When it comes to healthcare, we all want the best products available to us and our families. We need to make sure that the tools used by healthcare professionals are absolutely safe, clean, and reliable. They want to improve the efficacy of medications and medical devices without sacrificing patient comfort. How can silicones be used in healthcare?

Compatible with body fluids and rubber-like material, medical silicone is the preferred choice, helping to enhance patient comfort and quality of care. Medical-grade silicone has excellent thermal and chemical stability and can withstand repeated sterilization to maintain the performance properties of medical devices. Some medical-grade silicones materials, such as silicon dioxide, and ultra-transparent liquid silicone rubber, offer glass-like transparency and excellent elasticity for use in medical electronics and healthcare devices. Medical silicone can be used in medical device manufacturing a variety of medical devices, coatings, dressings, and artificial organs to meet the diverse needs of the medical field.

The following four aspects of the medical applications of silicone:

- What are the characteristics of silicone?

- What are the characteristics of silicone?

- What are the typical applications of silicone?

- How to make medical products perform better?

1. What are the properties of silicone?

In today's era of rapid technological development, silicone materials, with their unique silicone-oxygen chain link structure, show excellent performance and a wide range of application prospects. The main chain of this material consists of silicon-oxygen bonds, while the side chains are connected to various organic groups, making it flexible and malleable as an organic material while maintaining the characteristics of an inorganic material. Silicone rubber base rubber main chain for the Si-O-Si structure, silicon atoms connected to the group in addition to methyl (-CH3) can also be introduced into other amino, methoxy, and so on. The inorganic silicon-oxygen structure and the molecular structure of organic groups in silicone rubber make it a typical semi-inorganic polymer. The characteristics of this unique molecular structure gives silicone rubber special properties, making it a class of special polymer materials. From the physiological point of view, silicone materials are currently known as one of the most inactive compounds, and other compounds do not have the physiological inertia flame retardant in the chemical process, which is currently widely used in biological, microbiological, and medical industries.

As long as the correct choice of silicone elastomer crosslinking, catalytic system, after full vulcanization of silicone rubber is odorless, tasteless, non-toxic, very resistant to biological aging, has good biocompatibility, and the body tissue reaction is slight, basically harmless to the human body, and basically no adverse effects on the environment, with excellent physiological inertia.

In summary, the medical properties of silicone are as follows:

(1) Biocompatibility: Silicone materials are non-toxic, non-irritating, and have good compatibility with human tissue.

(2) Stability: Silicone in a wide range of temperature and humidity conditions can remain stable and is not easy to decompose.

(3) Flexibility and elasticity: Silicone materials have good flexibility and elasticity and can be adapted to different use scenarios.

(4) Moisturizing and breathability: In care products, silicone can form a breathable protective film with a moisturizing effect.

![]()

2. What is the role of silicone?

As the industry continues to evolve and change, silicones have provided versatile and innovative solutions to the healthcare market for more than 50 years. As the market grows and becomes more complex (e.g., with the introduction of cosmeceutical products), new needs and trends emerge, and the applications for silicones continue to expand. Many silicone applications stem from their unique properties, including their ability to act as film formers and active ingredient delivery systems.

(1) Protection of health

The production of medical and baby care products applied to silicone can achieve the highest quality standards required by health care professionals and their patients. Silicones are antimicrobial, easy to sterilize, and ideal for use in sensitive environments.

Respiratory tubes and topical medications are just two examples. Silicones do not react with other materials and do not irritate the body. There are no adverse side effects or allergic reactions for both external and internal use.

(2) Improving quality of life

Silicones can bring comfort and well-being. Silicones can make materials softer, smoother, and more flexible. It reduces the irritation of topical medications, makes catheters more comfortable, and reduces wear and tear on prostheses.

Medical devices made with silicone have excellent adhesion; elasticity; high stability; antimicrobial; high strength and durability; and are non-reactive with most chemicals and substances.

![]()

3. What are the healthcare applications of silicone film-forming agents?

Depending on their chemical nature, silicones can provide a variety of film-forming properties ranging from transient films and thin surface coverings to stronger, longer-lasting films with self-leveling and adhesive properties.

Two key features of silicone film-forming properties are silicone's affinity for skin and its durability as a film, and silicone's permeability to many molecules, especially water vapor, oxygen and many drugs. Silicone technology not only provides unique properties for innovative healthcare applications, but also enhances the aesthetics of the product, which can improve patient comfort and patient compliance.

3.1 Skin Care

Cosmetic creams, ointments and masks are used in anti-aging products. They have emollient and moisturizing properties. These silicone-based formulations also provide a variety of active ingredients to skin care products.

Applications of silicones in skin care

(1) Moisturizing and Hydrating

Silicones can form a breathable protective film that locks in skin moisture while reducing skin irritation from the external environment. Adding silicones to creams and lotions can significantly enhance the moisturizing effect of the product, keeping the skin soft and smooth.

(2) Anti-aging

Silicones play an important role in connective tissue, acting as a “glue” to bind collagen together, thus enhancing the skin's elasticity and vitality. Studies have shown that silicone supplementation can slow down skin aging and reduce the appearance of wrinkles.

(3) Improved skin radiance

The addition of silicone can give skin care products better spreadability and luster, making the skin look healthier and more vibrant.

3.2 In hair care

(1) Enhancement of luster

Silicones can adhere to the surface of the hair and form a smooth protective film that reflects light, thus increasing the glossiness of the hair.

(2) Reduce frizz

Silicone can improve the smoothness of hair, reduce frizz and make hair easier to comb.

(3) Promote hair growth

Hair itself contains a certain amount of silicone. Each gram of hair contains about 90 micrograms of silicone, which is similar to the silicone content in bones. Organic silicon is an important factor in hair growth and strength, and supplementing organic silicon can promote hair growth.

3.3 Wound care

Wound care is based on skin care and has become a logical extension of utilizing the film-forming properties of silicones to treat damaged skin. Historically, the focus has been on skin barrier applications, including skin sealants. More recent applications include liquid bandages and delivery systems for active ingredients, such as enzymes for debriding necrotic tissue or products for wound cleansing.

Dressings made of silicone provide a moist environment that promotes wound healing and reduces scar formation. These dressings also have good breathability and antimicrobial properties.

3.4 Topical delivery

Therapeutic molecules can also be delivered via film-forming agents for the topical treatment of the skin and its underlying tissues. Well-known uses include analgesic, anesthetic, antimicrobial, and anti-inflammatory applications.

Such products may be packaged and delivered in a variety of ways, such as disposable pouches or tubes (for cream, ointment, gel samples), bottle and brush combinations (e.g., for liquid bandages), sprays, or pressurized containers. In addition, the market for wipes products continues to grow, and ongoing research suggests that various skin-barrier membranes can be used as a means of delivering active ingredients.

4. What are the typical applications of silicone?

As people's concern for health and quality of life continues to grow, the field of nursing and healthcare is constantly innovating and developing. Silicone, as a material with unique properties, is receiving more and more attention due to its wide range of applications in medical care and healthcare. The following are a few examples of the wide range of applications of silicone elastomers in the medical device industry (for component composition) and in the pharmaceutical field.

(1) Adhesives

Medical adhesives are extremely versatile and essential, with benefits including excellent skin bonding properties; longer and more durable effectiveness, even in high humidity; bonding to a wide range of tissues without residue; easy removal of materials such as patches and other materials that adhere to the skin, as well as ease of cutting for use on elbows, knees, and other difficult-to-apply areas; no byproducts; improved absorption of skin patch drugs Absorbability of skin patches

![]()

(2) Dental care

Silicone has excellent stability, tear strength, and non-reactivity and is a key component for compression molding when reconstructing bridges and crowns that require accurate replication of teeth and gingival lines. Silicone also strengthens tooth enamel and prevents cavities while reducing gum bleeding and recession.

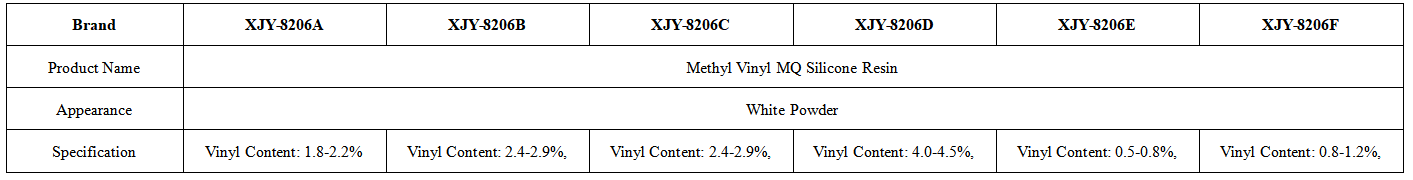

XJY-8206 Methyl Vinyl MQ Silicone Resin

It is a solid powder resin that can be used as a reinforcing filler for additive molded silicone rubber (highly concentrated rubber), with high transparency and high hardness.

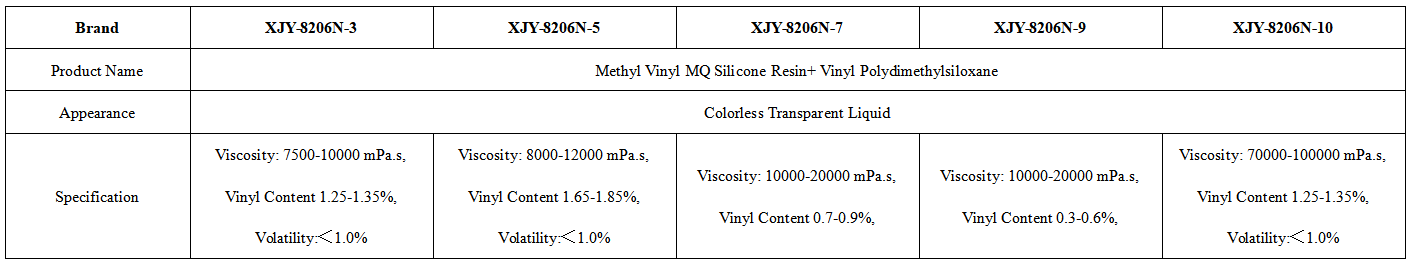

XJY-8206N Methyl vinyl MQ silicone resin + vinyl polydimethylsiloxane

It is a colorless and transparent liquid silicone rubber LSR, composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used with other additives in liquid silicone rubber(high consistency rubber) and also has good reinforcing and hardening properties, widely used in the medical field and electronics (computer chips).

XJY-302 Silicone Pressure Sensitive Adhesive

It is a platinum-cured pressure-sensitive adhesive, that also can be used in the medical field.

(3) Baby Care

Silicones can be used to make strong and durable yet flexible baby bottle nipples, breast pumps, splash valves, and rubber nipples.

(4) Drugs

Silicones can enhance the efficacy of certain drugs and improve absorption. Silicone can be used as an antifoaming agent for the over-the-counter treatment of intestinal gas and can also be used in other prescription drugs. Silicones have excellent absorption properties. When used in transdermal patches, they can help the drug penetrate into the skin, thus improving the efficacy of the drug.

(5) Limb Restoration

Silicones can maximize the stimulation of the skin's properties, bringing unusual cushioning protection and comfort. Materials made of silicone can be molded into the shape of the liner and can be maintained for a long time without deformation. Silicones also inhibit the growth of bacteria, helping to reduce the risk of infection.

(6) Respirators

Silicone respirators are popular with healthcare professionals because they are comfortable, flexible, and easy to clean. In addition, silicone has low allergenicity. Respirator bags made of transparent silicone materials have excellent expansion characteristics and can withstand extreme temperatures.

![]()

(7) Topical medications and lubricants

Silicones make lotions and creams softer and smoother, leaving no greasy residue after use while providing a protective barrier for wounds during the healing process. In topical forms of medication, silicones can improve drug distribution, making it easier and more comfortable to administer medications with a smooth, non-greasy feel. Silicone lubricants can also ease the discomfort of needle and instrument insertion.

(8) Catheters

Catheters are used by healthcare professionals for intravenous drug administration, experimental research, and pacemakers. The use of silicone catheters in some medical devices reduces the risk of infection because silicone does not harbor bacteria and can be easily sterilized.

Silicone materials are also widely used in the manufacture of medical devices, such as surgical sutures, catheters, and artificial joints, due to their biocompatibility and physiological inertness. For example, silicone materials are used as lubricants in hip and knee replacement surgeries to reduce post-operative friction and pain. Silicone materials can also be used to prepare nanoparticles for targeted delivery of anti-cancer drugs, increasing the concentration of drugs at the lesion site and reducing damage to normal tissues.

Silicone Benefits to Consumers and Society Silicone is an important part of healthcare in hospitals, doctors' offices, and at home. Silicones are easy to sterilize, easy to clean, non-irritating, and less allergenic. From dental care to prosthetics, silicones are indispensable for innovative treatments and care that maximize comfort and safety in sensitive environments.

With the continuous progress of science and technology, the application of silicone in the field of nursing and health care will be more promising. Future research directions may include developing more efficient and environmentally friendly silicone care products; exploring the application of silicone in regenerative medicine, such as tissue-engineered scaffolds; and combining nanotechnology and biotechnology to further enhance the performance of silicone in drug delivery and wound care.

5. How can medical products perform better?

The medical properties of silicones were discovered around the mid-1940s, and research began. After more than 10 years of development in the 20th century, in the 1960s, silicone was recognized by researchers to be made into medical products, and foreign media continued to follow this progress. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical field and support the provision of diversified, customized solutions.