The 21st century is the era of health, but also the era of rapid development of life sciences. Silicone as a new material has been successfully applied to all aspects of the medical field, but currently in China is still in its infancy, I believe that there will be greater opportunities for development in the future. The synthesis of silicone compounds has a history of more than 50 years. What about medical silicone?

Medical grade silicone materials have unique properties, such as good biocompatibility, non-skin sensitization, physiological inertia, non-toxic, odorless, extreme temperature resistance, good air permeability, unique solution permeability, and stable physical and chemical properties. In recent years, it has been one of the research hotspots in human medical materials, the pharmaceutical industry, silanization reagents, and genetic engineering, and has been widely used in the field of medicine and development, which is a typical technology-intensive and high-value-added product.

There are 3 aspects of introducing medical silicone:

- What are the types of silicone materials?

- How to apply medical silicone?

- How to make medical products better performance?

1. What are the types of silicone materials?

Polyorganosiloxane is a class of molecular structure that contains at least one SiC bond and Si-O - Si bond polymer. There are many varieties of silicone compounds, according to their structure and form, and they are mainly divided into the following five types.

(1) Dimethicone

Dimethicone is completely methylated linear polysiloxane, according to the different degrees of polymerization, molecular weight, and viscosity changes, can be a colorless transparent thin fluid to highly viscous paste semi-solid, non-toxic, colorless, odorless, non-skin sensitizing, bioinert and biocompatible, good resistance to extreme temperatures, etc., but also has good anti-foaming properties. This most versatile material is widely used in eliminating bloating and gastrointestinal distension, pulmonary edema, defoaming of gastric juice before gastroscopy, defoaming of blood in artificial blood circulation devices, skin care, treatment of burns and scalds, and as a drug dispersant in the drug slow-release system.

![]()

(2) Polyether-modified silicone oil

Polyether-modified silicone oil polyorganosiloxane side chain is partially replaced by hydrophilic polyethoxy (E0)-polypropoxy (PO) nonionic groups, and thus has good surface activity, by reducing the surface tension of the liquid, wetting, dispersing, emulsifying, and other effects, are some of the pharmaceutical silicone oils and other raw materials ideal emulsifiers, has been reported as a nonionic surfactant for pharmaceuticals!

(3) Methyl hydrogenated silicone oil

Methyl hydrogen-containing silicone oil is a colorless or yellow transparent oily liquid, the side chain contains a certain proportion of active hydrogen, and can be used as a reducing agent for the organic synthesis of drugs.

(4) Silicone rubber

Medical grade silicones rubber for linear polysiloxane through the addition, condensation, peroxide, radiation, and other methods of crosslinking curing the formation of elastic polymers with high-strength elastic bonds. It can be applied to the skin or implanted in the human body as a drug release carrier; silicone rubber tubing can be used for drugs, body fluids, and drainage. The European Pharmacopoeia contains silicone rubber elastomer implants and catheter products.

![]()

(5) Organosilanes and silane coupling agents

Organosilanes and silane coupling agents are a class of organic compounds with a special structure, which can be hydrolyzed directly on the silicon atom with groups such as halogen, alkoxy, etc., silane coupling agents can also contain active groups such as amino groups, epoxy groups, such as base. Mainly used as chemical modification silanization reagents, such as dimethyl dichlorosilane, trimethyl gas silane, hexenyl trimethoxysilane, etc.

Toxicology and biocompatibility evaluation of silicone materials for medical use The most widely used silicone in the field of medicine is polydimethylsiloxane and its modified products, with a viscosity 10~100,000MPa-s. The bioactivity and toxicity of the modified polydimethylsiloxane and its derivatives depend on the structure and characteristics of the functional group substituents. Such as polyether-modified polydimethylsiloxane, and polydimethylsiloxane as non-toxic, but may have a certain degree of eye irritation.

2. How to apply medical silicone?

(1) Components of the formulation

Silicone oil can be used as a dressing (excipient, additive) for dermatological drug formulations to assist in the treatment of various skin diseases, such as acne, pimples, psoriasis, fungal dermatitis, hemorrhoids, anal dermatitis, scabies pain, and so on. Silicone oils are used in the formulation of anti-acne and acne medications because of their inherent anti-acne and acne properties. Hexamethyldisiloxane (boiling point 100°C) is added as a volatile component to fungicidal aerosol sprays. This disiloxane has a low surface tension, which improves the coverage of the drug on the skin and also enhances the biological activity of the drug. Silicone oil is not only an effective skin care ingredient, but also for the treatment of burns: ointment containing silicone oil can give the burn patient pain relief and faster disappearance of lumps, and can control infection and promote the generation of granulation: at the same time, it can be used as an adjunct to the treatment of severe burns in a sterile environment to protect the traumatized surface of the skin.

![]()

(2) Silicone defoamer

Silicones used for pharmaceutical antifoaming generally have polydimethylsilicone polyether-modified methyl silicone oil or contain a mixture of organosiloxanes. Silicone antifoam agents in the United States Pharmacopoeia, the United States National Formulary, and the European Pharmacopoeia are also contained.

Pharmaceutical silicone defoamer can be directly added to the gastrointestinal X-ray barium meal or barium enema agent used, but also in the endoscopy before or during the inspection, conducive to the examination and diagnosis; and anti-acid ulcer treatment drugs and promote gastrointestinal emptying of drugs used in conjunction with the elimination of gastrointestinal flatulence, alleviate the symptoms of acid reflux, warmth, bloating, etc., used in the treatment of peptic ulcers, reflux esophagitis, and other diseases; used in the rescue of acute Pulmonary edema, can quickly unblock the respiratory tract, improve the lack of oxygen, reduce or avoid the death of ventricular respiration caused by foam obstruction of airflow, can also be used in the pharmaceutical industry, such as antimicrobial fermentation defoaming and so on.

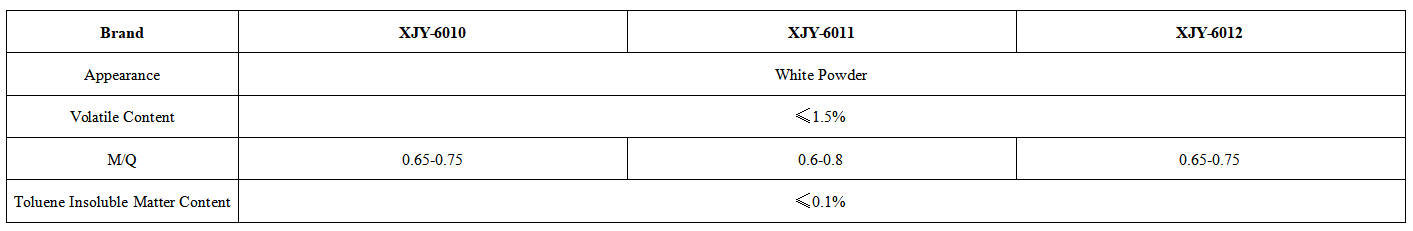

XJY-6010/XJY-6011/XJY-6012 Methyl MQ Silicone Resin is a solid powder resin. This resin provides good antifoaming and hydrophobic properties and eliminates existing foam.

(3) Silicone Rubber

Medical silicone rubber tubing is widely used as peristaltic pump tubing for drug delivery in various M P pharmaceutical factories: this rubber like material can also be used in extracorporeal circulators, external and internal drainage catheters, interventional therapeutic catheters, implantable catheters, and can be cleaned in situ. Polysiloxane can also be used in the field of medical testing and analysis, such as human tissue and blood anesthetic content tests.

![]()

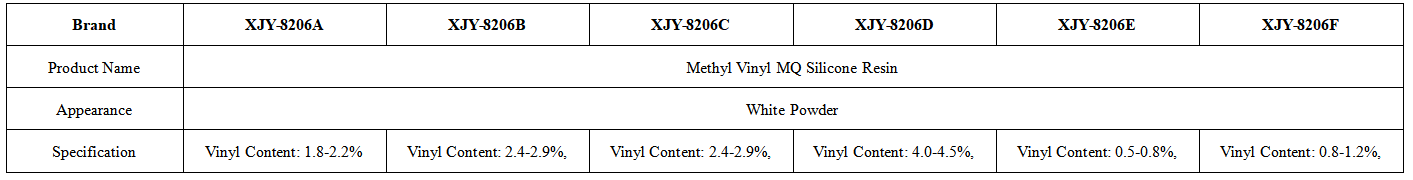

XJY-8206 Methyl vinyl MQ Silicone Resin

It is a solid powder resin, which can be used as reinforcing filler for additive molding silicone rubber (high consistency rubber), and also as having high transparency and high hardness.

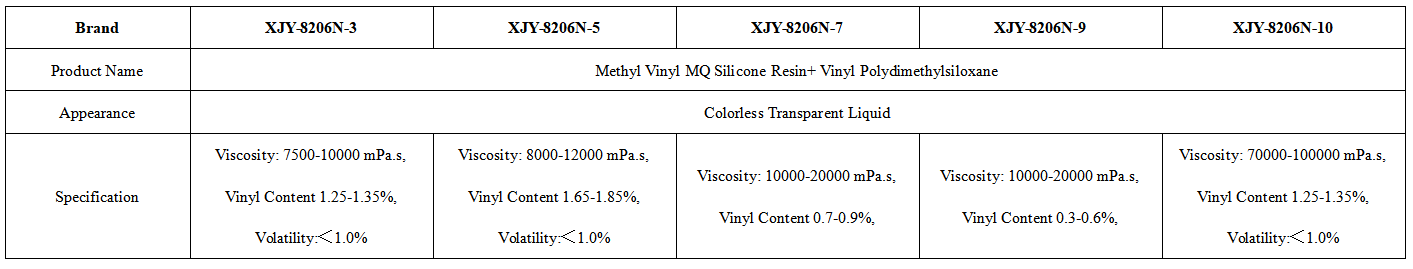

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Dimethicone

It is a colorless and transparent liquid silicone rubber LSR, composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used in liquid silicone rubber and other additives, but also has good reinforcing and hardening properties, widely used in the medical field.

3. How to make medical products better performance?

Silicone materials of low chemical activity, low surface energy, and significant hydrophobic properties, to a certain extent, the decision of the material has very good biocompatibility. Silicone materials are widely used in medical applications by device manufacturers, medical silicone adhesive, chemical process, pharmaceuticals, biomedical materials, personal care products, food, and other long-term contact with the human body or related fields (medical device manufacturing), such as silicone rubber implants and catheters used in medical devices class I and class III a variety of medical products, including intrauterine contraception, hydrocephalus shunt, extracorporeal circulation in cardiac surgery, artificial organ implants and so on. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical-grade materials and support the provision of diversified customized solutions.