The history of silicone resins began in the 19th century, and it has true development taking place in the early 20th century. At that time, despite limited knowledge of silicon compounds, the convergence of organic and inorganic chemistry led researchers to synthesize silicone compounds (such as silicone rubber). Initially, the synthesis process was complex and costly and left much to be desired, but researchers persevered and continued to optimize synthesis routes and reaction conditions. Why choose silicone resin?

Silicone resins have dramatically improved their performance, and have emerged in special fields such as aerospace and electronics, showing unique advantages such as high-temperature resistance and insulation. The bonding energy of silicone resins also exceeds the energy of atmospheric ultraviolet rays, so ultraviolet rays cause less aging of silicone resins. In addition, the methyl group in the silicone resin molecule gives silicone resin excellent hydrophobic properties. Silicone resin is non-reactive with other materials and suitable inorganic high-temperature pigmented fillers that can be mixed with each other to prepare high-temperature-resistant powder coatings up to 600 degrees or more.

The following is an introduction to silicone resins from five aspects:

- What is silicone resin?

- What are the characteristics of silicone resin?

- How to improve the performance of silicone resin?

- What are the applications of silicone resin?

- How to improve the performance of silicone resin?

1. What is silicone resin?

Silicone resin is a thermosetting polysiloxane polymer with a highly cross-linked structure, and it has a complex and delicate composition structure. It is usually produced from various mixtures of Methyltrichlorosilane, Dimethyl dichlorosilane, Phenyltrichlorosilane, Diphenyl dichlorosilane, or Methylphenyl Dichlorosilane through a series of chemical reactions under specific conditions. In its structure, organic groups and inorganic silicon-oxygen-silicon main chains are intertwined, forming a unique existence that possesses both organic properties and incorporates inorganic functions.

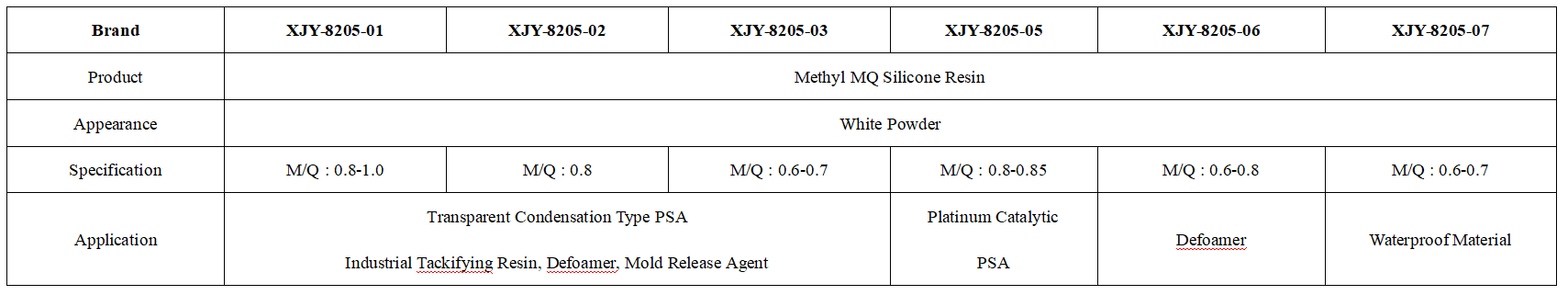

XJY-8205 Methyl MQ Resin

XJY-8205 Methyl MQ Resin (sodium silicate, reaction product with Chlorotrimethylsilane and Isocobalt Alcohol) is the co-hydrolysis product of Tetraalkoxysilane (Q unit) and Trimethylalkoxysilane (M unit) with methyl groups. MQ Resin is widely used in personal care, adhesives, defoamers, water repellents, etc., and it has a good and high mold-releasing ability in release agents for polyurethane processing.

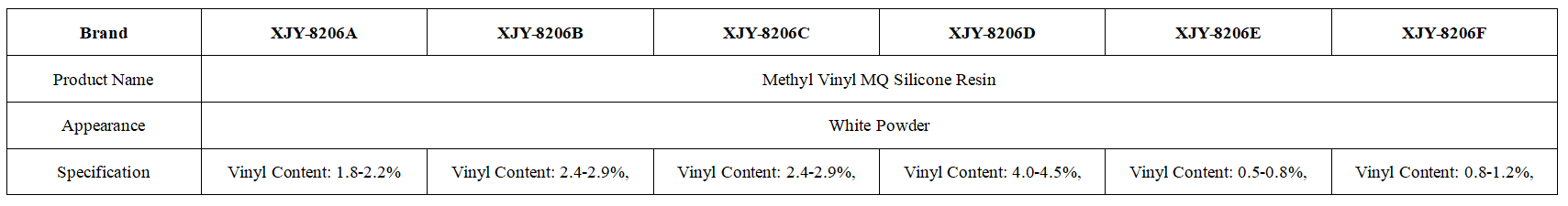

XJY-8206 Vinyl Methyl Silicone Resin

It is condensed from tetrafunctional siloxane (Q) and monofunctional methyl siloxane (M), the molar mass is generally 2500-5000g/mol, and the ratio of the molecular structure of the M and Q chain determines the structural properties of the M resin.

Silicone polymers and silicone compounds made from VMQ materials can provide a wide range of physical properties such as temperature resistance, abrasion resistance, weathering resistance, resistance to permanent deformation in compression, and resistance to ultraviolet radiation. They are harmless to the human body, so they can be used in the automotive industry, medical, and food industries.

2. What are the characteristics of silicone resin?

(1) Thermo-oxidative stability

In terms of performance, silicone resins exhibit impressive thermo-oxidative stability. After heating at 250℃ for 24 hours, the weight loss of silicone is only 2% -8%, compared with 55.5% for Polycarbonate, 65.6% for Polystyrene, and 22.7% for epoxy resin. When the temperature is raised to 350°C and heated for 24 hours, the weight loss of typical organic resins is typically 70 - 99%, whereas silicone resins have a weight loss of less than 20%. This means that it can be used stably for long periods of time at 200 - 250°C without decomposition or discoloration, and for short periods of time, it can even withstand temperatures of up to 300°C. If combined with heat-resistant pigmented fillers, the coatings made from it can withstand even higher temperatures.

(2) Dielectric properties

Silicone resins also have dielectric properties. Its breakdown strength is usually up to 50 kV/mm, volume resistivity is 10^13 - 10^15 ohm-cm, the dielectric constant is about 3, and dielectric loss angle tangent is about 10^-30. This excellent dielectric property can always maintain good insulating properties in a wide range of temperatures and frequencies, and it can be water-repellent to become an ideal insulating material in the electrical and electronic fields.

(3) Low surface tension

Low surface tension is another significant characteristic of silicone resin. Due to the low cohesive energy density of polysiloxane, the intermolecular force is small, and the molecule is in a high state of flexibility, which makes the surface tension of silicone resin significantly lower than other materials. At the same time, the solubility parameters of siloxane and most compounds and materials differ significantly, resulting in poor compatibility, and not easy to mix with other substances, thus giving the silicone resin excellent anti-adhesive.

(4) Weatherability

In terms of weather resistance, silicone resin is also outstanding. On the one hand, the stable Si - O bond in a silicone resin is difficult to produce free radical reaction caused by ultraviolet rays, and oxidation reaction is not easy to occur; on the other hand, the silicone resin is not sensitive to sunlight, and the sunlight has very little effect on it, so it can prevent UV radiation. Therefore, silicone resin can still maintain good performance and appearance when exposed to the outdoor environment for a long time.

3. How to improve the performance of silicone resin?

Silicone resin is not perfect. Although it has excellent hydrophobicity and low water absorption, it has relatively poor resistance to water vapor, especially high-pressure vapor. In addition, silicone resins have limitations when it comes to solvent resistance.

The performance of silicone resins is also affected by a variety of factors. Among them, the ratio of organic groups to silicon (R/Si) in the molecular composition plays a key role. Generally speaking, silicone resins with practical value have a R/Si ratio between 1.2 and 1.6. When the value of R/Si is small, the resulting silicone resin can be cured at lower temperatures; on the contrary, when the value of R/Si is large, the curing of the silicone resin requires prolonged baking at high temperatures of 200-250°C. In addition, the phenyl groups in the organic groups are not as important as the phenyl groups in the silicone resin but are more important than the phenyl groups. In addition, the phenyl content of the organic groups also has an important effect on the properties of silicone resins. The lower the phenyl content, the softer the film, and the faster the shrinkage; the higher the phenyl content, the harder the film and the more thermoplastic it is. When the phenyl content is between 20% - 60%, the film's bending resistance and heat resistance can often reach the best state.

4. What are the applications of silicone resin?

(1) In the field of application, the silicone resin is an “all-rounder”. It can be used to make motor-insulating materials that are resistant to 180°C, such as glass enameled cloth, pressure-sensitive adhesives, glass cloth laminates, mica tapes, impregnating paints, magnetic paints, and so on. With the addition of aluminum powder, it can also be formulated into high-temperature coatings with a long-term resistance of 500°C and an instantaneous resistance of 1,000°C, which are used to coat high-temperature parts such as jet engine tailpipes and metal chimneys. Molded plastics made of glass fibers or asbestos reinforcement can be used as materials for manufacturing arc-resistant switches that are resistant to strong currents and high voltages.

(2) Silicone resins made from Methyltrialkoxysilane are capable of treating paper, plastic, and metal surfaces to give them good brightness and abrasion resistance. In addition, modified silicone resins, such as those modified with alkyd resins, can be used as outdoor coatings with good weather resistance, and are widely used in construction, automotive, and other fields.

The development potential of silicone resin is unlimited. With the continuous progress of science and technology and the increasingly diversified application needs, the research and innovation of silicone resin will continue to deepen. In the direction of research and development, to further improve its comprehensive performance, especially in high-temperature resistance, high-pressure steam resistance, solvent resistance, and other aspects of the improvement.

5. How to improve the performance of silicone resin?

Into the 21st century, along with the rapid progress of materials science and the emergence of new technologies, silicone resin research, and development accelerated, the synthesis method is more and more environmentally friendly and efficient, through the molecular design and modification technology, its comprehensive performance is further improved, not only in the traditional field of the wide range of applications but also to expand to the new energy, biomedicine, and other emerging fields, become an indispensable and important part of the materials field. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the demand for silicone resins and support the provision of diversified customized solutions.