As environmental awareness increases, silicone release agents with low VOC (volatile organic compound) content are becoming increasingly popular in the marketplace. In the future, silicone release agents will pay more attention to the use of biodegradable or low-toxicity components to reduce the impact on the environment. At the same time, with the advancement of new material technology, silicone release agents will also be developed with more multi-functional properties, such as improved abrasion resistance and high temperature resistance, in order to adapt to the needs of more special application scenarios. What are the new applications for silicone mold release agents?

Silicone release agent is a kind of high-performance release agent made of silicone as raw material, which has the advantages of good chemical stability, high temperature resistance, good release effect, low surface tension, and low production cost. With the continuous progress of science and technology and the increasing complexity of industrial production, silicone mold release agent applications continue to expand, from the traditional rubber products, plastic products production, and gradually extended to automotive manufacturing, aerospace, electronic components, new energy,y and other fields, showing broad market prospects.

There are six aspects to introducing silicone mold release agent?

- What is a silicone mold release agent?

- How are silicone mold release agents classified?

- What are the characteristics of silicone mold release agents?

- What are the applications of silicone mold release agents?

- What is the future of silicone mold release agents?

- How to make silicone mold release agent

1. What is a silicone mold release agent?

Silicone-modified mold release agents a widely used in plastics, rubber, ceramics, and other polymer materials molding process of auxiliary materials. It effectively reduces the friction coefficient between the mold and the material by forming a protective film on the surface of the mold to achieve the purpose of mold release. Silicone-modified mold release agent has excellent high-temperature corrosion resistance, wear resistance, easy to clean and other characteristics, can significantly improve production efficiency and product quality.

2. How are silicone mold release agents classified?

According to the product form, silicone modified mold release agents can be divided into liquid, past,e and solid three categories. Liquid mold release agents dominate the market because of their ease of use, environmental protection and other characteristics. Paste mold release agent is mainly used for complex mold release, with better adhesion and lubrication. Solid release agents are mainly used forthe molding process of powder materials, with the advantages of environmental protection and economy.

The classification of silicone-modified release agents also includes general-purpose, special, and environmentally friendly. General-purpose mold release agents are suitable for most molding occasions with a better cost-effective. Special type release agents are designed for specific materials or process requirements, such as high and low temperature release agents, acid and alkali resistant release agents. Environmentally friendly mold release agents focus on environmental performance, reduce the pollution of the environment. A new type of environmentally friendly mold release agent, for example, its VOC content lower than the national environmental standards, has been applied in a number of automotive parts manufacturing enterprises, to the customer's unanimous praise. With the improvement of environmental awareness, it is expected that the market demand for environmentally friendly mold release agents will continue to grow in the future.

3. What are the characteristics of silicone mold release agents?

(1) Low surface energy

The surface energy of silicone materials is extremely low, usually between 18-22 dynes/cm. This low surface energy allows the release agent to form a smooth film on the mold surface, which can effectively reduce the adhesion between the mold and the molding material.

The release process is smoother, the product is easier to detach from the mold, and the surface quality is higher. It can release mold rubbers from cured rubber molds.

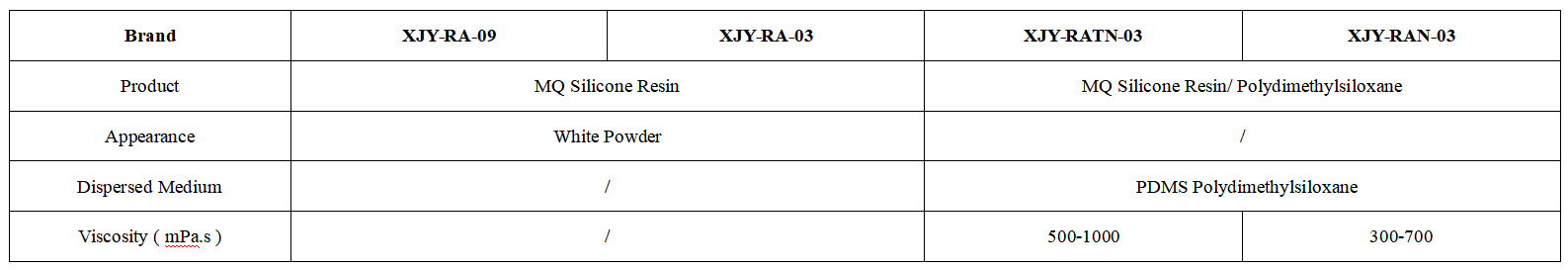

XJY-RA/XJY-RAN MQ Silicone Resin is a polymerization of tetrafunctional silicon (Q) and monofunctional methyl silicon (M) in the field of silicone high-temperature, semi-permanent, and permanent mold release agents. Silicone mold release agents are specially formulated to be resistant to high and low temperatures, have low surface tension, and are non-corrosive to metals. Adding silicone resin (5-15%) can significantly improve the strength of the silicone oil film, in the field of high-temperature casting and other areas of good application.

(2) High temperature resistance

The main chain of silicone mold release agent consists of silicone - oxygen bond, its bond energy is high, so it has excellent high temperature resistance. Usually, it can work stably under the high-temperature environment of 200℃-300℃.

Applicable to a variety of high-temperature molding processes, such as die-casting, injection molding, etc.,it will not decompose or fail due to high temperature.

(3) Chemical stability

Silicone mold release agent has good chemical stability, not easy to react with other chemicals.

In a variety of chemical environments can remain stable, will not have an adverse effect on the silicone rubber molding material or mold.

(4) Non-toxic and odorless

Silicone mold release agent is non-toxic and tasteless under normal use conditions, even in high temperature decomposition, its decomposition products are relatively safe.

It meets the requirements of environmental protection and health and is suitable for food packaging, medical equipment, liquid plastic products, and other fields with high safety requirements.

(5) Good lubrication

Silicone mold release agent has good lubricity, can effectively reduce the friction between the mold and molding materials, such as smooth on liquid plastics.

Reduce the friction in the demolding process, reduce mold wear, and prolong the service life of the mold.

(6) Non-migration

Part of the silicone mold release agent has non-migration; that is, it will not migrate from the mold surface to the molding material inside.

This ensures that the performance of the molding material is not affected while maintaining the long-term effectiveness of the release agent.

(7) Easy to apply and clean

Silicone mold release agents can be coated in a variety of ways, such as spraying, brushing, dipping, etc., and the film layer formed after coating is uniform.

Easy to use, can quickly cover the mold surface, while easy to clean after the mold release, expand production mold.

(8) Good compatibility

Silicone mold release agent has good compatibility with a variety of materials, will not cause corrosion or contamination of the mold or molding materials.

It is suitable for molding processing of many materials.

(9) Long service life

In particular, non-migratory silicone mold release agents show a super long service life due to their high heat resistance and stable film layer for properly prepared models.

It reduces the frequency of use and the replacement cost of the mold release agent.

(10) Environmental friendliness

Silicone mold release agents have less impact on the environment in the production and use process, in line with environmental requirements. Help enterprises to meet the requirements of environmental regulations, reduce environmental pollution.

4. What are the applications of silicone mold release agents?

4.1 Automobile manufacturing field

(1) Aluminum alloy die casting:

automotive manufacturing, aluminum alloy die casting materials production on the mold release agent requirements are extremely high. Silicone mold release spray can effectively reduce the adhesion between aluminum alloys and molds while maintaining stability at high temperatures. The silicone mold release agent product portfolio launched by Wacker Chemie not only improves the yield of mold release products but also significantly improves the temperature resistance, adapting to extreme high-temperature environments ranging from 300℃ to 400℃.

(2) Integrated die-casting:

The integrated die-casting process for new-energy vehicles places higher demands on mold release agents. Silicone mold release agents excel in this field, and their products can significantly improve production efficiency while reducing carbon buildup and extending the service life of mold release agents in mold making.

4.2 Aerospace

High-performance fiber composites molding: aerospace engineering in the use of high-performance fiber composites on the mold release agent requirements are extremely demanding, need to meet the high temperature, non-migration, high precision molding of parts, mold peeling force and other conditions. Special composite silicone resin is the basis of the polymer silicone mold release agent. Coating leveling is good; the coating film can be repeatedly used after curing at high temperatures and continues to maintain high-temperature resistance and non-migration of reliable mold release performance.

4.3 Electronic components

Dip coating anti-adhesion isolation: electronic components in the epoxy resin and other liquid resin impregnation encapsulation process, often encountered in the resin adherence to the metal lead is difficult to remove the problem. The use of low surface energy silicone polymers with a high crosslinking degree of curing agent components of efficient dip coating anti-adhesive isolation agent can form a solid layer of anti-adhesive isolation layer on the metal leads to ensure that electronic components are encapsulated tight and full and the leads do not stain the resin.

4.4 New energy field

Wind turbine blade production: Wind turbine blades are usually made of composite materials. A silicone mold release agent in this field with excellent performance can effectively solve the problem of composite material mold release, improve production efficiency.

4.5 Construction engineering field

Concrete component mold release: A silicone mold release agent has been widely used in the production of concrete components. Its good mold release performance can ensure the surface quality of concrete components while reducing mold wear.

5. What is the future of silicone mold release agents?

(1) High-performance product development:

As the field of application continues to expand, the performance requirements for silicone mold release agents are getting higher and higher. For example, Wacker Chemie has developed products with higher temperature resistance and better lubrication properties through formulation optimization.

(2) Environmentally friendly products:

Against the backdrop of increasingly stringent environmental protection policies, the development of solvent-free, water-based silicone release agents has become an important development direction for the industry.

(3) Market demand growth:

With automotive manufacturing, aerospace, new energy, and other fields of high-performance release agent demand continuing to increase, the silicone mold release agent market size is expected to expand further.

(4) Technological innovation:

In the future, the development of silicone mold release agents will be more dependent on technological innovation, including the development of new silicone polymers, improved formulations, and production processes.

6. How to make silicone mold release agent?

Silicone mold release aerosol spray has shown strong application potential in many fields due to its excellent performance. With the continuous progress of technology and market demand continuing to grow, silicone mold release agents will certainly play a more important role in the future of industrial production. How to improve the competitiveness of products?

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, more than 15 related patents and technical support, silicone raw material products to meet the needs of the release agent field, support for the provision of diversified customized solutions.