With increasing industrialization, the market demand for silicone anti-stick coatings continues to grow. Applications in food, medicine, aviation, and other fields are expected to expand further in the coming years. Why choose silicone release coating?

Silicone anti-stick coating is a commonly used anti-stick coating, and its non-stick principle is mainly due to the special properties of silicone materials. Silicone non-stick coatings are usually coatings consisting of silicone resins, solvents, fillers, and additives.

There are six aspects to introduce silicone anti-stick coating:

- What is the principle of silicone anti-stick coatings?

- What are the advantages of silicone non-stick coatings?

- How to use silicone anti-stick coating?

- What is the application of silicone anti-adhesive coating?

- What is the temperature resistance of silicone non-stick coating?

- How can silicone anti-adhesive coating performance be improved?

1. What is the principle of silicone anti-stick coatings?

Silicone anti-stick coating is prepared on the surface of the substrate with a layer of silicone material coating, the following two main principles:

(1) Bonding principle

Silicone molecules generate chemical bonds on the surface, forming a bonding structure with the surface of the substrate, thus forming a dense coating in the curing process. This bonding principle has excellent corrosion and abrasion resistance and can realize a long-term protective effect.

(2) Bulk principle

Silicone molecules form a non-chemical bonding structure on the surface of the substrate to form a bulk coating. This structure has excellent anti-adhesive properties and high-temperature resistance and is widely used in food, medicine, aviation, and other fields.

2. What are the advantages of silicone non-stick coatings?

(1) High-temperature stability, silicone non-stick coatings have excellent high-temperature stability and can maintain stable physical and chemical properties at high temperatures. This makes the coating in high-temperature conditions also maintain a smooth surface and non-stick, not easily adhering to food or other substances

(2) Low surface energy, silicone non-stick coatings have low surface energy so that the surface is not easy to adhere to other substances. This low surface energy can reduce the food or workpiece and coating surface contact area, thereby reducing the possibility of adhesion.

(3) Chemical resistance, silicone non-stick coating has good chemical resistance, can resist the erosion of acids, alkalis, and other chemicals, and is not easy to chemical reaction, so as to keep the surface smooth and non-stick.

(4) Wear resistance, silicone non-stick coatings usually have a certain degree of abrasion resistance, can reduce surface wear, and maintain the smoothness of the coating and non-stick.

In general, the non-stick principle of silicone coatings is mainly based on its special chemical composition and physical properties, these properties make the coating surface have a better non-stick performance, suitable for cooking utensils, mold, and equipment in industrial production and other fields.

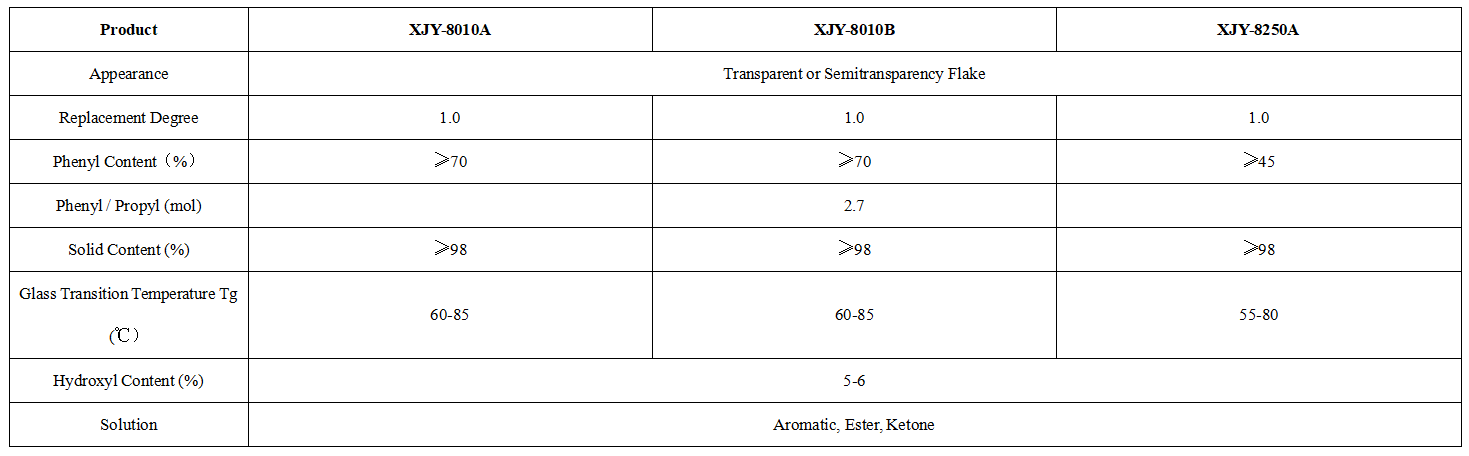

XJY-8010A/B/XJY-83350 Flake Silicone Resin

It can be used for high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200℃ or even higher, and it can be used to prepare various heat-resistant coatings with heat-resistant insulation grades as high as H class. Silicone resins have excellent resistance to radiation and proton oxygen attack. Silicone resins have excellent uv ray resistance and good adhesion. Silicone resin also has excellent weather resistance, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance,e and other properties. It can be used in existing roofs, kitchenware, and so on.

3. How to use silicone anti-stick coating?

(1) Cleaning: Before applying the coating, remove dust, water (moisture), and oil from the surface of the object to be coated and keep it dry.

(2) Masking: If some connectors, sockets, switches, plug boards, and other areas are not allowed to have a coating material.

(3) This product can be constructed by brushing, spraying, dip coating, and other methods. Coating to not flow gossip, no leakage of coating as a limit. The thickness of one coating film is generally appropriate between 0.1-0.3mm.

(4) The first coating film surface is dry, you can apply the second time.

(5) The used-up brush and spray gun should be washed in time for next time.

Precautions

After pouring the glue into the bottle, you should wipe clean the glue at the mouth of the bottle, tighten the cap, and seal it in a cool place. When using it again, if there is a little crust at the seal, just remove it and it will not affect normal use.

4. What is the application of silicone anti-adhesive coating?

Silicone anti-adhesive coating has good characteristics such as high-temperature resistance, corrosion resistance, abrasion resistance, anti-adhesion, etc. It can be widely used in the following fields:

(1) Food processing industry

In the food processing industry, silicone anti-adhesive coatings can be applied to the surface of ovens, baking trays, grills, and other equipment to avoid sticking and improve production efficiency and product quality.

(2) Pharmaceutical industry

In the pharmaceutical industry, silicone anti-adhesive coating can be applied to drug containers, and equipment surfaces, to prevent drug adhesion, adhesion, adhesion, to protect product quality and public health.

(3) Aviation industry

In the aviation industry, silicone anti-adhesive coating can be applied to the surface of high-temperature and high-pressure parts such as aircraft engine blades, guide rudder plates, turbine impellers, etc., to improve the service life of parts and performance stability.

5. What is the temperature resistance of silicone non-stick coating?

The temperature resistance range of silicone non-stick coating is generally between -60℃ and 260℃, but the temperature resistance range of special materials can reach over 400℃. This range depends mainly on the type of material and manufacturing process, and at the same time by the external environment, conditions of use and maintenance,e and other factors.

(1) The basic temperature range of silicone non-stick coating

Generally speaking, the temperature resistance of silicone non-stick coatings ranges from -60℃ to 260℃. This range enables them to remain stable under extreme temperature conditions, thus meeting the needs of various industrial applications. However, it is worth noting that the temperature resistance range of silicone nonstick coatings can vary between different types and manufacturing processes.

(2) Factors Affecting Temperature Resistance Performance

Although the temperature resistance of silicone non-stick coating is excellent, it is still affected by a variety of factors. For example, the humidity of the external environment, oxygen concentration, etc. will have an impact on the stability of the coating. In addition, the conditions of use and maintenance are also important factors affecting temperature resistance. Therefore, in the actual application, it is necessary to choose the appropriate coating material according to the specific conditions and take corresponding protective measures.

6. How can silicone anti-adhesive coating performance be improved?

In addition to excellent temperature resistance, silicone coatings also have electrical insulation, ultraviolet light resistance, corrosion resistance, weather resistance, flame retardant, non-toxic and odorless, and physiologically inert. These characteristics make silicone coatings widely used in aerospace, automotive manufacturing, petrochemical, and other fields. Especially in the high-temperature steam pipe, flue, and other equipment corrosion protection, silicone coatings play an irreplaceable role. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.

![]()