As consumers' demand for textile quality continues to improve, the use of fabric softeners has become an important means to enhance textile quality and market competitiveness. Through softening treatment, textiles can obtain a softer, smoother, and more comfortable touch to meet consumer demand for high-quality textiles. Why choose silicone softener in textiles?

Silicone softener is a high-quality textile auxiliary material. It is a millimeter-grade transparent liquid with excellent softness, antistatic properties, flatness, lubricity, and high-temperature resistance. Silicone softener is widely used in the textile printing and dyeing industry, which can make the fabric smooth and soft, breathable, and comfortable to the touch, and can improve the color fastness and durability of printed and dyed products.

There are 6 aspects of introducing silicone softeners:

- What are the structural characteristics of silicone?

- What is the performance of silicone?

- What is the softening principle of silicone?

- What is the principle of high-temperature resistance of silicone softener?

- What about the application of silicone softener?

- How to make silicone softener better performance?

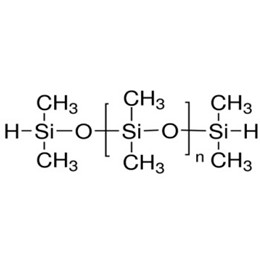

1. What are the structural features of silicone?

Structurally, Polyorganosiloxane has the following characteristics:

(1) The main chain Si-O-Si bond for the inorganic structure, the side chain for the organic group, and therefore is a typical class of semi-inorganic, semi-organic polymer.

(2)The bond angle of Si-O-Si bond on the main chain (∠Si-O-Si) is 130°~145°, the bond length of Si-0 bond is 0.163nm~0.164nm, and the bond energy is 367.8kJ/mol. compared with the same family of carbon and oxygen compounds (bond angle COC108°, C-O bond length 0.142nm, and the bond energy is 357.4kJ/mol), polysiloxanes have a large bond angle, long bond length, and long bond energy. The main chain is characterized by large bond angles, long bond lengths, and high bond energies.

(3)The bond angle of the side chain C-Si-O is 160°, and the bond length of C-Si is 0.188nm, so the activation energy required for the rotation of the side chain methyl group around Si-O is low, only 8kJ/mol.

(4) Polysiloxane main chain Si-O inter-dipole and dipole interactions, side chain Si-CH3 interactions: organosiloxane molecules can only be methyl toward the outside, and the silicon-oxygen bond inward to some kind of α-helical structure exists. This unique structure makes polysiloxane chain-to-chain interaction force small, molar volume large, and low surface tension.

2. What is the performance of silicone?

Polyorganosiloxane molecules have the following properties.

(1) Good electrical insulation, flame retardancy, weather resistance, and

(2) Ideal physiological and chemical inertness, non-toxic, non-polluting ecological environment.

(3) Low glass transition temperature, good resistance to high and low-temperature performance, viscous temperature rheology is small.

3. What is the principle of silicone softness?

(1) The softness of silicone is determined by its molecular structure. In silicone polymers, silicon atoms and oxygen atoms are arranged alternately, Polyorganosiloxane in the methyl group is arranged in a directional manner, with a large molecular spacing, so that every silicon atom and its linkage with the group rotating around the silicone oxygen chain of the free energy of rotation is almost zero, can be free to rotate. The carbon-methyl group on the silicon atom can almost completely shield the silicon-oxygen chain while rotating freely. The non-polar methyl group reduces the molecular gravity between the molecular chains, thus giving the fiber a soft characteristic after finishing with silicone.

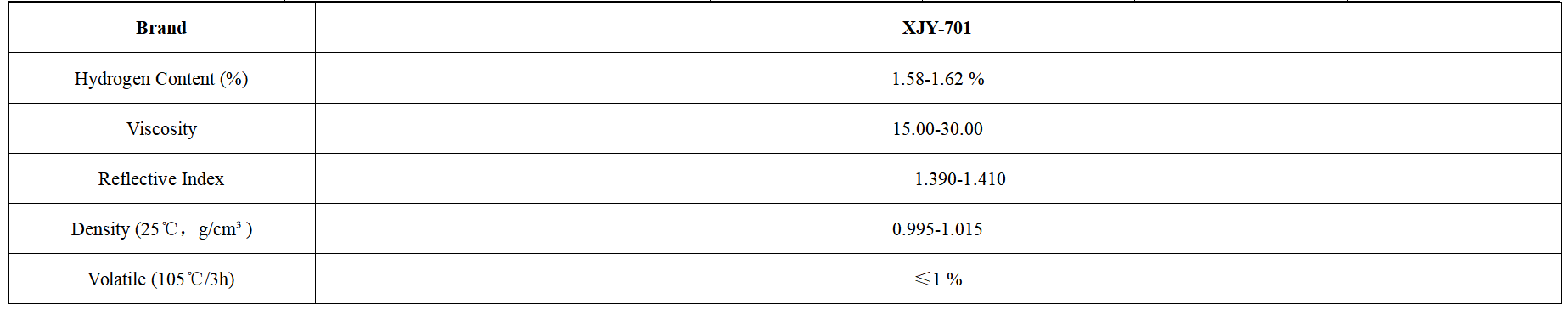

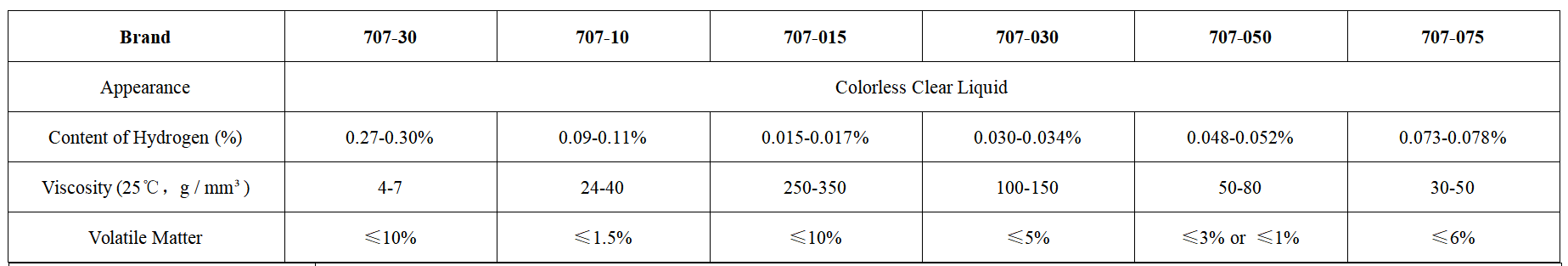

XJY-701-Polymethylhydrosiloxane can be used as hydrophilic silicone softeners for synthetic fiber and its blended fabrics.

XJY-707-Hydride terminated Polydimethylsiloxane can be used as a silicone softener for natural and synthetic fibers.

(2) Mixing silicone structure of the oxygen atom can also be adsorbed on the surface of the fiber, the bond angle of the silicone-oxygen bond can be changed under the action of external forces, and then recovered after the elimination of external forces, so the chain can be contracted, and can be empowered to give the fiber to the elasticity after finishing. This structural property of organosiloxane makes the organosilicon finishing agent the most excellent fabric softening agent.

(3) In many silicone softeners, the amino silicone oil softening effect is most obvious, we think it may be amino silicone oil in the polar group amino can be a more effective combination with the fabric cloth, so amino-modified polysiloxane can be very firmly oriented and adsorbed in the fiber (see the figure below), which reduces the coefficient of static friction of the fibers, with a very small force can be made to the beginning of the sliding of the fibers between the fibers, so as to give fabrics Better smoothness.

4. What is the principle of high-temperature resistance of silicone softener?

The high-temperature resistance of silicone softeners mainly depends on the dimethylsiloxane molecule in its composition, which is very stable and chemically inert and will not react with the fiber raw materials. Therefore, in the textile production process, even at high temperatures, silicone softeners will not degrade in quality or degradation, to achieve long-term stability of the soft effect, and will not pollute the fabric or affect the feel.

5. What about the application of silicone softener?

As an important textile auxiliary material, silicone softener not only has excellent softness, lubricity, and leveling properties but also has excellent high-temperature resistance. The addition of silicone softeners in manufacturing not only improves product quality and competitiveness but also reduces production costs and recycling rates.

Silicone softeners can be applied in the treatment process of a variety of fiber raw materials, including cotton, linen, silk, wool, and other natural fibers and synthetic fibers such as polyester, nylon, and acrylic. Adding silicone softeners in the dyeing and printing process can improve the softness and feel of fabrics, reduce the pilling and linting on the surface of fabrics, and static cling, and increase the best-selling rate of products.

In the textile finishing, silicone softener can be used to soften the fabric and improve the feel and comfort of clothing, but also anti-wrinkle, and anti-fold, in the fabric surface to form a layer of soft, durable silicon film.

Silicone softeners can also be used in rubber surfaces plastic surfaces and other soft finishing.

6. How to make silicone softener perform better?

Silicone softener is a widely used softener, that can increase the softness and silkiness of the fabric, improve the feel and slip, greatly improving the comfort and texture of the fabric. Its main working principle is to form a micro-thin film of silicone molecules on the surface of the fabric, so that the softe fabrics surface becomes smooth, with good tear strength softness, and abrasion resistance. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the textile field and support the provision of diversified customized solutions.