Silicone polymers are polymers containing elemental silicon in the molecular structure and organic groups attached to the silicon atoms, commonly known as polysiloxanes. The repeating Si-O bond is the main chain and is the representative structure of polysiloxane. Polysiloxanes are characterized by low melting points, low glass transition temperatures, and low surface tension.

Polysiloxanes have become important processing aids in the textile industry because of their diverse physicochemical properties. Some typical applications of silicone and its derivatives (e.g. modified silicone fluids and silicone resins) is wide in textile processing. Why are silicones preferred in textiles?

Silicone material has been used in the textile industry since the 1950s due to its versatile physico-chemical properties. Silicone fabric has excellent water repellency and temperature resistance. Therefore, fabric finishing has become the most important application field of silicone. With the progress of the times, the application of silicone in the textile industry has become an important type of cloth additive in various processes.

Here's some information about it:

- What is the main structure of silicone?

- What is the physical form of silicone?

- What are the advantages of adding silicone to textiles?

- What are the applications of silicones in textiles?

- How to make your textile performance better?

1. What is the main structure of silicone?

The main structure of silicone is a silicon-oxygen skeleton surrounded by hydrogen atoms or organic groups. The binding energy of the silicon-oxygen bond is larger than that of the carbon-carbon bond, i.e. the chemical bond is stronger. Therefore, the stability of silicone to high temperature and chemicals is also strong. In addition, the charge of silicon atoms and oxygen atoms differ greatly, silicon - oxygen bond in the covalent bond and ionic bond in the middle state, therefore, is a more stable structure, the molecule to a larger amplitude vibration is also difficult to lap with the neighboring molecules, i.e., the distance between the molecules to become larger, intermolecular gravitational force becomes smaller. Because of this chemical structure, the physical properties of silicone for the surface tension are small, with low dependence on temperature, at high temperature, smoothness of the country smoothness is good. Thus, it is widely used in various processes of fiber processing.

![]()

![]()

2. What is the physical form of silicone?

The physical form of silicone oil, gel, and resin three.

(1) Silicone oil has a chain structure, the freedom of molecular movement, and good fluidity, due to different degrees of polymerization, its viscosity can be freely adjusted. In particular, it is easier to realize the denaturation of the substituent group, and thus the physical properties of the change range are also very large. Such as water repellency to water absorption can have completely different physical properties, and thus silicone oil is the textile silicone most of a class!

![]()

![]()

(2) Silicone rubber molecules have a star network structure. Changing the number of crosslinking points can make the molecular freedom of movement change, especially through the type of crosslinking agent, and the choice of crosslinking conditions, you can get different physical properties of the product. As a fiber processing with silicone, its development prospects are very broad.

(3) Silicone resin cross-linking density, insoluble and insoluble, but its pre-polymer can be dissolved in solvents, the application of such silicone in textile processing, but also to be developed in future research.

![]()

![]()

3. What are the advantages of adding silicone to textiles?

Silicone is a commonly used textile additive, its main role is to enhance fiber abrasion resistance, water resistance, oil resistance, softness and feel, high temperature, and other aspects of performance. At the same time, silicone can also promote the plasticizing of the fiber surface, making it easier to be absorbed by dyes, thus improving the dyeing effect. It is also a wide-use method to attach silicone in the fabric industry, such as in fiberglass

(1) In the processing of textiles, silicone can form a protective film with the fiber surface to improve the abrasion and washing resistance, tear resistance of fibers, and extend the service life of garments. Compared with traditional chemical treatment agents, silicone has better dyeing performance and durability and has a higher cost-effectiveness in terms of service life and use comfort.

(2) Adding silicone additives to cotton fabrics can make them smooth, soft, and shiny. It can also block the penetration of sweat and oil and improve the water and oil resistance of the fabric. Compared with the traditional waterproof treatment, the use of silicone additives can make the fabric dyeing effect more uniform and long-lasting, and at the same time has a better softness and texture.

(3) Silicones are also widely used in high-tech fiber products to improve tear resistance. For example, in the use of high-density long-staple wool made of clothing, silicone can make the fleece softer and more durable, which can increase the comfort and extended life of clothing.

![]()

![]()

4. What are the applications of silicones in textiles?

Textile fiber materials in the weaving molding will usually show a rough feel, hard, garment processing performance, and wearing comfort, as well as a variety of properties are poor, and thus the need for the corresponding surface modification of the fabric to give the fabric a good smooth, slippery, elastic, wrinkle-resistant and other excellent performance.

4.1 Application of methyl silicone oil in sewing threads

Sewing thread is widely used in all kinds of textile fabrics and industrial products, with the increasing varieties and production of fibers, corresponding to the chemical fiber sewing thread oil demand is also increasing.

Chemical fiber sewing thread has high strength, good abrasion resistance, small shrinkage rate, corrosion resistance, and other characteristics, the primary task of the lubricant is to ensure its spinnability in the process. Therefore, the lubricant not only needs to have good drawing properties and reduce the coefficient of friction between fiber and metal but also requires a small moisture absorption rate and weak viscosity.

![]()

The space between the methyl groups can almost cover the complete silicone chain, and the presence of non-polar methyl groups will make the fabrics it finishes softer, reduce the coefficient of friction between fibers, and play a strong lubricating effect.

Polydimethylsiloxane (referred to as methyl silicone oil) has good smoothing properties, not only can significantly reduce friction, but good viscosity-temperature characteristics make it very suitable for use as a chemical fiber smoothing agent, which can significantly reduce the sewing thread processing process of the phenomenon of winding rola. When using it, it needed to wear rubber gloves.

![]()

4.2 Silicone oil in fabric finishing

Silicone oil because of its unique silicone oxygen silicon main chain structure has good leveling, and can be very good in the fiber fabric surface spread penetration, the fiber surface of the convex and concave points, and burr points to fill in the formation of smooth fabric surfaces, and at the same time, due to the silicone oxygen silicon bond energy, bond growth, bond angle, rotational free energy is low, in the fibers after the fiber attached to have a good soft performance, and further improve the fiber! Fabric touch and wearing comfort, through the modification of various functional groups of silicone oil, can also be further endowed to ensure that soft and smooth performance at the same time, to the fiber fabrics to bring a richer range of application properties.

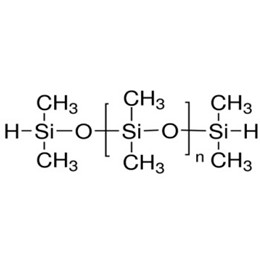

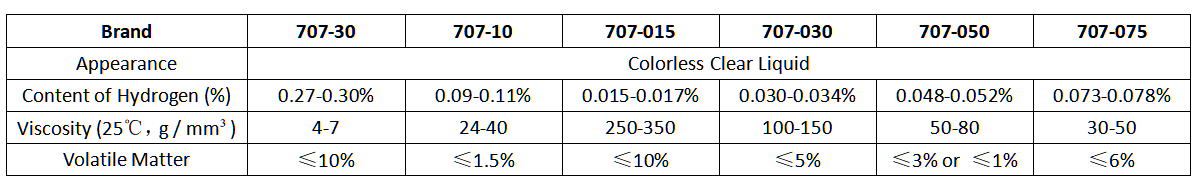

XJY-707 Hydride Terminated Polydimethylsiloxane

It is soluble in organic solvents such as aromatic/petroleum hydrocarbons and insoluble in water. Due to the active hydrogen atoms in the molecular structure, it can be synthesized through the silicone-hydrogen addition reaction of copolymer polymers and can be made into a series of active silicone oils. It can be used to make natural and synthetic fiber softeners.

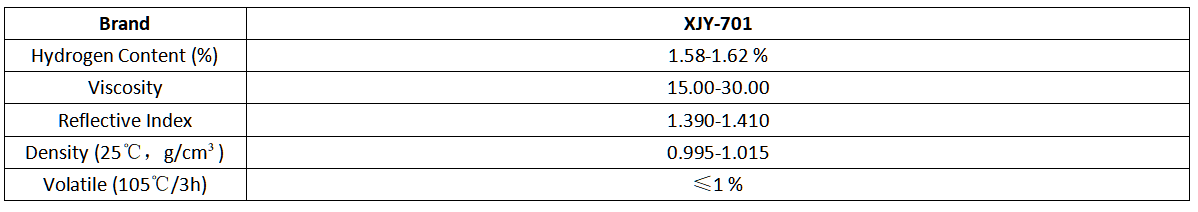

XJY-701 Ppolymethylhydrosiloxane

It can be used as a synthetic fiber softener.

4.3 Silicone resin in the fabric functional finishing

Silicone resin can bring a very unique hand style to textiles, which is naturally dry and non-greasy, and at the same time, it has a number of functions such as anti-wrinkle, anti-shrinkage, and anti-furling.

Wool fabrics will be deformed by felt shrinkage after washing. Silicone resin and emulsion can form a polymer elastic film on the surface of the wool fiber to encapsulate the scaly layer of wool and reduce the directional friction effect to achieve the purpose of anti-felt shrinkage. The emulsion of silicone resin can also bring the effect of deepening the fabrics, the processed fabrics not only deepen the color brightly but also feel soft.

![]()

![]()

5. How to make your textile performance better?

Silicones have many applications, such as adhesive( unlike hot glue, gorilla glue,), and recently become an integral part of the textile industry as an important auxiliary. The chemical has unique advantages in improving the durability, softness, and comfort of fabrics, and has provided a wide range of applications for textile products. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our raw silicone products can meet the needs of the textile field and support the provision of diversified customized solutions.