The soles of shoes are mainly foam materials, PU foam soles, PVC foam soles, EVA foam soles, PE foam soles, SBA foam soles, etc. Most of them are polyurethane materials, that is, PU. Before using the release agent, the molds must be cleaned, and the molds, after being used for a period of time, will be left with more and more release agents in the molds, which will affect the quality of the later production. Why apply silicone mold release agent to PU?

As the polymer skeleton of silicone polymer consists of silicone oxygen bonds, it has excellent heat resistance, and can work stably in an environment far higher than the processing temperature of rubber and plastic, avoiding thermal decomposition, carbonization, and other problems in the curing process; easy to form a uniform isolation film on the mold surface, effectively reduce the adhesion between the product and the mold to simplify the process of demolding; silicone release agent components are stable, not easy to migrate, showing a long service life, especially suitable for the need for multiple demolding (such as silicone rubber releasing). It is especially suitable for occasions that need multiple part releases; even at high temperatures, the decomposition products of silicone mold release agents are safe and non-toxic, which is in line with the requirements of environmental protection and safe production. Silicone mold release agents can be used to release a variety of materials and processing methods, such as plastic, rubber, polyurethane, etc., and the mold pollution is small.

The following is an introduction to the application of silicone mold release agent in PU from five aspects:

- What is PU?

- What are the common industrial applications of PU?

- What is the production process of PU?

- What is the use of silicone mold release agent?

- How to make PU better performance?

1. What is PU?

Polyurethane (PU for short) is a kind of organic polymer material that is reacted by polyisocyanate and polyol and has several urethane segments. Raw materials include isocyanate (TDI toluene diisocyanate and MDI diphenylmethane diisocyanate, also known as black material), polyol (PO epichlorohydrin, AA adipic acid, BDO butanediol, PPG polyether polyol, also known as white material), additives (DMF dimethylformamide, MEK methanol ethyl ketone) and excipients (chain expander, catalysts, foam blowing agents, etc.). From the downstream products, polyurethane materials mainly include polyurethane foam (soft foam, rigid foam, semi-rigid foam) and CASE system (coatings, adhesives, sealants, elastomers).

2. What are the common industrial applications of PU?

(1) Elastomers: automobile bumpers, automobile wood-like decorative strips

(2) Fiber: Spandex elastic fiber

(3) Artificial leather: sofas, clothes, shoes.

(4) Coatings: protective and decorative coatings

(5) Adhesives: adhesives

(6) Sealant: Waterproof adhesive

(7) Foam

Rigid foam: industrial materials, furniture

Semi-rigid foam: automotive interior parts - self-skinning as well as general-purpose foam; shoe soles - insole/outsole - microcellular elastomers; shoe soles interlayers

Flexible foam: automotive and furniture seat cushions

3. What is the production process of PU?

Polyurethane is a microcellular elastomer between rubber and plastic, it is a microcellular elastic structure with open holes, the diameter of the bubble holes is 0.01~0.1mm, the free foaming density is 0.25~0.35, (molding density is 0.3~1), usually there is a self-caking skin of 1~2mm, it has superior resilience and great energy absorption capacity. Its density and hardness can be adjusted in a wide range according to the requirements of use, and it can be made into double-color (double-density) double-layer soles, with the lower sole as a micro-foamed highly wear-resistant work surface and the inner sole as a comfortable wearing elastic foam.

Production process:

A, B component raw materials in the raw material preheating oven completely melted, according to the requirements of the A material in the C material (catalyst) and color paste, were added to the molding machine of the original liquid tank, according to the formula requirements and the amount of pouring were adjusted to the two components (A1 and A2 and B) metering pump rotation speed, the two groups of liquid in the mixing device by high-speed mixing and mixing of the chemical reaction occurs, the mixture will be poured into the mold ( The mixture is poured into the mold ( the size of the mold cavity to adjust the pouring time set by the computer programmable controller), the mold is sent to the annular production line baking channel after capping so that it is heated to ripening, after curing the PU products after demolding, trimming, finishing and inspection that is finished products, the mold is sprayed with mold releasing agent and then sent to the casting, the entire production cycle according to the requirements of the original liquid to the ripening of the production line to regulate the speed of the production line.

4. What is the use method of silicone mold release agent?

Polyurethane (PU) is a polymer made of polyisocyanate and oligomer polyol and chain extender or crosslinking agent and other raw materials. In the processing of polyurethane foam blowing molding, it is necessary to get the molded parts with smooth surface, but the isocyanate in the raw material of polyurethane reacts with the moisture and active groups on the surface of the mold and produces viscosity, and at the same time, the polyurethane is easy to be adhered to the surface of the mold due to the polar groups of the epidermis, and the above problems make the polyurethane molded parts difficult to be taken off during the process of production, which causes the defects of the surface of the molded parts, and it will indirectly hurt the mold, and affect the molds. All these problems will make it difficult to come out of polyurethane-molded parts during the production process, causing surface defects in the molded parts. They will also indirectly hurt the molds and affect production efficiency.

Silicone oil-based release agents have low surface tension, are incompatible with polyurethane and most polymer materials, and can form a thin layer on the mold surface, effectively blocking the contact between the polyurethane products and the mold, making it easy for the molded parts to come out of the mold. Silicone mold release agents can be used for polyurethane microcellular elastomers, semi-rigid foams, and self-skinning polyurethane foam products.

For different factories, the scale is different, the process is different, and the production of shoe soles is diversified. There are some differences in the use of mold release agents, but there is a general method of use.

Summarize: take the release agent liquid, proportion dilution, (oil-based with diluent, water-based with tap water), stir Hu, spray gun spraying, blow-drying, mold injection of polyurethane materials, close the mold, and then take out the product soles.

Precautions: Be sure to clean the mold regularly, be sure to figure out whether it is the original release agent or diluted, be sure to dilute according to the ratio, be sure to spray evenly, and then blow-dry dry. For the use of automatic stirring Hu spraying release agent, the dilution ratio must be grasped, because after the stirring Hu, will automatically water in the dilution, dilution ratio plus high, so pay attention to this.

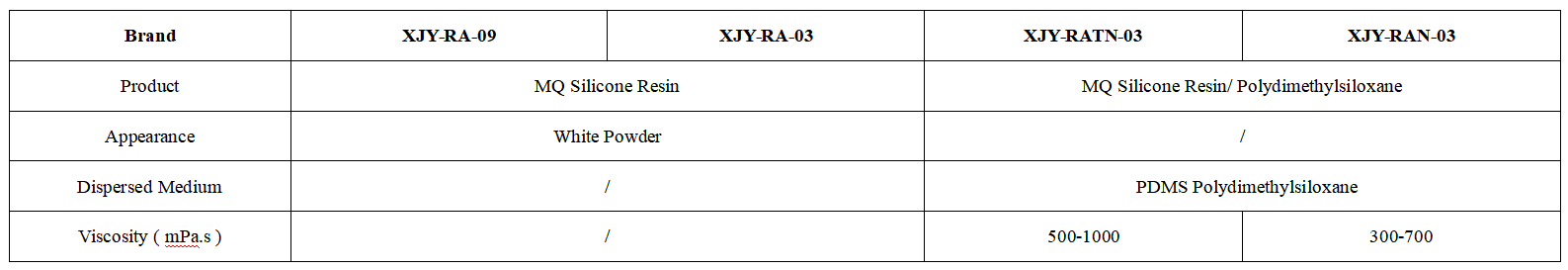

XJY-RA/XJY-RAN MQ S Silicone Resin

It is made of tetrafunctional silicon (Q) and monofunctional methyl silicone (M) polymerization, in the field of silicone high temperature, semi-permanent, and permanent release agents. Silicone mold release agents are specially formulated to be resistant to high and low temperatures, have low surface tension, and are non-corrosive to metals. Adding silicone resin (5-15%) can significantly improve the strength of silicone oil film, in the field of high-temperature casting and other areas of good application.

5. How to make PU better performance?

Non-migratory silicone mold releasing agent based on silicone resin, the components are stable and non-migratory, showing a long service life. Part of the silicone mold release agent to water as a medium, environmental protection and easy to deal with, after coating the water evaporation to form a release film, suitable for the environmental requirements of the occasion. How to improve the competitiveness of your products and determine suitability?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the release field and support the provision of diversified customized solutions.