Silicone rubber as a medical material after decades of clinical applications, has been recognized by the medical community, the application is becoming more and more widespread, and many large companies and medical device manufacturers to medical silicone rubber as the main target of development. What are the advantages of medical silicone rubber?

Medical food-grade silicone rubber has good biocompatibility and is a non-irritant, non-toxic, and non-allergic reaction to human tissue. Secondly, medical silicone rubber is resistant to high temperatures, oxidation, and biological aging. In addition, it is characterized by softness, elasticity and high transparency, and has good processing performance, which can be made into various shapes of medical devices. Its physiological inertia so that its contact with human tissue and blood will not produce adverse reactions. These characteristics make medical-grade materials in the life sciences, medical devices, drugs, and other fields have wide and important applications, but there is still a huge potential to dig, with the development of life sciences and biomaterials research, it will make greater contributions to human society.

The following five aspects of the application of medical silicone rubber:

- What is medical silicone rubber?

- What are the characteristics of medical silicone rubber?

- Why choose silicone as a medical material?

- How about the application of silicone rubber?

- How to make medical silicone rubber performance better?

1. What is medical silicone rubber?

Silicone rubber used as medical materials has high-temperature resistance, oxidation resistance, hydrophobicity, flexibility, permeability, aging resistance, high transparency, physiological inertia, non-adhesion to human tissues and blood, good bio-adaptability, non-toxic, tasteless, non-carcinogenic and a series of excellent characteristics in compression molding and other molding ways.

Silicone rubber as a good performance of medical polymer materials, both in the rubber industry and in the medical field has attracted the attention of professionals. The reason is that, first of all, silicone rubber medical materials with high technological content, and high added value, the economic benefits are very substantial; secondly, the use of silicone rubber medical properties, not only solves a number of medical problems but also enables the patient to obtain satisfactory results; thirdly, the use of silicone rubber from a wide range of sources, to facilitate the production of silicone rubber products manufacturers and fine processing, has good social and economic benefits.

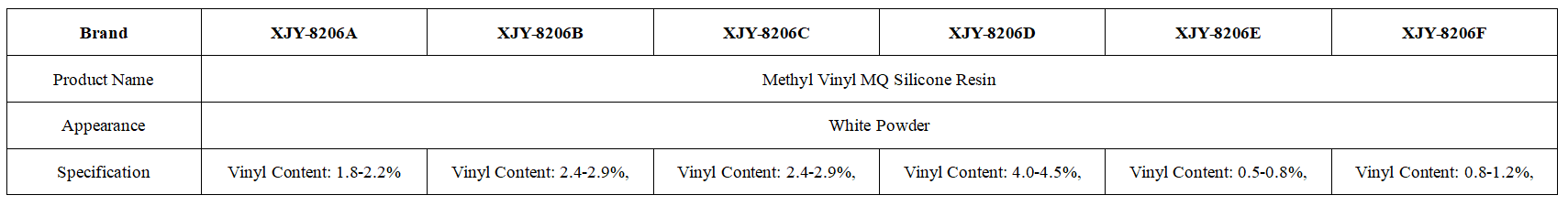

XJY-8206 vinyl methyl silicone resin

It is a condensate of tetrafunctional siloxane (Q) and monofunctional methyl silicone (M), silicone polymers and silicone compounds made of VMQ materials, with wide temperature resistance, abrasion resistance, weather resistance, resistance to compression deformation, resistance to ultraviolet radiation and other physical properties, and harmless to the human body, can be applied to the medical and food industries, can be made for liquid silicone rubber.

2. What are the characteristics of medical silicone rubber?

(1) Good biocompatibility, non-irritant, non-toxic, non-allergic reaction to human tissue.

(2) It has good physical and chemical properties, and body fluids and tissue contact process can maintain its original elasticity and softness, not be degraded.

(3) It can withstand high temperatures and can be sterilized. Convenient processing and molding, easy to process the sculpture shape, easy to use.

Medical silicone rubber is mainly in contact with the human body, in vivo implantable silicone rubber can be found everywhere in life, such as silicone rubber nose jobs, and prosthetic products, why use medical grade silicone rubber? Because the human body directly and a part of direct contact, in order to prevent the risk of infection.

3. Why choose silicone as a medical material?

The unique chemical structure of silicone compounds determines their excellent chemical properties.

3.1 Stability

Due to the bond energy of the Si-O bond being large, its fracture requires more energy, making it relative to the C-C chain of organic polymers more stable in all aspects; at the same time, due to the rotational energy barrier of the Si-O bond is small, the polysiloxane chain is extremely flexible, so that under a wide range of conditions can maintain free movement. Its stability is manifested in a number of ways: first, silicone materials in a wider range of temperatures to maintain the stability of performance; second, in the sustained applied energy field can maintain the performance of a relatively stable, such as UV, heat, high-energy rays, etc. Therefore, some of the environmentally harsh (such as high temperatures, and high radiation) of special occasions have a wide range of applications; and then, the silicone material in the natural environment does not easy to be oxidize, and therefore has a better weather ability and anti-aging properties. Therefore, in the medical field, silicone materials have the ability to resist sterilization, anti-aging, and many other advantages, in some of the need for long-term, repeated use of medical devices are widely used. In addition, the side chain of polysiloxane, if there are energy-absorbing functional groups, such as phenyl, etc., can further improve the stability of silicone materials.

3.2 Surface properties and biocompatibility

The surface tension of silicone rubber is much lower than that of other materials. Therefore, silicone materials have excellent hydrophobicity, and it is also noteworthy that their hydrophobic properties are maintained relatively permanently and are not subject to change under the influence of polar substances. This is due to the small interaction forces of the methyl groups on the polysiloxane chains and the very flexible movement of the chain segments. At the same time, due to the reaction inertia of polysiloxane, it has no carcinogenicity, good anticoagulant and biocompatibility, and other characteristics, in contact with human tissue safety, not easy to be infected, fewer rejection reactions, and its performance is far superior to other materials It is based on these special surface properties and biocompatibility of silicone rubber, which has been used in large quantities to make the human body with the inside and outside of the catheter, intubation, artificial joints and so on.

3.3 Permeability

Rubber (PDMS) is the existing general-purpose polymer with the highest gas permeability of the material, which is due to its polymer has high degree of chain mobility and the rapid response to the dissolution of the permeable material caused by the PDMS Si-O-Si bond angle varies in the 130-160 ° between the molecular chain of PDMS is highly convoluted and was a helical structure, and the intermolecular forces are also very small, the gas and volatile organic compounds in the diffusion and migration of gas and volatile organic compounds in which is very easy, so the diffusion coefficient or permeability coefficient is much larger than other polymer materials. Therefore, the breathability of silicone materials gives it unique advantages in wound care, while feeling comfortable in contact with the skin.

4. What about silicone rubber applications?

Since 1960, silicone rubber has been increasingly used in the field of medical devices due to the aforementioned excellent properties it possesses, especially its excellent biocompatibility and biological inertness. According to the different types of medical device applications, medical silicone rubber can be divided into two categories: long-term implantation and short-term contact. Devices that have been implanted in the human body for more than 29 days are called long-term implantable, while short-term contact refers to devices that have been in contact with the human body for less than 29 days.

In the existing medical silicone rubber applications, short-term contact type medical devices, including human catheters, infusion tubes, laryngeal tubes, silicone binders, and lubricants, etc.; long-term implant-type medical products, including artificial breasts, artificial joints, facial implants, etc. ISO10993-1 standard and according to the contact time of the human body tissues of the short-term contact type of medical silicone rubber is further subdivided into the ultra-short-term contact type of contact time less than 24h). Time less than 24h) and longer-term contact type (contact time greater than 24h, less than 29 days) are two categories.

The different types of applications require that the material meets the appropriate biotoxicity tests. Silicone rubber materials can be widely used in various types of materials, at present, the largest amount of medical silicone rubber or in the regular contact type of medical devices.

(1) Fluid catheter

Fluid-conducting tubes are medical devices that are inserted into the human body to deliver drugs, diagnostic reagents, or body fluids through catheter insertion. According to the different uses, the shape and size of the medical catheter are very different, and generally can be divided into: cardiovascular catheter, nerve catheter, intravenous catheter, and urinary catheter. The materials used include silicone rubber, natural latex, polyvinyl chloride, polytetrafluoroethylene, and polyurethane. But silicone materials because of their unique properties, become one of these medical devices of choice. This is because: silicone rubber material is soft to the touch, has good elasticity, and has higher strength than natural latex, so the same outer diameter when the volume is larger, improves the efficiency of delivery; In addition, injection molding silicone rubber is also used to make infusion tubes to transport a variety of liquid medicine.

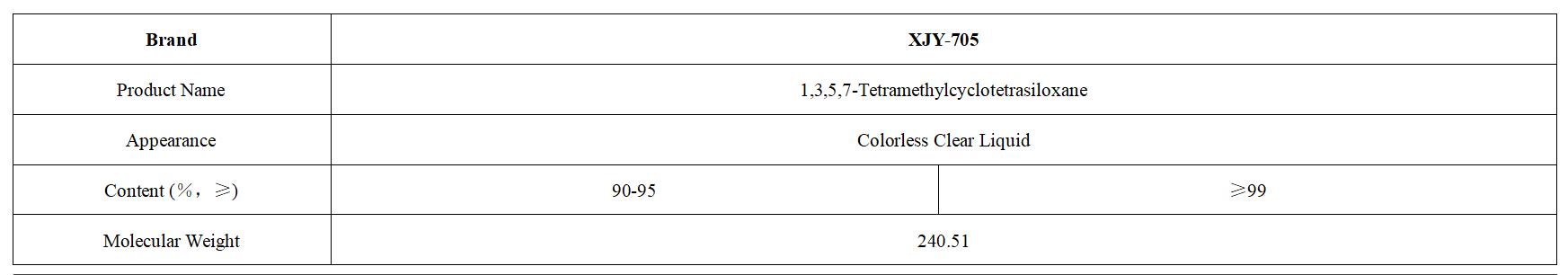

XJY-705 1,3,5,7-Tetramethylcyclotetrasiloxane(D4H)

It is a reactive siloxane containing Si-H bond, can be an unsaturated olefin addition reaction, and can be used for the synthesis of room-temperature vulcanization of silicone rubber.

(2) Silicone adhesives

Silicone adhesives used in the medical field can be divided into two types: silicone pressure-sensitive adhesive and room-temperature vulcanized silicone rubber. Among them, silicone pressure-sensitive adhesive is easy to remove, not easy to get infected after a long time of use, breathable and can be used as an excellent wound care material, and is also widely used in fields such as pain-relieving tape, sports tape and so on. Room temperature vulcanized silicone rubber is mainly used as an adhesive in contact with the human body to fix other silicone material parts can be maintained for a long time with stable performance, not easy to be infected.

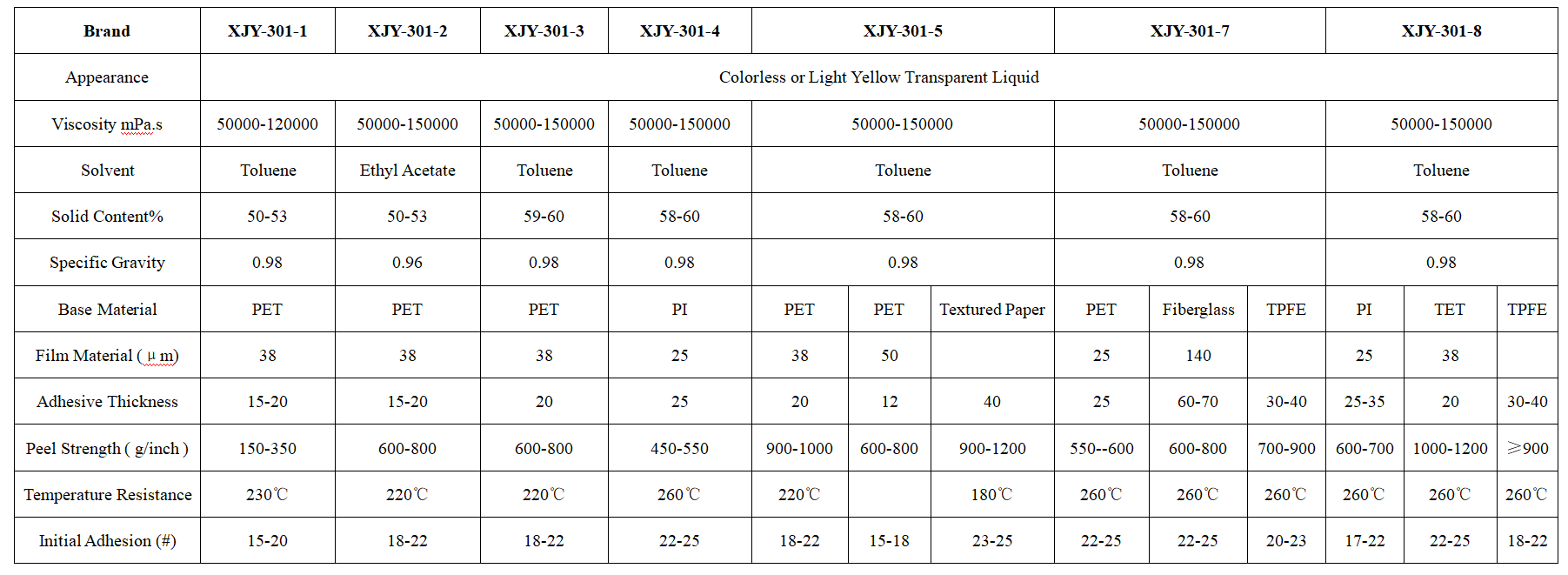

XJY 301 Silicone Pressure Sensitive Adhesive (SPSA)

It is a colorless transparent viscous liquid with moderate peeling force, suitable for wrinkled paper, PET film, medical tape, and other adhesive tapes, the adhesive has a moderate peeling force, non-toxic, environmentally friendly, skin-friendly, strong aging resistance, adhesion, and other characteristics.

(3) Mask

The laryngeal mask requires easy insertion into the human larynx, comfortable contact with oral tissues; and can be repeatedly used to maintain cleanliness; the mask is transparent and easy to observe. The silicone rubber feels soft, and breathable, making it comfortable to contact with the human body; biocompatibility, so that the human body is not easy to be infected, keeps clean: good stability, can be repeatedly disinfected without aging: transparent appearance, easy to meet the design of a variety of shapes. In addition, silicone rubber can be coated outside the silicone coating to reduce the friction coefficient of silicone rubber material in the human body, so that the mask is easy to insert. Therefore, silicone rubber material can fully meet the design requirements of the mask.

5. How to make medical silicone rubber better performance?

Medical silicone rubber has excellent biocompatibility, non-irritation and non-toxicity to the human body. It is resistant to high temperatures and aging and can be repeatedly sterilized. Soft and elastic, it can adapt to human tissue activity. Good processing performance, can be made into a variety of medical device manufacturing. Its physiological inertia makes it safe and reliable for long-term use in the body and is an ideal medical material. How to improve the competitiveness of products?

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry(also producing medical-grade silicone

), and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of medical applications and provide diversified customized solutions for qualified industrial users.