Winter heating boilers and chimneys in the north, in the petrochemical industry, energy, power, metallurgy, and other industrial areas of high-temperature steam pipelines, smelting furnaces, high-temperature furnaces, high-temperature desulfurization equipment, etc., there is a general problem of high-temperature corrosion, if the pipeline surface anti-corrosion protection is not in place, the surface of the pipeline for a long time to endure high-temperature corrosion resulting in pipeline perforation, accidentally will occur in the explosion and other safety accidents. More and more fields for the use of metal materials performance requirements are higher and higher, not only need to be used at higher temperatures but also face a more demanding corrosive environment, so the demand for high-temperature corrosion-resistant paint products continues to increase. Why use silicone high-temperature paint?

With the continuous development of industrial technology, silicone resin with its good corrosion resistance and heat stability, has been developed into silicone high-temperature paint, greatly relieving the chimney flue, boiler, and other industrial corrosion equipment, high-temperature equipment, high-temperature corrosion problems. As a kind of high-temperature resistant paint, silicone high-temperature resistant paint breaks the traditional concept of high-temperature paint, and successfully led to the upgrading of industrial technology. Excellent anti-corrosion performance is widely used in boilers, engine shells, exhaust pipes, chimneys, ovens, and other high-temperature equipment, piping temperature less than or equal to 600 ℃ steel surface.

The following five aspects of the specific performance of silicone high-temperature paint:

- What is silicone paint with high-temperature performance?

- What are the features of silicone high-temperature paint?

- What are the applications of silicone high-temperature paint?

- How to use silicone high-temperature paint?

- How to make silicone high-temperature paint perform better?

1. What is silicone paint with high-temperature performance?

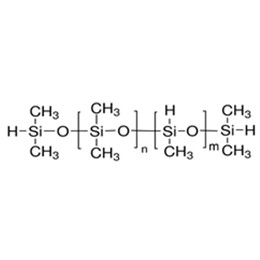

Silicone high-temperature paint is mainly composed of silicone resin, desired color pigmenting, filler, and additives. It is able to maintain stability at extremely high temperatures, effectively preventing the model's surface damage caused by high-temperature oxidation, corrosion, and so on, silicone resin coating has special effects when painted on color effects. In addition, silicone high-temperature paint also has good weather resistance, chemical resistance, and adhesion, which offers good abrasion resistance.

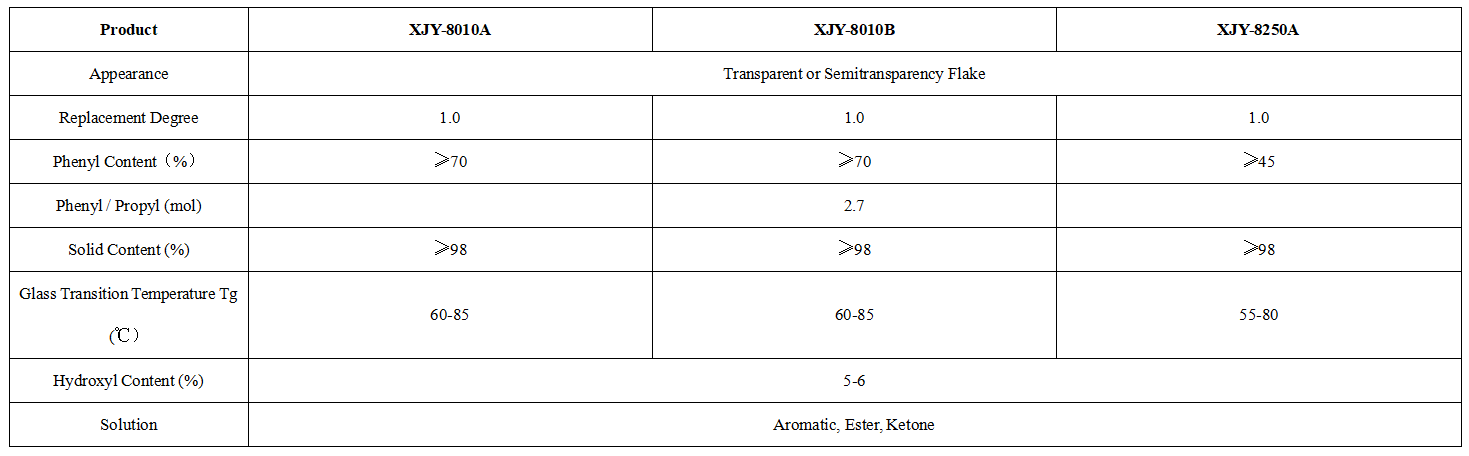

XJY-8010A/B/XJY-83350 Flake Silicone Resin

It can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200°C or even higher temperatures, and can be used to prepare various heat-resistant coatings with heat-resistant insulation grades up to class H. The silicone resin has excellent weathering resistance and can provide all-round protection for equipment. Silicone resins have excellent weather resistance and good adhesion. Silicone thin layers also have excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties. For example, more than 20% of silicone resin-modified coatings have significant water resistance, yellowing resistance, temperature resistance, UV resistance, and other properties, it also can be used for platinum silicone paint bases.

2. What are the features of silicone high-temperature paint?

(1) Excellent high-temperature resistance: Silicone high-temperature paint can be used for a long time under an environment of up to hundreds of degrees Celsius, and the performance is stable, and will not lose the protective effect due to high temperature.

(2) Strong weather resistance: the paint can resist the erosion of ultraviolet rays, wind and rain, and other natural factors, and long-term maintenance of the coating's beauty and performance.

(3) Chemical corrosion resistance: silicone high-temperature paint has good corrosion resistance to acid, alkali, salt, and other chemicals, can protect the equipment from chemical corrosion, and can be used for platinum silicone creations.

(4) Strong adhesion: strong adhesion between the coating and the substrate, not easy to peel, or crack, to ensure that the coating can maintain a long-term protective effect.

3. What are the applications of silicone high-temperature paint?

(1) Aerospace field: aircraft, rockets, and other aerospace vehicles in high temperature, high speed, high pressure, and other extreme environments, the need to use silicone high-temperature paint to protect its surface.

(2) Electric power field: power plant boilers, turbines, and other equipment operating in a high-temperature environment, silicone high-temperature paint can protect it from high-temperature oxidation, corrosion, and other damage.

(3) Petrochemical field: oil refineries, chemical plants, and other petrochemical equipment need to withstand high temperature, high pressure, and corrosive media erosion, silicone high-temperature paint can effectively protect the surface of the equipment.

(4) Metallurgical field: iron and steel, non-ferrous metals, and other metallurgical enterprises of the blast furnace, converter, and other equipment operating at high temperatures, the use of silicone high-temperature paint can extend the service life of the equipment.

(5) metallurgical field: steel and non-ferrous metals and other metallurgical enterprises in the blast furnace, converter, and other equipment operating at high temperatures, the use of silicone high-temperature paint can extend the service life of the equipment.

4. How to use silicone high-temperature paint?

Silicone high-temperature paint is a kind of high-temperature paint that can withstand continuous high temperatures of 300℃~600℃. Paint can be applied to blast furnaces, chimneys, exhaust pipes, heating furnaces, heat exchangers, and high-temperature hot air furnaces inside and outside the wall, as well as other areas of metal materials, non-metallic materials surface of high-temperature corrosion protection.

In the silicone high-temperature paint pre-construction, needs to be sandblasted, and shotblasted to Sa2.5 level of the workpiece exterior treatment.

Specific operation: the object appearance of dust, oil, welding slag, rust, old paint film, and other treatment of cleaning, sandblasting, and shot blasting, to reach the level of construction needs, part of the repair of the appearance of the need to sand to St3 level, common construction techniques are as follows:

(1) Construction environment requirements

Silicone high-temperature paint construction environment temperature of 5 ~ 40 ℃, air humidity should be less than 80%, and the substrate temperature needs to be higher than the dew point above 3 ℃. The temperature of the substrate on the way to construction should be kept as high as possible above 3℃ above the dew point, but not higher than 60℃.

(2) Construction preparation

Silicone high-temperature paint must be stirred before use, such as mixed with foreign impurities should be filtered and used. To prevent the construction of the phenomenon of precipitation. If you need to use thinner to adjust the viscosity, use of silicone high-temperature thinner, pay attention to dilute the paint shall not be poured back into the original barrel. Spraying must be thinned to a viscosity of 18-30cst with a special thinner for high-temperature paint.

(3) Substrate treatment

The surface of the sprayed steel must be thoroughly degreased and descaled, and it is recommended to sandblast the surface to make the steel surface gray and white and paint it within 24 hours so as not to affect the adhesion and water resistance. Substrate treatment is related to the quality of the whole coating and is an important step to ensure the long-term protection of the coating system.

(4) Primer coating

Primer mainly has the effect of enhancing adhesion and anti-corrosion and rust prevention, the adhesion ability to the metal surface is higher than the effect of direct coating paint. High-temperature primer recommended spraying process, coating 1-2, the film thickness can reach 80μm.

(5) Top coating

Silicone high-temperature top coat has good protective properties and a good decorative effect. Silicone high-temperature top coat does not easily change color in high-temperature environments, conventional silver, black iron red, etc., can also be adjusted according to customer needs.

5. How to make silicone high-temperature paint perform better?

Silicone high-temperature paint its unique silicone polymer molecular chain structure, enhances the coating resistance to acid, alkali, and other corrosive substances erosion ability to extend the service life of the equipment; able to resist the sun and rain and other harsh climatic conditions of erosion, to maintain the coating's beauty and functionality; fast drying, strong adhesion, easy to brush, and ambient curing, easy to construct and maintain. How to improve the competitiveness of your products? To inquire about current stock, please contact us.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.

![]()