Silicone rubber is often used in everyday life on a variety of objects. However, there are still some people who feel rusty about silicone rubber and even equate it with rubber, that silicone rubber and rubber are very similar in appearance, and therefore also thought that silicone rubber may be the same as the impression of rubber is not resistant to high temperatures, high-temperature treatment is prone to toxic substances. And such misunderstanding makes a lot of people miss out on the fact that high-temperature resistance, not afraid of falling, environmental protection, and non-toxic excellent material.

The liquid silicone rubber with its non-toxic, environmentally friendly, skin-friendly properties is widely used in the medical, food, kitchen utensils, remote control, automotive instrument panels, and other fields. So what is called liquid silicone rubber (LSR)?

That is the physical type of liquid silicone. Liquid silicone rubber using low viscosity polysiloxane as the base polymer, without the use of messy mixing and molding processing equipment, at room temperature or slightly heated conditions through contact with moisture or with the crosslinking agent mixing, can be vulcanized into an elastomer. Liquid silicone rubber is composed of three parts: base polymer, crosslinking agent, and catalyst. Liquid silicone rubbers have a certain viscosity, and usually will also be a little denser than water, therefore, the fluidity is not as strong as water.

Here's some information about it:

- How to classify liquid silicone rubber?

- What is the difference between liquid silicone rubber and ordinary silicone?

- What is the molding process of liquid silicone rubber?

- What are the applications of liquid silicone rubber?

- How to make liquid silicone rubber performance better?

1. How to classify liquid silicone rubber?

Liquid silicone rubber can be divided into single-component liquid silicone rubber and two-component liquid silicone rubber according to its packaging shape, and its cross-linking mechanism can be divided into condensed liquid silicone and the addition of two types of liquid silicone. A few added liquid silicone rubber can be vulcanized into an elastomer at room temperature, so it is also known as room temperature vulcanization silicone rubber (referred to as RTV rubber).

Combined with the shape of the package and crosslinking mechanism liquid silicone rubber can be classified as follows:

1.1 Single-component liquid silicone rubber:

(1) Condensation-type liquid silicone rubber-RTV:

Deacetic type RTV

De-alcoholized RTV

Deketoxime RTV

Deamidation RTV

Deamination RTV

Deacetonized RTV

(2) Molding liquid silicone rubber-LTV

1.2 Two-component liquid silicone rubber:

(1) Condensed liquid silicone rubber-RTV:

Deketoxime RTV

Dehydrogenation RTV

Deamination RTV

Dehydroxylamine RTV

(2) Molding liquid silicone rubber (RTV, LTV)

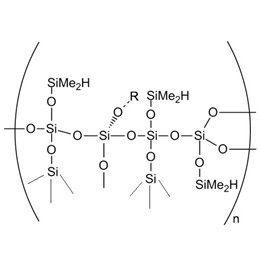

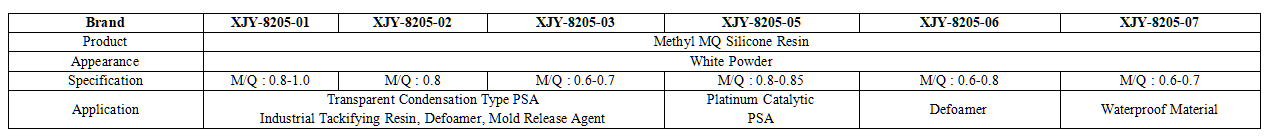

XJY-8205 MQ Silicone Resin is the co-hydrolysis product of tetraalkoxysilane (Q unit) and trimethylalkoxysilane (M unit), which can be used as reinforcing material to make condensation-type liquid silicone rubber (LSR).

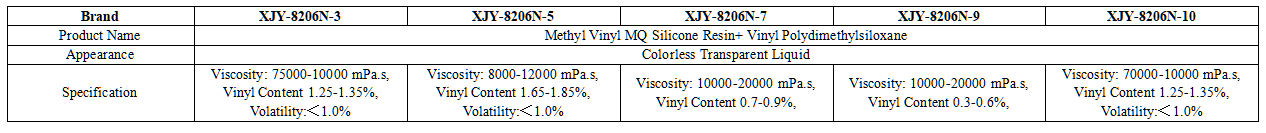

XJY-8206N Methyl Vinyl MQ Silicone Resin / Vinyl Polydimethylsiloxane is a colorless and transparent liquid resin consisting of Vinyl MQ Silicone Resin and Vinyl Silicone Oil, which can be used for LSR Liquid Adhesive Silicone Rubber, as well as other two-component additive adhesives.

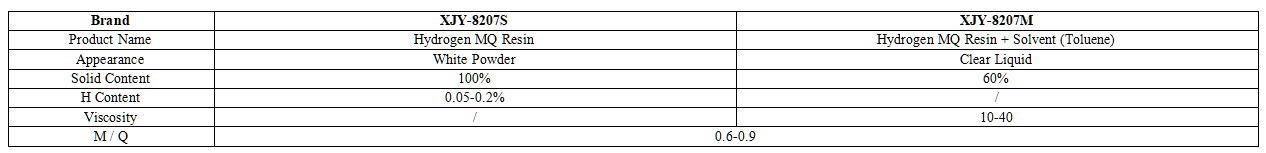

XJY-8207S/M Hydrogen MQ Resin can be used as reinforcing filler for RTV adhesive, HTV adhesive, Liquid Silicone Rubber (LSR), and other two-component addition adhesives.

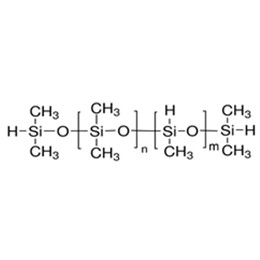

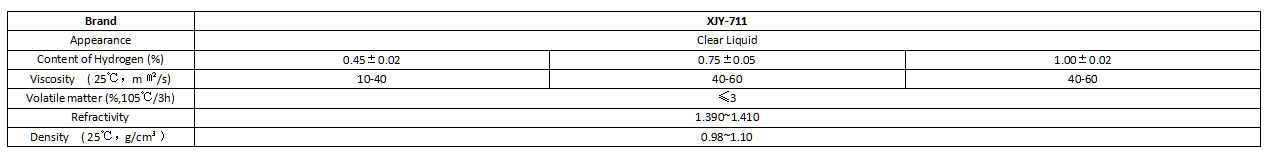

XJY-711-Hydride Terminated Methylhydrosiloxane / Dimethylsiloxane Copolymer can be used as a special crosslinking agent for liquid silicone rubber LSR.

2. What is the difference between liquid silicone rubber and ordinary silicone?

Liquid silicone rubber materials have advantages in the application of gradual discovery by people, instead of many other materials in our daily life. Liquid silicone rubber is different from ordinary silicone material in characteristics of the benefits:

(1) Liquid silicone rubber raw materials have lower viscosity, good fluidity, easy-to-pour molding, and easy of operate.

(2) Liquid silicone rubber curing and material shrinkage is low, less than 0.1%, with good water and moisture resistance.

(3) Liquid silicone rubber stability is good, without the addition of a curing agent (at room temperature below 25 degrees Celsius sealing without moisture, does not meet the high temperature) and can be placed for at least 1 year or more without deterioration.

(4) Liquid silicone rubber has good chemical resistance, acid and alkali resistance, weather resistance, and a variety of chemicals.

(5) Liquid silicone rubber has good mechanical strength, and excellent high-temperature compression resistance, and can be deployed according to customer demand for different strength products.

(6) Liquid silicone rubber has excellent electrical insulation, excellent dielectric properties, and excellent dielectric properties at high temperatures, the dielectric properties at high temperatures greatly exceed those of organic rubber.

(7) Liquid silicone rubber has excellent resistance to high and low temperatures, curing and molding for a long time without deformation; high tensile and tear strength, the number of times the mold is turned over, can be used repeatedly.

(8) Liquid silicone rubber is not limited by the thickness of the product, it can be cured at room temperature or temperature curing molding, non-toxic and tasteless, through the EU RoH Directive, FDA food-grade quality requirements for testing and certification, but also through the extrusion of hot air vulcanization molding and other methods to produce a variety of products.

3. What is the molding process of liquid silicone rubber?

Liquid Silicone Rubber molding, sometimes referred to as Liquid Injection Molding (LIM), is a thermoplastic injection molding process where two compounds are mixed and then thermally cured in an LSR molding tool using a platinum catalyst to create flexible silicone parts. Low compression set and resistance to extreme temperatures make LSR molded parts durable and ideal for challenging applications.

LSR elastomers offer excellent optical clarity, durability, and design flexibility while operating over a wide temperature range (-50°C to 250°C.) The liquid silicone rubber molding process is suitable for the manufacture of complex geometries, due to its design and tooling flexibility, which allows for the combining of multiple functional components into a single part.

3.1 How is LSR different from injection molding?

The liquid injection molding process is very similar to traditional injection molding in the way the part is formed in the mold but differs in the way the part is cured. In an injection molding machine, a thermoplastic resin is melted and cured using pressure prior to injection. LSR is a two-part thermoset compound that is cooled and ultimately cured into the final part before being injected into a heated mold. The molded state of thermoset LSR is permanent and cannot be remixed and reused like thermoplastics. Component A and component B are mixed in a 1:1 ratio and a thermally accelerated reaction occurs, converting the uncured liquid silicone into solid rubber in the liquid silicone rubber molding process.

3.2 What are the advantages of LSR?

(1) It has low viscosity allowing the material to flow easily into thin and complex areas of the mold;

(2) Repeatability of the process and short cycle times compared to molding;

(3) Resistance to bacterial growth and sterilizing capabilities make liquid silicone rubber parts suitable for medical and healthcare products;

(4) Excellent resistance and stability in most consumer environments, almost have no curing and material shrinkage;

(5) Excellent compatibility with human tissue and body fluids;

(6) Excellent chemical resistance;

(7) Suitability for high volume production;

(8) excellent mechanical properties, including good elongation, excellent tear strength, high tensile strength, and wide hardness range.

4. What are the applications of liquid silicone rubber?

Liquid silicone rubber parts is used in a wide range of applications, from consumer electronics to extreme industrial applications, such as Optical-Outdoor, automotive and specialty lightingAutomotive-Lens LED lighting, light guides, optical couplers, O-rings, push buttons, assemblies, gaskets and harness assembliesElectronics-LED lenses, light guides, protective sleevesConsumer products-Nose rests, ear muffs, google, headphonesHealthcare and medical-Medical tubing, endoscope assemblies, catheters, lenses, UVLED lighting, flow control valves, syringe stoppers and other precise silicone rubber parts.

Liquid silicone rubber can be classified into the following 8 types based on properties and applications:

4.1 Mold silicone rubber

Mold liquid silicone rubber is a new type of mold-making material, silicone molds made with mold silicone compared to steel molds in production efficiency and production costs have huge advantages. Today, mold silicone has been widely used in the toy industry, character reproduction, architectural decoration decorative industry, unsaturated resin crafts industry, simulation of animal and plant sculpture, buddha sculpture crafts, and many other industries in mold making, and Polly industrial products.

4.2 Pad printing silicone

Pad printing liquid silicone rubber is used to make pad printing adhesive heads, mainly used for plastic toys, electroplating products, electronic toys, trademarks, and irregular pattern printing. Pad Printing Adhesive Tip is the pattern on the steel plate through the adhesive tip as a carrier, and then transfer the pattern on the steel plate in the toy products. Pad printing liquid silicone rubber can control the hardness by adding silicone oil.

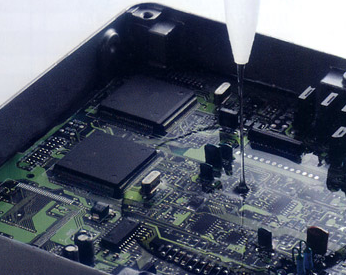

4.3 Electronic potting silicone

Electronic potting liquid silicone rubber is mainly used for electronic products potting, the use of electronic potting liquid silicone rubber can play a sealing of electronic products, waterproof, dustproof, thermal conductivity, shockproof, insulation, and so on. In addition, one is used for LED potting adhesive has high transparency and high refractive index characteristics.

4.4 Silicone Rubber

Hand plate liquid silicone rubber is also known as the first board silicone, usually used for the production of hand plate models, compared to the hand plate oil clay hand plate liquid silicone rubber cured with wear resistance, and strong resilience.

4.5 Silicone adhesive

Silicone glue is what we usually call glass glue, it is also a liquid silicone rubber. Silicone adhesive uses the process of adding a curing agent in an orderly manner, encountering water molecules in the air can be cured into a tough solid, so as to achieve adhesion between the glass gap. Cured silicone adhesive has the characteristics of weather resistance, vibration resistance, moisture resistance, and odor resistance, and adapts to large changes in heat and cold.

4.6 Clothing labeling silicone

Liquid silicone rubber for clothing tags after curing is what we often see in the clothing business silicone tags. The use of liquid silicone rubber to produce clothing tags has a good feel, wear resistance, and high production efficiency.

4.7 High-temperature silicone

Ordinary high-temperature liquid silicone rubber used in the production of silicone molds can withstand high temperatures between 200 to 300 ℃ degrees Celsius, and for aviation and stamping and other industries high-temperature liquid silicone rubber cured can be a long time in the 400 ℃ to 1300 ℃ environment without changes in performance.

4.8 Human body silicone

Human body liquid silicone rubber is a curing hardness of liquid silicone rubber that is non-toxic, on the human body and does not have any adverse effects, so it can be implanted inside the human body, usually used in the production of prosthetic limbs and so on. It can also be used for simulation characters and so on.

5. How to make liquid silicone rubber performance better?

Liquid silicone rubber with its many varieties, excellent functionality, adaptability ease of use, and so on won people's favor, although its development history is relatively short, the speed of development is faster than blended silicone rubber, which is very active in many fields. How to improve the competitiveness of your products?

XJY Silicones is one of the leading manufacturers of silicone MQ resins and VMQ silicones in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone resins can meet the needs of liquid silicone rubber and support the provision of diversified customized solutions.