materials, which can be used as a waterproofing agent for fabric(such as sleeping bags), artificial marble, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal and so on, and it can be used as a waterproofing agent in the field of construction (such as factory waterproofing).

XJY-711 Hydride-terminated Methylhydrosiloxane/Dimethylsiloxane Copolymer can be used as a water-repellent in buildings and apply maximum repellency.

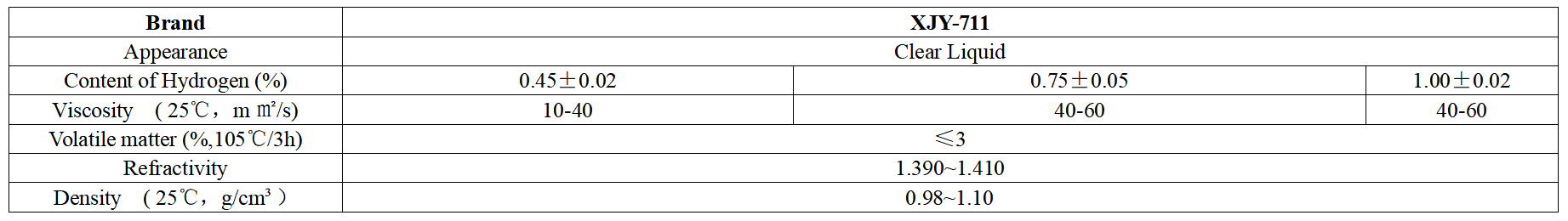

XJY-8205 Methyl MQ Silicone Resin is a solid powdered resin that provides excellent water resistance and forms a durable film. It repels water and stains and can be used as a water repellent specially formulated.

![]()

4. What is the principle of silicone waterproofing agents?

Silicone waterproofing agent is an efficient and environmentally friendly waterproofing material, and its waterproofing principle is mainly based on the special chemical properties of silicone compounds. The active silicon atoms in the silicone waterproofing agent can react with the hydroxyl groups on the surface of the building material to form a chemically bonded waterproof barrier. This barrier not only repels water but is also able to resist the erosion of the external environment, to protect the building materials from water damage (such as factory waterproofing).

In the treatment process of silicone waterproofing agent, it is first necessary to evenly apply the waterproofing agent to the surface of the building materials. Subsequently, the active ingredients in the waterproofing agent will penetrate into the interior of the material and have chemical reactions with the hydroxyl groups on the surface of the material. These chemical reactions lead to the formation of chemical bonding between the waterproofing agent and the building material, thus enhancing the adhesion and durability of the waterproof layer.

As the reaction proceeds, the waterproofing agent forms a dense waterproof layer on the surface of the building material. This waterproof layer has good hydrophobic properties and can effectively prevent water from penetrating through the surface of the material to the interior. At the same time, the waterproof layer is also able to resist the external environment of ultraviolet rays, acids and alkalis, and other unfavorable factors of erosion, and has long-term maintenance of the waterproof effect.

![]()

5. What are the features of silicone waterproof agents?

(1) Efficient waterproofing:

The silicone waterproofing agent formed has excellent hydrophobic properties and can effectively prevent water penetration into the building materials, to ensure the long-term waterproofing of the building safety.

(2) Environmentally friendly and harmless:

Silicone waterproof agent has no harmful substances in the production and use, which is harmless to the environment. At the same time, the chemical reaction between the waterproofing agent and building materials will not produce harmful substances that are harmless to human health.

(3) Strong weather resistance:

The waterproof layer formed by the silicone waterproof agent has good weather resistance and can resist ultraviolet rays, high temperature, low temperature, and other unfavorable environmental factors, to maintain a long-term waterproofing effect.

(4) Construction is simple:

Silicone waterproofing agent construction is simple, it only needs to coat the waterproofing agent evenly on the surface of building materials(as fine mist form). At the same time, the waterproofing agent's requirements for the construction environment are low and can be suitable in a variety of construction environments.

![]()

(5) Wide range of applications:

Silicone waterproofing agent is suitable for a variety of building materials waterproofing treatment, such as concrete, masonry, wood, and so on. In addition, the waterproofing agent can also be used in the basement, roof, wall, and factory waterproofing treatment.

(6) Good permeability:

Silicone waterproofing agent has a certain degree of permeability, which can effectively prevent the accumulation of water vapor inside the material, and reduce the building materials due to moisture damage.

(7) Chemical corrosion resistance:

Silicone waterproofing agent has good chemical corrosion resistance and can resist Acid, Alkali, and other chemical substances, to ensure the long-term stability of the waterproof layer.

6. How to make silicone waterproofing agents better performance?

With its unique waterproofing principle and excellent performance characteristics, silicone waterproof agents specially formulated have been widely used in construction projects. It can not only effectively protect the building from water damage, but also improve the service life and safety of the building. With the continuous development of science and technology, silicone waterproofing agents will play a more important role in the future, this stuff works not only for a single application but also in other fields. How to improve the competitiveness of your products specially formulated?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the construction field and support the provision of diversified customized solutions for large quantity. Add it to your cart add.

![]()