Due to its good properties, silicone sealant is mainly used for bonding, fixing, and sealing in electronics, construction, automobiles, and many other applications. So what's the silicone adhesive?

Silicone sealant is a one-component, non-corrosive silicone adhesive sealant. It uses moisture in the air, to vulcanize forming an elastic silicone adhesive, has excellent non-corrosive bonding for metals including copper, plastic, ceramics, glass, aluminum, etc., and does not require the primer.

The following six aspects of the silicone material is how to apply:

- How to cure silicone sealant?

- Why silicone sealant effect is not good sometimes?

- How to choose silicone sealant?

- What are the precautions for silicone sealant?

- What are the applications of silicone sealant?

- How to make silicone sealant performance better?

1. How to cure silicone sealant?

Silicone sealants surface drying time is generally 5-10 minutes, the surface repair must be carried out before the silicone surface drying. The silicone curing process is developed from the surface to the inside, different characteristics of the silicone surface drying time and curing time are not the same, the curing time with the increase in bonding thickness and increase. For example, a 12mm thick acid silicone sealants may take several days to solidify, but after about 24 hours, 3mm of the outer layer has been cured. In the curing period, a temporary fixing fixture prevents the adhesive from being fully cured and producing any stress before the adhesive force. Due to the size of the interface, temperature, and humidity of the different, it generally needs 7-28 days of curing time.

(1) Initial curing

Under certain temperature conditions, after a while to achieve a certain strength, the surface of the adhesive has been cured not sticky, but the curing closing type is not over. At this time, the adhesive cohesion strength and adhesion properties are very low.

(2) Basic curing

Then after some time, most of the basic to participate in the reaction, and to achieve a certain degree of crosslinking, the course of the general need for a week.

(3) After curing

Generally, at a certain temperature, keeping a period of time to supplement the curing, will further improve the degree of curing and can effectively eliminate the internal stress, thereby improving the bonding strength, the course of the general need for two weeks.

Bonding glass, metal, or most wood, has 20 lb/inch peel strength at room temperature after 72 hours. If the area where the silicone is used is partially or fully enclosed, the curing time is determined by the tightness of the space confinement. In absolute confinement, it is possible to remain uncured forever, and raising the temperature will soften the silicone sealants. The gap between the metal and metal bonding surface should not exceed 25mm, in a variety of bonding occasions, including airtight, bonded equipment before use, it should be fully checked bonding effect.

2. Why silicone sealant effect is not good sometimes?

(1) Long-term water-soaked places should not be constructed;

(2) Not with will ooze grease, plasticizers, or solvents of the material is soluble;

(3) Frost or wet surfaces can not be bonded;

(4) Bonding parts in a completely closed place can not be cured (silicone needs to absorb moisture in the air curing);

(5) The surface of the substrate is not clean or solid, not remove sealant.

(6) The substrate surface temperature of the structural adhesive should not exceed 40 s℃, and of the weathering adhesive should not exceed 50 ℃.

3. How to choose silicone sealant?

(1) When recognizing the brand, you should be all-around to examine and recognize a brand, such as the validity of the registered trademark, past quality assurance, public evaluation, perfect sales network, and service system, etc.

(2) When looking at the packaging, it should pay attention that good product packaging is generally more standardized, such as the outer carton, and packaging tube should be good texture, durable, clear printing, beautiful, factory name, factory address, product name, date, and other relevant information is accurate and detailed;

(3) It should carefully read the product description, the nature of the product, the scope of application, methods of use, precautions, etc. It should be a detailed statement, you can choose according to the material to be constructed, the environment, and functional requirements, but also to see whether the manufacturer has passed the national certification and authoritative testing;

(4) If you test sealant, you can observe the product's appearance transparency, fineness, viscosity, and other preliminary judgments of the quality of the product, in addition, you can also look at the hardness and elasticity, if the requirements are high, especially structural bonding, compatibility testing must be carried out by the state-recognized construction product testing organizations and issued test reports;

(5) Many bonding quality problems are due to the diversity of substrates caused by improper selection of material or changes in the environment, so we recommend that you use the adhesive before the best according to the above aspects of a judgment, the selection of appropriate products in order to avoid unnecessary losses.

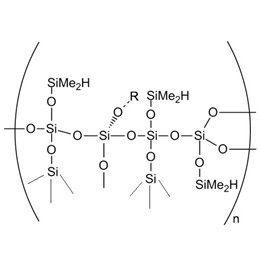

XJY-8207 S/M Hydrogen MQ Resin can be used as a tackifier for silicone sealants to improve the performance of silicone sealants, making them have excellent adhesion.

4. What are the precautions for silicone sealants?

4.1 How to use the glue gun correctly?

Usually applying pressure to the glue gun, the "active axis" is pushed forward and glue is squeezed out to complete the construction process. Then in the process of gluing, the bottle will produce a certain amount of expansion due to pressure, and if you stop the pressure on the glue gun when using, thin bottles contraction recovery from the original expansion, coupled with the glue gun "active axis" of inertia and forward thrust, even if the glue gun to stop applying pressure, the glue nozzle of the glue will continue to flow out a little bit, which will bring inconvenience to the constructor and will affect the quality of construction.

When it needs to stop gluing, you should immediately use your hand to press the iron part of the glue gun spring quickly (usually we can use our thumb to lightly press the glue gun that can), so that the "active axis" forward inertia is reduced to zero because the bottom cover stops being pressurized, the glue bottle expansion and contraction restoration of the pressure will make the bottom cover backward slightly back, which will greatly reduce the chance of glue flow.

4.2 What is the best sealant for an aquarium goldfish tank?

Most of the market uses good imported acidic adhesive for general specification aquarium goldfish tanks. If the width and depth of the aquarium are too large, it is better to use aquarium-specific adhesive (acidic structural adhesive). Cured silicone long-term touch water or immersion will not be too affected.

4.3 Why does silicone sealant not stick firmly or does the aquarium burst?

Several situations may cause this phenomenon:

(1) The specification of the fish tank is too large, the water pressure is too high, and glass or silicone sealants can not load will cause the fish tank to burst.

(2) Glass or silicone sealants have a quality problem or the construction method is wrong.

(3) If the silicone sealants bottle is mixed with air, applying the adhesive will leave bubbles, resulting in the adhesive turning thin, and water pressure may cause the aquarium to burst. Therefore, we suggest that users carefully check whether air bubbles are on the adhesive strip after applying glue. If you find bubbles, you must re-construct.

4.4 Why does silicone sealant turn yellow?

This is mainly the reaction of silicone sealants and PVC tape with more calcium carbonate substances, and calcium carbonate and silicone will react, and there will be a phenomenon of yellowing, which is mainly due to the tape. If you choose a quality assurance silicone sealant product, please check the quality of the tape. If the quality is poor, the magnitude of the yellowing is naturally greater. To avoid this problem, it is best not to use the tape, or choose a good tape. At the same time, we emphasize that before the project with glue, it is best to do a compatibility test to see whether the products are used with other materials and then decide whether to use them.

5. What are the applications of silicone sealant?

Unlike other adhesives, silicone sealant has good substrate bonding, a gap-sealing effect for most materials, and good physical and chemical properties. It can be used for internal and external sealing of buildings, such as curtain walls, doors, and windows, ceilings, floors; it can also be used for automotive manufacturing in the sealing, bonding, waterproofing, dust proofing, etc.; it can be used in electronic products, such as heat insulation; silicone sealant can also be used for aerospace, caulking, bonding, such as shipbuilding, chemical industry sealing.

5.1 Automobile and transportation manufacturing

It is mainly used in the field molding sealing gaskets and automotive engines, windshields, door and window frames, reflectors, exhaust pipes, lights, instruments, containers, trunks, and other water-sensitive equipment adhesive sealing. It has excellent water resistance and lubricant resistance and can be used for water pumps, water tanks, and other water as the medium of the system and the engine, gearbox, cam box, transformers, hydraulic systems, and other lubricants as the medium of the system.

5.2 Electric power

As a result of excellent insulation and thermal insulation properties, low coefficient of thermal expansion; and waterproof performance, the cured colloid can effectively prevent the entry of condensation; corrosion resistance can be guaranteed in the acid, and salt environment for long-term work; excellent aging resistance so that its service life can be up to 50 years, so a large number of insulation used in moisture-proof sealing, environmental protection and anticorrosion, cable accessory products, such as sealing, adhesive, and other aspects.

5.3 Electronics and radio

Room temperature curing silicone sealant is widely used in the field of encapsulation, potting, bonding, impregnation, and coating, etc., on integrated circuits, microfilm components, thick film components, electronic assemblies, or the whole machine for the potting, the components within the adhesive layer can be seen and can be accurately measured parameters of the components.

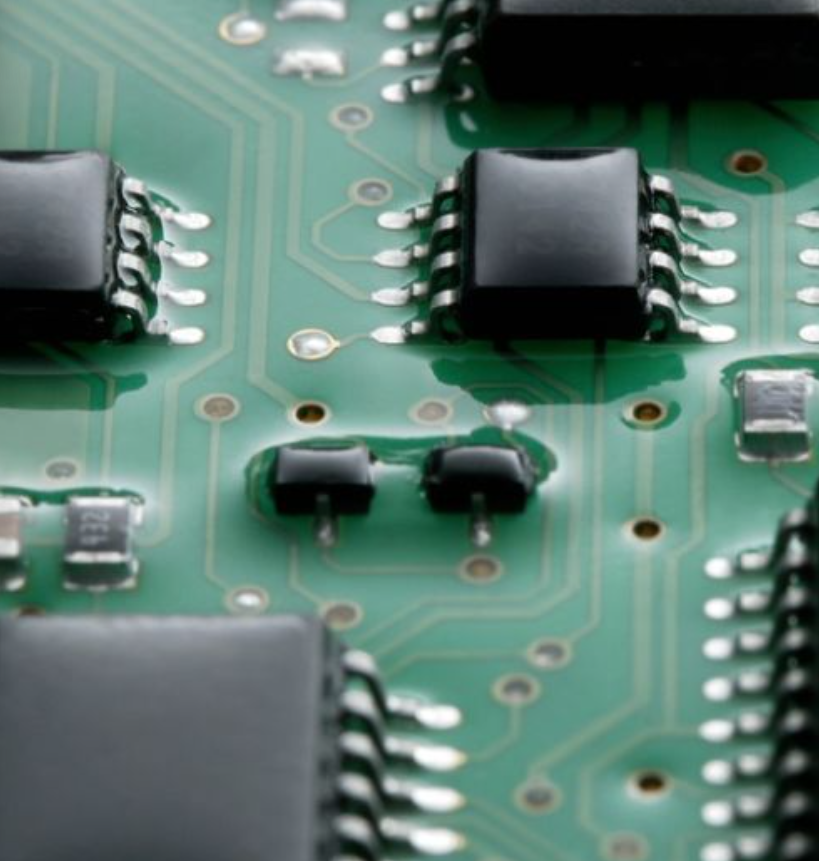

XJY-8205 Powder Series Methyl MQ Silicone Resin is a solid powder resin, which can be used as a reinforcing material for liquid silicone rubber. Adding MQ resin to the potting compound can enhance its resistance to high and low temperatures and prolong its service life. It is suitable for various materials and applied to various electronic components in the power supply, including PCB boards.

5.4 Solar cell adhesive sealant materials

Silicone sealant can be used for solar cell bezel sealant, junction box sealant, busbar sealant, thin-film module bracket bonding agent, etc.

6. How to make silicone sealant performance better?

The main role of silicone sealants is for sealing, bonding potting, etc., with anti-leakage, waterproofing, anti-vibration and sound insulation, and other functions. It is widely used in aerospace, electrical and electronic, airport runways, high-speed rail, high-grade highways, new energy (photovoltaic, wind power, etc.), construction, and other industrial setting. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone resin products can meet the needs of silicone sealants and support the provision of diversified customized solutions.