Sewage treatment needs to degrade the harmful substances in the sewage, and the treated water quality meets the environmental standards and does not cause pollution to the environment before it can be discharged.

In the process of sewage treatment, as the sewage contains some organic and inorganic substances, these substances will produce a large number of bubbles in the sewage treatment process. These bubbles will not only affect the effect of sewage treatment, but also increase the workload of sewage treatment, so you need to add sewage treatment special antifoaming agent. So what is the special silicone antifoam agent for sewage treatment?

Silicone defoamers are high-performance antifoam agents, their main components are silicone compounds and surfactants, which have good performance in aqueous systems and can be used in many applications such as pulp and paper, petroleum industry, and food applications, metalworking fluids. Sewage treatment silicone antifoam agent can reduce the concentration of surfactant, prompting the bubble film discharge way to effectively control the impact of foam in the water treatment, will not react with other chemical additives to produce new pollutants and impurities, to improve the purification capacity of the sewage treatment system, to ensure that discharged sewage meets the appropriate requirements.

Here’s some information about it:

- Why does foam arise in sewage treatment?

- What are the disadvantages of sewage foam?

- What are the advantages of silicone defoamer for sewage treatment?

- How to use silicone defoamer in sewage treatment?

- What are the precautions fors silicone defoamer?

- How to apply silicone defoamer for wastewater treatment?

- How to make the silicone defoamer better performance?

1. Why does foam arise in sewage treatment?

(1) The sewage contains many complex substances, and part of the organic matter has easy foaming characteristics.

(2) The viscosity of the sewage system is high, and a large number of suspended particles are easy to foam.

(3) The sewage treatment system is constantly circulating flow, the faster the flow rate, the more foam is generated.

(4) The addition of chemical additives will contain a lot of surfactant residue in the water.

2. What are the disadvantages of sewage foam?

(1) Too much foam accumulation will overflow the pool and pipeline, the surrounding environment will cause secondary pollution, reduce the use of water treatment equipment, and long time attached to the machine, but also accelerate the corrosion of the machine, reduce the service life of the machine and equipment, clean up around the foam will also be a waste of manpower and resources.

(2) Foam gathered together for a long time will form a foam layer, the pollutants in the foam layer are not easy to remove, but also easy to block some of the filtration port, thus reducing the effect of sewage treatment, harmful substances are not effectively excluded, resulting in the water quality does not meet the discharge standards.

3. What are the advantages of silicone defoamers for sewage treatment?

(1) Silicone defoamers can maintain invariance under high temperature and high pressure, and can effectively adapt to the high temperature and high-pressure environment of sewage treatment.

(2) Silicone defoamer has excellent defoaming and foam inhibition performance, which can effectively eliminate the foam generated in the production process, control foam for a long time, reduce the foam problem in the sewage treatment process, and make the sewage treatment smoother and more efficient.

(3) Silicone defoamer has good water solubility and compatibility in aqueous systems, can be compatible with other sewage treatment agents, and improves the effect of sewage treatment.

(4) Silicone defoamer has low surface tension, superior dispersibility, can be easily dispersed in the sewage foam, and can be used in different temperatures and acid-base conditions;

(5) Silicone defoamer can be diluted many times with water, has good compatibility with foaming medium can maintain good antifoaming and foam inhibition effect at lower concentrations, and does not easily break the emulsion and bleaching oil;

(6) Silicone defoamer is non-toxic, non-corrosive, has no adverse side effects, has good heat resistance, extremely stable, to prevent the growth of microorganisms;

(7) Silicone defoamers can quickly eliminate a large number of foams produced by surface-active substances, water treatment chemicals, fungicides, and so on.

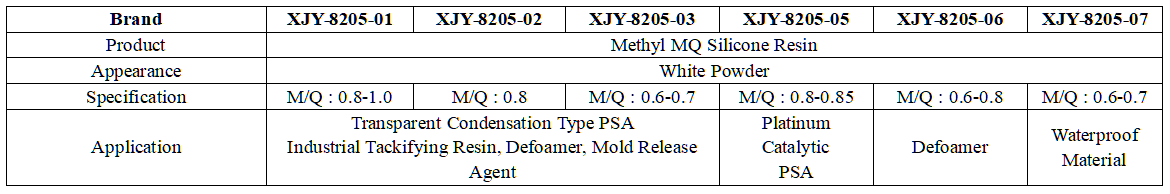

XJY-8205- MQ Resin is the co-hydrolysis product of tetra alkoxysilane (Q unit) and trimethylalkoxysilane (M unit). MQ Resin is widely used in silicone emulsion defoamer and other fields.

Silicone antifoam agent in sewage treatment mainly plays a role in eliminating air bubbles, the elimination of air bubbles is very important because air bubbles will affect the effect of sewage treatment. In addition, silicone defoamer also has the effect of reducing surface tension, improving the defoaming effect in aqueous systems, and at the same time, it has the effect of increasing treatment efficiency, saving cost, and improving the effect, can be used in metalworking fluids, pulp and paper and so on.

4. How to use silicone defoamer in sewage treatment?

The use of silicone defoamer is very simple, only need to add the appropriate amount of defoamer into the treated sewage, mixing fully with a mixer. The amount of use should be based on the treatment of sewage, need to gradually add and adjust the amount of use, to avoid the use of too much or too little.

5. What are the precautions for silicone defoamer?

The following points should be noted when using silicone defoamer:

(1) The amount of use should be based on the treatment of sewage, gradually add and adjust the amount of use.

(2) Do not mix it with other chemical agents to avoid side effects.

(3) It needs to be properly diluted before use to ensure its best effect.

6. How to apply silicone defoamer for wastewater treatment?

Because silicone defoamer has a high defoaming effect and foam inhibition performance, it is widely used in sewage treatment, chemical industry, petroleum, coatings, paper, and other industrial applications. Silicone defoamer for sewage treatment is a highly efficient defoamer specially developed for various water treatment systems.

(1) Silicone defoamer for water treatment can be widely used in various types of circulating sewage treatment, various types of circulating industrial sewage, various industries circulating wastewater treatment, all normal temperatures, alkaline systems of water treatment defoaming, and other types of wastewater treatment process. More is used in the water treatment process, which can be stabilized in the water system foam defoaming and foam inhibition.

(2) Sewage treatment of silicone defoamer can also be used in textile printing and dyeing, leather treatment, papermaking, pesticides, petrochemicals, cooling circulating water, power plants, steel mills, and other water treatment system defoaming.

7. How to make the silicone defoamer better performance?

Silicone-based defoamer is commonly used in many industrial applications, such as metalworking fluids, wastewater treatment, and food processing, and has many advantages, such as reducing surface tension, control foam, reducing the amount of foam, increasing the treatment efficiency, cost savings, and so on. The use should be based on the treatment of sewage, appropriate dilution, and avoid mixing with other chemicals. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone resins can meet the needs of silicone defoamers and support the provision of diversified customized solutions.