Silicone materials combine the properties of organic and inorganic materials, exhibiting many unique physical and chemical features, such as non-toxic and tasteless, weather resistance, electrical insulation, oxidation and UV radiation resistance, low surface energy, biological inertness, flame retardancy, and water repellency, etc, which is widely used in national defense, energy development, light food, textile, machinery, construction, transportation, electrical and electronic industry, medical and pharmaceutical, coatings and paints, daily life and other fields.

![]()

![]()

![]()

![]()

Currently, the core silicone products can be divided into 4 categories, the core of silicone rubber, silicone oil, silane coupling agent and silicone resins. Silicone resins have, in general, more heat resistance than organic resin and have higher dielectric strength and are water-resistant. Silicone resins can be divided into two forms: powder and liquid. The liquid usually solves the silicone resin in different chemicals solvents with little odor. With the excellent compatibility of many organic resins, silicone resins can provide a wide range of films and performance properties for many high-value applications.

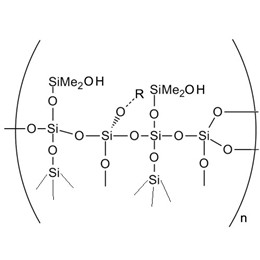

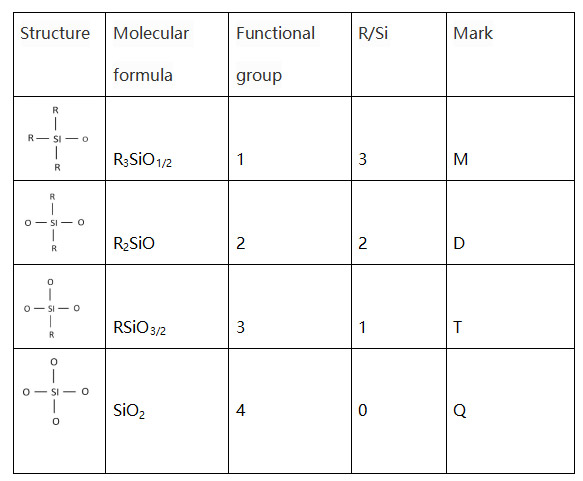

Different structure types of silicone resins

The organic group R is to increase the compatibility with other components for the thickening effect, SiO4 / 2 links mainly improve the strength of the composite material for the reinforcing effect.

Chemical Properties

| Properties | Silicone resin |

| High-temperatures resistance | The thermal decomposition temperature is higher due to the backbone of siloxane. It usually stabilizes at 250 degrees Celsius. |

| Electrical insulation | High heat resistance to reduce electrical insulation. |

| Water resistance | The arrangement of methyl groups in molecules makes them hydrophobic, and therefore the film has little water absorption. In addition, even if water is absorbed, it will be released quickly and restored to its original state. |

| Weather resistance | Difficult to produce free radical reaction and oxidation reaction caused by ultraviolet radiation, so it has excellent weather ability. |

| Mechanical strength | Small Intermolecular attraction and low effective crosslinking density to weaken the general mechanical strength (bending, tensile, impact, scratch resistance, etc.) |

Typical silicone resin -- Methyl MQ silicone resin

Silicone MQ resin is a relatively unique structure of the silicone resin with a silicone compound containing tetrafunctional siloxane chain (SiO4 / 2, Q) and monofunctional siloxane chain links (R3SiO1 / 2, M), which is subjected to co-hydrolysis-polycondensation reaction to form a three-dimensional spherical structure of silicone grease.

M Unit

Used as an end-blocker in the formation of siloxane chains or to terminate resin growth.

Q Unit

Used to form Silicone gel by condensation of hydroxyl groups under acidic or basic conditions

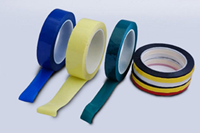

Applications -- Silicone Pressure Sensitive Adhesive

MQ silicone resin is a kind of silicone resin, which has a unique structure and excellent performance, primarily as a surface treatment agent and the silicone pressure-sensitive adhesive tackifiers, reinforcing fillers for silicone rubber, silicone antifoam agents, anti-blocking agents, heat resistant coatings, mold release agents, water repellent for construction and textile, etc.

Silicone pressure-sensitive adhesive is a special adhesive made of silicone MQ resin, silicone rubber, catalyst, crosslinking agent and other additives. Silicone MQ resin mainly has the thickening reinforcing effect. A hydroxyl group or a vinyl resin in silicone MQ resin respectively synthesized with a hydroxyl group or the silicone rubber under the effect of the catalyst to produce the Silicone pressure-sensitive adhesive.

The molecular quality of MQ resins has a great impact on the adhesion of pressure-sensitive adhesive properties. The change of molecular makes the viscosity and cohesive strength of the pressure-sensitive adhesive change. When the molecular weight is high, the pressure-sensitive adhesives have high cohesive strength and good viscosity; while the molecular weight is low, the bulk viscosity is low, and the interfacial adhesion can be improved, but the polymer has low cohesive strength and is liable to cause cohesive failure during peeling.

XJY Silicones -- first choice of silicone resins supplier

XJY Silicones manufacture silicone methyl MQ resins, vinyl resins for 35 years, with the combinations of an experienced R&D team and professional sales services. According to the customer's manufacturing process, operation requirements, curing conditions, equipment and material performance requirements, we can recommend how to select more appropriate products, and also provide customized products and solutions according to the customer's situation.