The market for silicone coatings is showing steady growth. With the advancement of science and technology and the improvement of environmental protection requirements, silicone coatings are widely used in many fields such as construction (silicone roof coating), automotive, electronic, and electrical appliances due to their excellent weather resistance, high and low-temperature resistance, corrosion resistance, and other characteristics. It is expected that in the next few years, the silicone coatings market will continue to maintain the growth trend and make more breakthroughs in environmental protection and sustainable development. How many types of special silicone coating?

- Silicone weathering coatings

- Silicone insulating coatings

- Silicone nuclear radiation-resistant coatings

- Silicone heat-resistant coatings

- Silicone mold release coatings

- Silicone temperature control coating

1. Silicone weathering coatings

Silicone resin has excellent resistance to atmospheric corrosion after the curing process, even in a long period of outdoor UV rays, but also maintains its original luster, and does not appear to chalk, discoloration(metal roofs), or other issues. These highly reflective silicone resin coatings show only a slight loss of luster after up to 12 years of exposure to the sun. It can also be made with a large number of chalking pigments, not chalking paint.

(1) Silicone-modified polyester resin coatings, as a drying-type coating, are mainly applied to the surfaces of materials such as metal sheets, pre-painted metal panels for construction (low slope roofs), and aluminum roofing panels. Its unique weather resistance, light retention, and color retention make the coating maintain its original color and luster after a long time of outdoor use, and it is not easy to fade and chalk. The coating film is tough and wear-resistant, and after seven years of outdoor weathering and ponding water tests, it still does not need to be re-coated.

(2) Silicone-modified acrylate resin coating has excellent weathering performance, light retention and color retention. It is widely used in the pre-painting of metal sheets, polyurethane foam, granulated cap sheet, prefabricated buildings (existing roof), and machinery and equipment. The outdoor weathering use period of this coating is up to 15 years, and it is divided into two types: self-drying type and drying type, in which the drying type is superior in weathering performance.

2. Silicone insulating coatings

Silicone insulating coatings play an important role in the field of insulating materials.

These coatings have a heat resistance rating of 180°C and are categorized as Class H insulating materials. It can be used in conjunction with heat-resistant insulating materials such as mica, glass yarn, glass cloth, and spray foam. Silicone insulating coatings have excellent electrical insulation properties, with dielectric constant, dielectric loss, breakdown strength, and insulation resistance remaining relatively stable over a range of high and low temperatures (-50 to 250°C) and frequencies. In addition, it also has the characteristics of moisture resistance, acid and alkali resistance, radiation resistance, and oxidation resistance.

Silicone insulating coatings can be subdivided into the following categories according to the different uses:

(1) Silicone bonding insulating paint

It is mainly used for bonding all kinds of insulating materials, such as mica, glass wire, etc., with fast curing, strong adhesion, high mechanical strength, and oil and moisture resistance.

(2) Silicone insulating impregnating varnish

It is suitable for the impregnation of coils, windings, and other parts inside motors, electrical appliances, and transformers, requiring low viscosity, strong penetration, and high solid content and bonding force.

(3) Silicone insulation covering paint

It is used for the protection of coils, windings outside, and shells of motors and electrical appliances (open media) to improve their moisture resistance, insulating properties, and chemical corrosion resistance. The drying type has better performance, and the self-drying type is often used for repair.

(4) Silicone steel sheet insulation paint

It is coated on the surface of a silicone steel sheet, heat-resistant, oil-resistant, and insulating properties, which can effectively prevent the generation of eddy currents in the gap between the silicon steel sheet stacked body.

(5) Silicone insulating varnish for telecommunication components

It is suitable for the surface of resistors, capacitors, and other telecommunication components, with the properties of moisture resistance, heat resistance, insulation resistance, temperature change resistance, etc. The paint film has high mechanical strength and good adhesion.

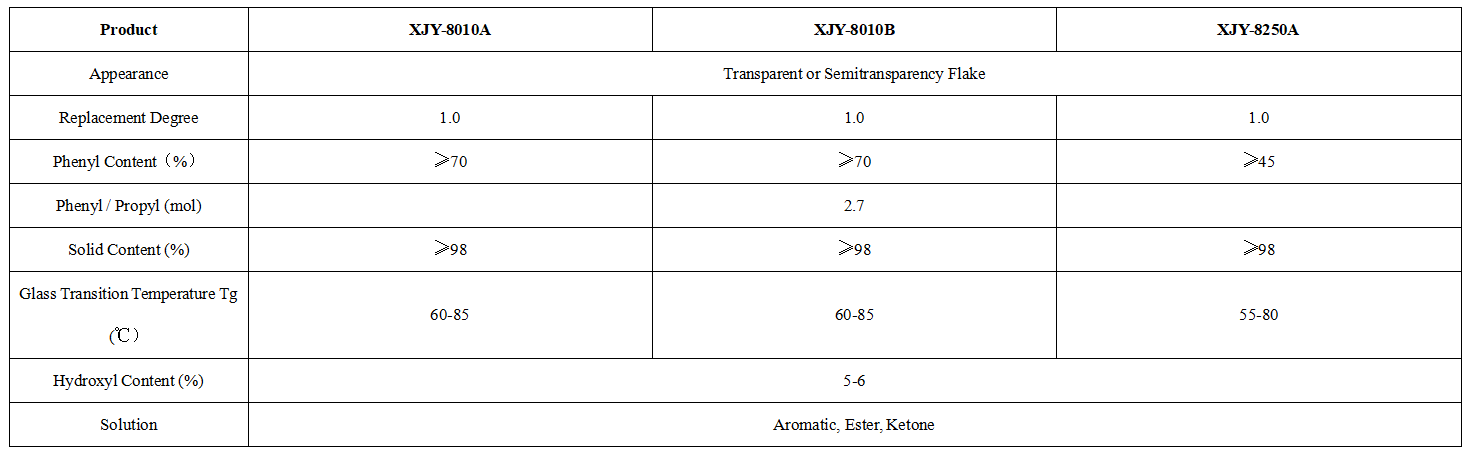

XJY-8010A/B/XJY-83350 Flake Silicone Resin

It can be used for high-temperature-resistant powder coating and liquid coating. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200°C or even higher, and it can be used to prepare various heat-resistant coatings with heat-resistant insulation levels up to class H. The silicone resin has excellent weathering resistance and good adhesion. Silicone resin also has excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties. For example, more than 20% of the silicone resin-modified coatings, have significant water resistance, yellowing resistance, temperature resistance, UV resistance, and other properties.

3. Silicone nuclear radiation-resistant coatings

In nuclear reactors and nuclear power plants, equipment and facilities are often potentially contaminated by radioactive elements such as uranium and therefore require the use of specific coatings for protection and decoration. These coatings must have special properties in addition to meeting the basic requirements of general coatings. Not only do they need to be resistant to nuclear radiation, they also need to be easy to clean and decontaminate. For coatings used in nuclear fuel storage and transportation systems, it is even more important to have excellent chemical resistance and radiation line absorption to ensure the safety of the environment around radioactive sources. In the first level of accident prevention area, coatings also need to be able to 21 ~ 32 ℃ temperature and 50% relative humidity in the long-term stable operation of the environment and need to be through the high temperature and high-pressure steam environment of the harsh test, to cope with the cumulative dose of high-temperature radiation.

4. Silicone anti-heat coatings

Also known as organic ablative coatings, it is a special coating composed of organic polymers as the base material and added inorganic materials. Its design principle is to absorb heat through physical (e.g., melting, evaporation, sublimation, radiation, etc.) and chemical (e.g., decomposition, depolymerization, cracking, high-temperature reaction, etc.) processes at high temperatures in order to reduce the temperature of the coated object. With the development of aerospace technology, organic ablative anti-heat coatings have become indispensable supporting materials.

In the operation of space vehicles, such as missiles, rockets, spaceships, etc., when they travel through the atmosphere at hypersonic speeds or return to the ground, their surfaces will be rapidly warmed up by aerodynamic heating, which may reach 1,000 to 5,000 degrees Celsius. Similarly, the working environment temperature of solid rocket motors is also quite high, about 2,000 to 3,000°C, and accompanied by a pressure of 5 to 20 MPa. To guarantee the normal operation and safety of the vehicle, effective anti-heat treatment must be carried out on these high-temperature parts. Organic ablative anti-heat coatings have become an ideal choice of anti-heat material by virtue of their excellent anti-heat performance, ease of construction, and strong adaptability.

5. Silicone mold release coating

In the manufacturing process of rubber, plastic and other products, molds and products are easy to stick between, which not only affects the surface finish of the products but also may damage the products, reducing the overall product quality. At the same time, the mold cleaning process is also extremely cumbersome, reducing production efficiency. In order to solve this problem, the industry often uses mold release agents between the mold and the product to form an isolation layer to prevent adhesion. This need also exists in industries such as metal casting, glass products, paper, and food.

Since the introduction of silicone polymers into industrial applications, their performance as mold release agents has been widely recognized. Silicone mold release agents have a number of significant advantages:

(1) Excellent heat resistance; heat is not easy to volatile or decomposition, has good oxidation resistance and chemical stability, and is non-corrosive to the mold.

(2) Small intermolecular forces, low surface tension, and most polymer materials are not soluble, and non-bonding, help to maintain the surface of the product clean and improve product quality.

(3) Small amount of use, easy to operate, safe, and easy.

(4) Non-toxic and odorless, especially suitable for food and pharmaceutical industries.

Silicone resin-based mold release coating is a semi-permanent mold release agent. By spraying or brushing diluted silicone resin varnish on the mold surface (non-volatile content of about 15%), and drying at 150 to 200 ℃ for several hours, you can form a layer of silicone resin film. This film can be used continuously tens to hundreds of times, effectively solving the problem of adhesion between the mold and the product.

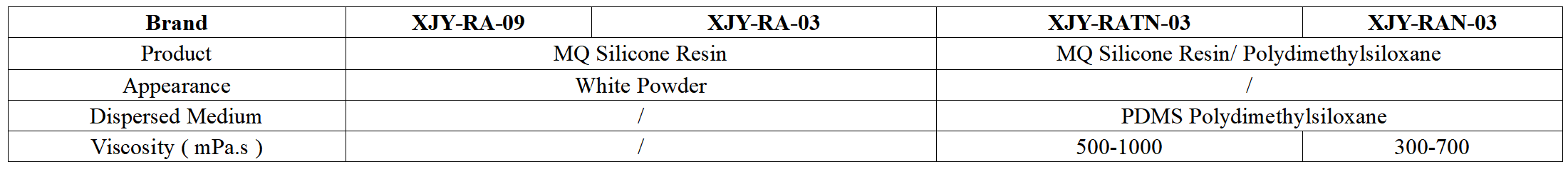

XJY-RA/XJY-RAN MQ Silicone Resin is made of tetrafunctional silicone (Q) and monofunctional methyl silicone (M) polymerization, which has good application effect in the field of high temperature, semi-permanent, and permanent mold release.

6. Silicone temperature control coatings

Spacecraft in orbit flight, need to experience -200 ° C to 100 ° C above the extreme temperature environment, and the work time may be up to several days or even years. However, the structure and equipment of satellites and spacecraft are often difficult to withstand such drastic temperature changes. To solve this problem, researchers have used coatings to coat the surface of spacecraft to change their thermophysical properties, thereby effectively controlling the temperature of the spacecraft during radiant heat exchange. Such coatings are called temperature-controlled coatings (thermally controlled coatings).

By reasonably combining with heat-conducting and heat-insulating materials, temperature-control coatings are able to skillfully regulate the process of heat exchange between the inside and outside of the spacecraft, ensuring that the temperature of the internal instruments and equipment is kept within the permissible range when they are in operation. This is the main role of temperature control coatings.

At present, organic temperature control coatings mainly use organic silicone resin or silicone rubber as the paint base. The lacquer made of high solids materials not only has excellent thermo-optical properties but also has a low outgassing rate in high vacuum environments, with a weight loss of less than 1% and a volatile combustible content of less than 0.1%, which ensures the safety of use. Since the benzene substituent may lead to discoloration, alkyl-capped methyl silicone resins, and room-temperature vulcanized methyl rubber are often used in practical applications.

7. How to make silicone coatings perform better?

The high performance of silicone - heat and UV resistance of resins, smoothing and leveling properties of additives, defoamers, and adhesion promoters - have been widely used in the coatings field. In recent years, however, newly developed products combining silicone materials and organic polymers have shown marked improvement over traditional silicone coatings and pure organic coatings. More and more formulators are discovering the versatility and durability of silicone materials so that the boundary between silicone and organic systems will become more blurred. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.