Fabric softeners are a chemical substance that makes an item soft and used in textile finishing. Fabric softeners smooth the surface of treated fabrics, making the product feel comfortable to the touch and have better antistatic properties, and most fabrics need to be finished with fabric softeners. So why choose silicone softeners in textiles?

Traditional softeners are prone to poor biodegradability and serious yellowing, compared with hydrophilic silicone softeners, it can not achieve the desired fabric feel, fabric hydrophilicity decline, and other shortcomings, but also may produce skin irritation reaction, and do not adapt to market requirements.

Hydrophilic silicone softeners are the emulsion or micro emulsion of Polysiloxane and its derivatives, which can make the fabrics have good softness and smooth feel in soft finishing, non-yellowing plump and elastic feel, as well as anti-wrinkle, abrasion resistance, wash-resistant, and good sewing characteristics, antistatic properties, to a large extent, silicone softeners improve the added value of the product, and thereforesilicone softener is favored by the majority of customers.

Here’s some information about it:

- How to classify the softener?

- How to classify silicone softeners?

- What are the advantages of silicone softener?

- What are the conditions for the use of silicone softener?

- What do you pay attention to when applying silicone softener?

- How to make silicone softener?

1. How to classify the softener?

Softening agent can be divided into two categories: fatty acid derivatives and silicones.

(1) Fatty acid derivatives

Fatty acid derivatives are traditionally widely used softeners, silicone is a new variety of the latter. Silicone softeners are developing rapidly, and new products with various properties and functions are constantly being developed and marketed.

Because silicone softener is not only better than fatty acid derivatives softener effect, and durability is also very good, so in textile softening after finishing use, has occupied the main position. However, it is because its durability effect is good, that removing also brings a certain degree of difficulty, so that back to repair or back to repair the dye treatment becomes difficult. If produce silicone oil spot is more headache, it is difficult to repair.

(2) Silicone

Silicone softener in the ionic, mostly cationic, weak cationic, or non-ionic. Therefore, in the production and processing of color-fixing agents often with the same bath processing, processing bath temperature is generally 30 ~ 45 ℃. Do not wash after softening treatment, after baking the reaction of the film with higher firmness. In order to increase the water solubility of silicone oil, some silicone oil added some self-emulsifier, so that it has a self-emulsifying function in water.

The relative molecular mass of silicone oil used as a softener is generally 60,000-70,000. Hydrophilic Silicone softeners due to their main chain for -Si-O-, are longer than the -C-O- chain, so the molecular chain is softer, with excellent lubrication and soft performance. Silicone softener is suitable for the softening of natural fiber textiles such as cotton, wool, silk, linen, human hair, or all kinds of synthetic fibers.

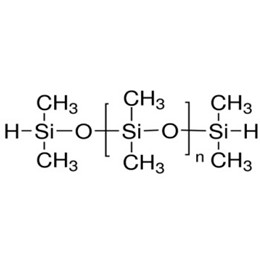

XJY-701-Polymethylhydrosiloxane can be used as silicone softener for synthetic fibers and other blended fabrics.

XJY-707-hydride Terminated Polydimethylsiloxanes can be used as a silicone softener for natural and synthetic fibers.

![]()

2. How to classify silicone softeners?

(1) Dimethicone, light base modified silicone oil

This kind of silicone softener has low cost, is not resistant to washing, and easy to break the emulsion characteristics.

(2) Epoxy-modified silicone softener, Amino-modified silicone softener

These silicone softeners are not hydrophilic, and easy to break the emulsion, and Epoxy modified focus on dry, and Amino modified focus on smooth.

(3) Polyether-modified silicone softener

These silicone softeners have good hydrophilicity, not easily break the emulsion characteristics.

(4) Linear block copolymerization modified silicone softener

This kind of silicone softener has the characteristics: of good hydrophilicity, soft touch, low yellowing, and not easy to break the emulsion characteristics.

![]()

3. What are the advantages of silicone softener?

Natural fibers such as cotton, linen, wool, silk, etc. after bleaching, dyeing, printing processing, or functional finishing, due to wax and oil removal to make the fibers subject to a certain degree of damage, the fabric becomes rougher, darker luster, and even affect the sewing performance, and therefore the need to soft finishing. Synthetic fibers feel worse than cotton, wool, silk, hemp, and other natural fibers, synthetic fabrics after high-temperature stereotypes, the feel becomes very brown and hard, only through the soft finishing to give the fabrics of natural fibers a soft feel, to improve its performance. So hydrophilic silicone softeners are best.

![]()

4. What are the conditions for the use of silicone softener?

Silicone softener suitable working conditions and physical and chemical characteristics, summarized in the following three points:

(1) The work of the PH value of 5 ~ 6.5 is more stable;

(2) The optimal working temperature of 30 ~ 45 ℃;

(3) Ionic, most varieties of cationic, followed by non-ionic; there are individual varieties of anionic (compare the softening effect of various varieties, cationic generally prevail).

![]()

5. What pay attention to when applying silicone softener?

5.1 PH value

The stability of the softener is sensitive to the PH value. In the general dyeing and finishing process, cotton fabrics are pre-treatment, and pre-treatment is usually used with alkali or alkaline substances to remove impurities on the fabric. Some fabrics have to be mercerized, and the alkali used in these processes is not easy to wash inside the fibers, alkali is also used in dyeing with reactive or reducing dyes, so the fabric surface may be alkaline in the finishing process.

Polyester fiber dyed with dispersed dyestuff also needs to go through reduction cleaning, especially the use of insurance powder and caustic soda to do reduction cleaning, if the cleaning is not clean, it will also cause the fabric surface to be alkaline. General silicone oil is not alkaline-resistant, easy to break the emulsion in alkaline conditions, in the softening process of dip-rolling after a period of time will occur after the start of the sticky roller phenomenon, resulting in silicone oil spots.

How to solve it?

(1) Before soft processing, the cloth surface must be washed with an alkaline agent.

(2) Adding acetic acid to the working liquid, and keeping the rolling trough PH=5~6.

![]()

5.2 Speed factor of sizing machine

Dyeing plant sizing machine in the production of ultra-thin fabrics such as chiffon, simulated silk, and bari yarn, the speed is very fast, sometimes up to 60 ~ 80 m / min. However, due to the thin fabric with less liquid, the fabric itself does not have good permeability, coupled with the silicone oil hydrophilic bad, ordinary silicone oil shear resistance is not good, and the fabric brought up on the silicone oil liquid will flow backward on the rollers and easy to cause sticky rollers.

How to solve it?

(1) Trying to control the speed.

(2) Improving the permeability of the fabric.

(3) Using to pay attention to the replacement of rolling through working fluid, often cleaning up the roll.

(4) Improving the shear resistance of silicone oil.

5.3 Cylinder on the softener

In order to achieve a certain feel style and the actual production needs of the factory, some factories tend to do the cylinder impregnation softening finishing. But ordinary silicone oil due to structural factors and residues in the dyeing tank and other reasons, some silicone oil and mixtures will be stained to the cylinder wall, after a long time, the wall of the cylinder will form some black oil viscous material, these things are stained to the cloth will form a silicone oil spot type of spots.

How to solve it?

(1) Strengthen the cleaning work.

(2) Try to use a stable silicone oil in the cylinder.

(3) The cloth surface should be washed before the silicone oil is in the cylinder, do not take alkali; add a little acid as appropriate, PH value adjusted to 6 or so.

![]()

5.4 Silicone oil cohesion phenomenon

In fabrics containing staple fibers such as cotton, T / R cloth, abrasive fabrics, fleece, or wool-eating fabrics, etc., in the process of processing there will be part of the staple fibers fall down, the cloth falls down the short fibers in the rolling groove in the accumulation of silicone oil stained with viscous polymer, these viscous polymer is easily brought to the rolls with the working fluid, the formation of sticky rolls or silicone oil spot. If the water quality is relatively poor, ordinary silicone oil will also coalesce to produce a sticky roll phenomenon and silicone oil spots appear.

How to solve it?

(1) Do a good job of cleaning before driving, and clean up the cloth hair at any time.

(2) Try to wash the cloth surface before applying silicone oil.

(3) Choose good hydrophilic silicone oil, which can reduce the problem of silicone oil coalescence.

5.5 Silicone oil concentration

If the concentration of silicone oil is too high in the process of use, the viscosity of the working fluid is too large, it will be easy to produce sticky rollers or crusts, which will produce silicone oil spots; if you put the high-concentration silicone oil original fluid in direct contact with the cloth surface, it will produce silicone oil spots.

How to solve it?

Reasonable setting process, try to make the concentration of silicone oil working fluid not too high, strengthen the operation management, and do not get the silicone oil original liquid to the cloth surface.

More factors affecting the use of silicone oil, preventive measures are to develop a reasonable process, choose a good stability of silicone oil, strictly in accordance with the provisions of the process conditions of operation, to avoid the emergence of factors affecting the stability of silicone oil.

![]()

6. How to make silicone softener?

Silicone softener has excellent softness, anti-wrinkle, anti-static, color protection, moisture management, and other characteristics, its application in the textile, chemical fiber, leather, and other fields is very wide. As people's demand for quality of life is getting higher and higher, the development space of silicone softeners in the textile industry will be more and more. How to make your products more competitive?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone oils can meet the needs of silicone softeners and support the provision of diversified customized solutions.