With the rapid development of modern industry and military and other industries, people on the use of metal materials performance requirements are increasingly high, not only need to operate at higher temperatures and more demanding corrosive environments, but also has to have impact resistance, mechanical strength, and wear-resistant and other properties, the ordinary organic coatings has been difficult to play a role in the protection of metal materials, the development of more excellent performance of high-temperature-resistant organic coatings is becoming more and more urgent! The development of more excellent performance of high-temperature resistant organic coatings is becoming more and more urgent, which is more common to the development of high-temperature resistant silicone coatings.

Silicone resin synthesis methods, including organochlorosilanes as raw materials, the use of hydrolysis condensation method for the synthesis of methyl phenyl silicone resin method has been concerned about the method of raw materials from the direct method of production, raw materials are easy to obtain, large yield, low cost. Silicone resin, as a film-forming material for coatings, is a key factor in the performance of coatings, and its unique thermal stability and excellent heat resistance as well as oxidative stability make silicone resin widely used in coatings and other fields.

The application of methyl phenyl silicone resin is introduced in the following five points:

- What is methyl phenyl silicone resin?

- What are the properties of methyl phenyl silicone resin?

- How to use methyl phenyl silicone resin?

- What are the fields of application of methyl phenyl silicone resin?

- How to choose methyl phenyl silicone resin?

1. What is methyl phenyl silicone resin?

Methyl phenyl silicone resin(contains methyl and phenyl groups) is significantly better than methyl silicone resin in mechanical properties, thermoelasticity, adhesion, gloss and compatibility with organic and inorganic fillers due to the introduction of phenyl silicone chain, which can be used as high temperature insulating varnish, high temperature adhesive, high temperature molding encapsulant, high temperature coating, ablative material, trapezoidal polymers, and micropowder of silicone resin, and it is one of the most widely used varieties of silicone resins in terms of usage and application. It is one of the most widely used and applied varieties of silicone resin.

2. What are the characteristics of methyl phenyl silicone resin?

Methyl silicone resin is characterized by strong aging resistance, good UV resistance, and no yellowing in long-term use. The properties of methyl phenyl silicone resin include the following.

Methyl phenyl silicone resin is a silicone resin with methyl and phenyl substituents and has the following key features:

(1) Thermal properties

High temperature resistance: Methyl phenyl silicone resin is able to maintain stability in a high temperature environment, not easy to flow or decomposition. Its continuous temperature resistance can be up to 650 ℃, at 300 ℃, when used for a long time, adhesion, impact resistance, and flexibility performance is still maintained well.

Thermal stability: good thermal stability at high temperatures, not easy to thermal decomposition or deterioration.

(2) Chemical properties

Chemical corrosion resistance: Good chemical corrosion resistance, able to resist the erosion of acids, alkalis, and other chemical substances.

Oxidation resistance: Excellent oxidation resistance, able to maintain performance for a long time in a high-temperature environment.

(3) Electrical properties

Electrical insulation properties: Excellent electrical insulation properties, dielectric strength >30 kV/mm, volume resistivity >1E15 ohm-cm, suitable for electrical insulation materials.

(4) Mechanical properties

Good adhesion: It can be combined well with a variety of substrates to enhance the adhesion of coatings, adhesives, and so on.

Excellent mechanical properties: due to the introduction of phenyl silicone oxygen chain, it is significantly better than methyl silicone resin in terms of mechanical properties, thermal elasticity, and adhesion.

(5) Optical properties

Glossiness: It has good glossiness.

UV resistance: good UV resistance, no yellowing in long-term use.

(6) Surface properties

Low surface energy: It has low surface energy and hydrophobicity, which makes it excellent in anti-corrosion and anti-pollution.

Weathering resistance: It has good weathering resistance and can maintain its effectiveness for a longer period of time under harsh external environmental conditions.

(7) Other properties

Compatibility with fillers: Good compatibility with organic and inorganic fillers.

Solubility: usually colorless or light yellow transparent liquid, soluble in toluene, xylene, benzene, and other solvents.

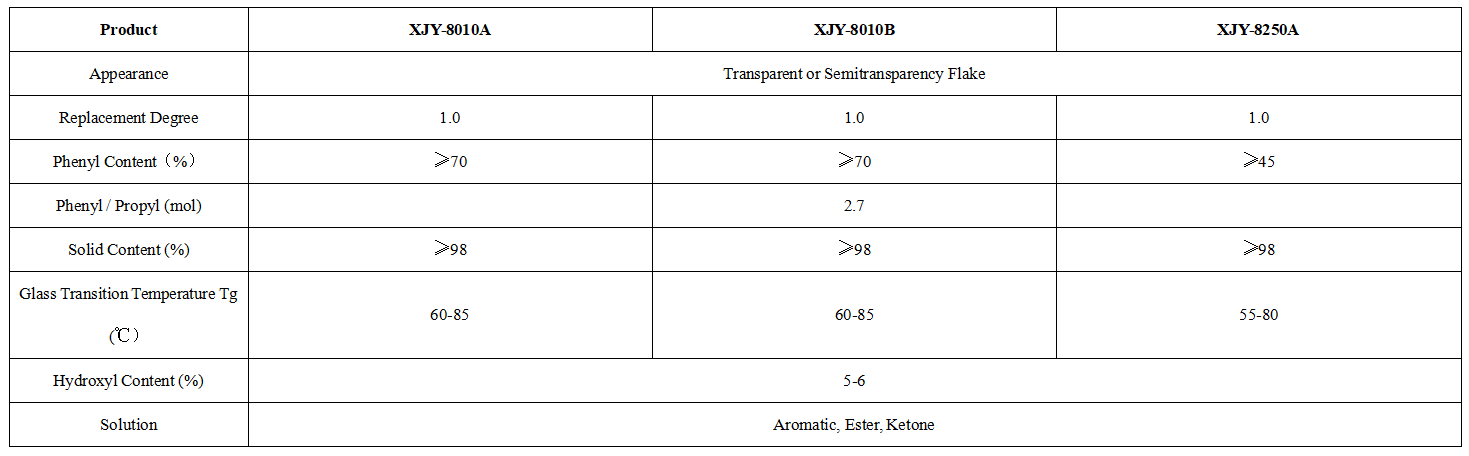

XJY-8010A/B/XJY-83350 Flake Silicone Resin

This single component can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200°C or even higher temperatures and can be used to prepare various heat-resistant coatings with heat-resistant insulation grades up to class H. Silicone resin(contains methyl groups) has excellent weathering resistance, and ultraviolet light resistance and can be used in powder coatings and liquid coatings. Silicone resins have excellent weathering resistance and provide all-around protection for equipment. Silicone resins have excellent weather resistance and good adhesion. Silicone thin layers also have excellent weathering, ozone resistance, arc resistance, hydrophobic moisture resistance, salt spray resistance, mold resistance, and other properties.

3. How to use methyl phenyl silicone resin?

(1) High temperature resistant coatings

Methyl phenyl silicone resin-based high-temperature coatings belong to the technical field of organic coating preparation. Methyl phenyl silicone resin is used as the base material, and the resin is made by hydrolyzing methyl trichlorosilane, dimethyl dichlorosilane, and methyl phenyl dichlorosilane as the hydrolyzed raw materials through hydrolysis, condensation, and other processes. The process is simple to produce, the resin yield is high, and the pure resin itself has good resistance to high and low temperatures; the pigment used in the coating is titanium dioxide, the filler is mica powder, talcum powder, low melting point glass powder, hollow glass microspheres, and the additives are organobentonite, KH-550, and the solvent is xylene. The organosilicon high-temperature resistant coating prepared by this invention is coated on the surface of the substrate, with fast drying speed at room temperature, tough coating film, high mechanical strength, and impact strength of more than 50 kg㎝. The coating can resist 1000℃ high temperature for a long time, and the salt spray resistance time is long.

(2) Silicone adhesive

Methyl phenyl silicone resin can be used to prepare room temperature curing silicone adhesive that can resist 1500℃ ablation. It is to solve the existing organic silicone adhesive ablation-resistant low temperature and room temperature curing difficult problem. Methods: first, pretreatment of methyl phenyl silicone resin; second, pretreatment of carbon fibers, get filler A; third, graphite, silicon carbide, zirconium diboride, nickel, tantalum oxide, hafnium diboride and niobium boride for ball milling, get filler B; fourth, after treatment of methyl phenyl silicone resin, filler A, filler B, ethyl orthosilicate and dibutyldiglycolinate tin is mixed at room temperature curing, that is complete. Organic silicone adhesive in this invention, cured at room temperature, can withstand 1500 ℃ ablation, practical applications now with now, no storage curing risk; preparation process is simple, raw materials from a wide range of sources; adhesive can be ablated at 1500 ℃ for 300 seconds after the heat loss of no more than 1%, and there is a certain degree of flexibility after ablation.

(3) Conductive composite materials

Methyl phenyl silicone resin can be used to prepare graphene organosilicone resin conductive composite materials, belonging to the technical field of conductive materials. The graphene silicone resin conductive composite materials described in the present invention by graphene and methyl phenyl silicone resin added to the ball mill grinding and mixing homogeneously produced, the graphene and methyl phenyl silicone resin weight ratio of 1:20~500. The present invention makes the silicone resin from the insulating to become electrically conductive so that there is graphene's good electrical conductivity but also silicone resin's excellent weathering and heat resistance, while the present invention uses a specific silicone resin to produce a conductive material. The present invention employs a specific silicone resin, namely methyl phenyl silicone resin, and a specific ratio, which further improves weathering and heat resistance, is easy to cure, and can be used to prepare conductive coatings, conductive films, and other conductive materials. In addition, the graphene organosilicone resin conductive composite material of the present invention is simple to prepare, suitable for industrialized production, effectively saving energy consumption and reducing costs.

Methyl phenyl silicone resin containing a hydrogen group has the appearance of a transparent viscous liquid at room temperature. Mainly used in the manufacture of high-power high refractive LED with silicone encapsulation adhesive, optoelectronics, electronics and microelectronics industry, potting, sealing, adhesive and coating, high transmittance, high hardness lenses and other user-developed applications, the product cured film hardness, high refractive index, good light transmission, with strong solvent resistance, water resistance, and resistance to ablation and radiation, and at the same time, high temperature resistance, good performance, no viscosity and other advantages.

4. What are the applications of methyl phenyl silicone resin?

Methyl phenyl silicone resin is an organosilicon compound with excellent chemical stability and physical properties, so it is widely used in various fields. The following are some of the main applications of Methyl Phenyl Silicone Resin:

(1) Electronic materials

Methyl phenyl silicone resin has excellent insulating properties and high temperature resistance, so it is widely used in the field of electronic materials. For example, in the semiconductor manufacturing process, methyl phenyl silicone resin can be used as an encapsulation material for electronic components to protect them from the external environment.

(2) Adhesive field

Methyl phenyl silicone resin has good adhesive properties and can be used as an adhesive for various materials. For example, in the aerospace field, methyl phenyl silicone resin can be used as a structural adhesive for spacecraft to improve their strength and durability of spacecraft.

(3) Coating field

Methyl phenyl silicone resin can be used as a film-forming agent for various coatings to improve the adhesion and durability of coatings. For example, in automobile manufacturing, methyl phenyl silicone resin can be used as a film-forming agent for automobile coatings to improve the durability and appearance quality of automobiles.

5. How to choose Methyl Phenyl Silicone Resin?

The deepening application of Methyl Phenyl Silicone Resin in key industries such as electronics, construction, automotive, and new energy has pushed the market demand to grow steadily. The accelerated industrialization of emerging economies and the increased demand for environmentally friendly and sustainable materials provide new growth opportunities for the Methyl Phenyl Silicone Resin market (Canada and so on). How to improve the competitiveness of your product formulations? Please contact us.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of various fields and support the provision of diversified, customized solutions.

![]()