Increasing demand for packaged and convenience foods is expected to have a positive impact on the market. Moreover, the expansion of the retail sector and the shift in consumer preference toward sustainable packaging are expected to drive market growth. How to apply MQ silicone resins in release papers?

MQ silicone(organic resins) has significant advantages when applied to release liners. It has excellent barrier properties that prevent adhesive substances from adhering to the release paper (non-reactive with other substances), resulting in a good release effect. Secondly, it has excellent heat resistance and low temperature resistance and can be used in the temperature range of -60℃ to 300℃, ensuring the stability of the release paper in different environments. In addition, MQ silicone resin has good weathering and uv radiation, which can extend the service life of the release paper. Finally, it also has a certain degree of adhesion so that the release coating can be firmly attached to the surface of the paper and is not easy to come off.

The following introduces the advantages of MQ silicone resin from seven points:

- What is release paper?

- Why choose silicone release agent?

- What is MQ silicone resin?

- What kinds of modifications are available for MQ silicone resin?

- How to apply MQ silicone resin in release paper?

- What is the prospect of silicone resin in the release paper market?

- How do you choose silicone MQ resin?

1. What is release paper?

Anti-adhesive liners are plastic or paper films that prevent sticky surfaces (mainly labels) from adhering prematurely. The substrate surface of the liner can be coated with PVC, polyethylene, PET, polyester, and other materials. Release liners are used for self-adhesive plastic sheets, pressure-sensitive tapes, and labels. The use of this type of liner makes the handling of objects easier. It is coated on both sides with silicone as a base for the anti-adhesive coating, which provides the proper anti-adhesive performance against the appropriate adhesive.

However, the use of release liners also generates waste that cannot be easily disposed of. Growing concerns over the disposal of the waste generated will hinder the growth of the market.

2. Why choose silicone release agents?

Silicone release agent has the advantages of good transparency, good stability, high and low temperature resistance, adjustable release force, etc., in the pet, pe, pi and other film substrates can be coated to prepare a release protection film, widely used in functional films, touch industry and electronics industry. These industries in the specific application of the release protective film release force size needs are different, and the choice of silicone release agent is relatively small. In this context, the silicone release agent peel regulator came into being.

Silicone release agent with excellent performance, a wide range of applications, can be used for paper products, pressure-sensitive adhesive, self-adhesive labels, adhesive tapes, can also be used for synthetic leather products, synthetic fiber spinning and other production and molding and processing of polymer materials, food molding and processing, viscous substances such as packaging and other fields. With the continuous popularization and application of the current electronic display, used to do electronic display protective film release film dosage is also growing rapidly, which further led to the expansion of the application of silicone release agent and production growth. In the application of processing, silicone release agent, although generally accounted for a small proportion, such as the production of self-adhesive labels, the quality of the release agent coating only accounted for 0.2% of the total quality, but its role is more critical, and its performance has a direct impact on the final use of the product performance.

3. What is MQ resin?

MQ resin is a silicone resin with a unique structure, generated by the co-hydrolysis-condensation reaction of silicone compounds containing tetrafunctional siloxane links and monofunctional siloxane links (T units). Its structure is a double-layer dense sphere with a high-density caged SiO₂ core and a lower density R₃SiO₁/₂ layer in the outer shell.MQ resins have excellent heat resistance, weatherability, waterproofing, and adhesion and are widely used in a variety of fields.

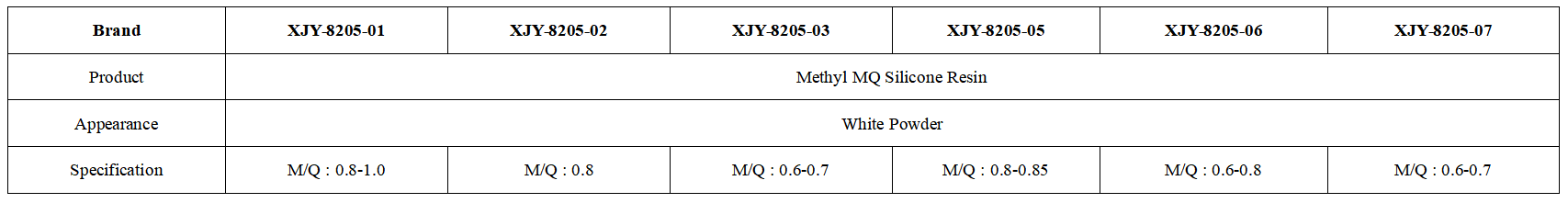

XJY-8205 MQ Resin (reaction product of sodium silicate with trimethylchlorosilane and isopropyl alcohol) is a product of the co-hydrolysis of tetraalkoxysilane (Q-unit) and trimethylalkoxysilane (M-unit) and contains methyl groups.

MQ resin is widely used in personal care, adhesives, defoamers, water repellents, etc. It has good mold release power in release agents for polyurethane processing.

XJY-8205M/M-02/M-03 Methyl MQ Silicone Resin toluene solution is also an important raw material for PSA(pressure-sensitive adhesives).

4. What kinds of modifications are available for MQ resins?

In order to further enhance the application effect of MQ resin in release paper, researchers have carried out various modifications:

4.1 Vinyl modification:

By controlling the vinyl content, the release force and durability of MQ resin can be adjusted. For example, modified vinyl MQ resins with a vinyl content of 0.3% to 2% have been used in release papers with remarkable results.

(1) After the vinyl MQ resin is added to the silicone coating as a functional additive, there is a great improvement in the thermosetting, adhesion, and peeling force of the coating.

(2) The addition of vinyl MO resin requires a shorter reaction time and higher curing efficiency than without the addition, and the curing efficiency reaches the highest when the vinyl content is 2%.

(3) The slight desilication time and severe desilication time of the vinyl MO resin are greatly improved compared to those without vinyl MQ resin. When the vinyl content is 1%, it has the best effect on the improvement of desilication performance, with the slight desilication time increased by 45.45% and the severe desilication time increased by 53.54%.

(4) Compared with those without vinyl MO resin, the peeling force at room temperature for 20 min, at room temperature for 24h, and at aging for 24h are greatly improved. When the vinyl content is 2%, the regulation effect is the most obvious, the peeling force at room temperature 20min increased by 41.42%, the peeling force at room temperature 24h increased by 35.34%, and the peeling force at aging 24h increased by 31.90%.

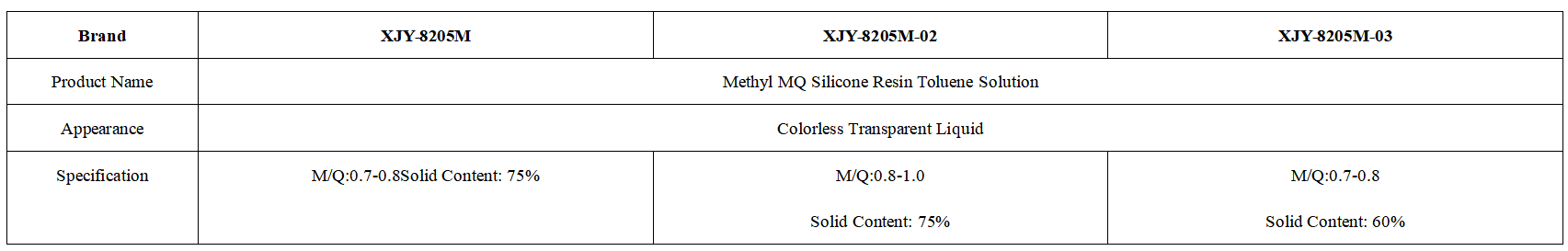

XJY-8206 Vinyl Methyl VMQ Silicone Resin

XJY-8206 Vinyl Methyl Silicone Resin is a condensation of tetrafunctional siloxane (Q) and monofunctional methyl siloxane (M), its molar mass is generally 2500-5000g/mol, the ratio of the chain length of M and Q in the molecular structure, as well as the structural properties of M to determine the application areas of the resin.

Silicone polymers and silicone compounds made from VMQ materials have physical properties such as wide temperature resistance, abrasion resistance, weathering resistance, compression deformation resistance, and ultraviolet radiation resistance and are harmless to the human body and can be used in the automotive industry, medical and food industry.

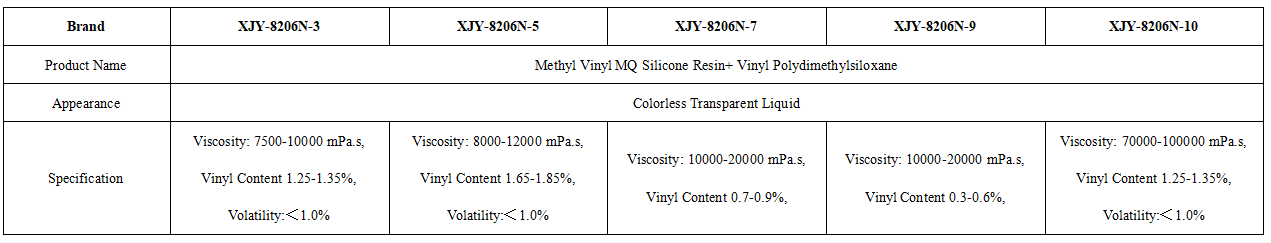

XJY-8206N VMQ Silicone Resin is a colorless transparent liquid resin composed of vinyl MQ silicone resin and vinyl dimethicone, which can be used for LSR liquid molding silicone rubber, LED encapsulation adhesive, and other two-component molding adhesives.

4.2 Hexamethyldisilazane treatment:

Adding hexamethyldisilazane in the synthesis process of MQ resin can improve the stability and release properties of the resin.

4.3 Composite Modification:

Compounding MQ resin with other materials (such as polyurethane acrylate) can synthesize the advantages of a variety of materials to further enhance the performance of the release paper.

5. How to apply MQ silicone resin in release paper?

5.1 Performance enhancement of release paper coating

Release paper is a kind of paper with a special surface treatment, mainly used to prevent adhesives, coatings, and other substances from sticking to the paper. The application of MQ resin in the release paper coating is mainly reflected in the following aspects:

(1) Enhance the release performance: MQ resin has excellent isolation properties and can significantly improve the release effect of the release paper. For example, vinyl MQ resin added to the release agent can improve the durability of the release paper and release force stability.

(2) Improve the durability of the coating: MQ resin's heat resistance and aging resistance means it can still maintain a good release effect. Research shows that the addition of vinyl content of 2% of the MQ resin can significantly improve the peeling force and durability of the release paper.

(3) Adjustment of peeling force: By controlling the vinyl content and molecular weight of MQ resin, the peeling force of the release paper can be adjusted. For example, modified vinyl MQ resin with vinyl content of 0.5%~1.2% can be used to prepare high peeling force release paper.

5.2 UV curing release paper coating

UV curing technology has gradually gained attention in the field of release paper coating due to its high efficiency and environmental protection. The application of MQ resin in UV curing release paper coating is mainly reflected in the following aspects:

(1) Improvement of coating adhesion: MQ resin can enhance the adhesion of UV-curable coating and substrate (such as Gramoxone paper). Experiments have shown that after vinyl MQ resin is compounded with polyurethane acrylate, the water and solvent resistance of the coating is significantly improved.

(2) Optimization of curing performance: The addition of MQ resin can improve the curing speed and film formation of UV-curable coatings. For example, a release agent with modified vinyl MQ resin exhibits better coatability and film-forming properties during the curing process.

5.3 Market applications of release liners

Release liners are widely used in tapes, labels, electronic components, composites, etc. The addition of MQ resin can significantly improve the performance of release liners to meet the needs of different industries:

(1) Tape industry: In the production of adhesive tapes, release paper is used to prevent adhesive from sticking to the paper, and MQ resin can improve the release force and durability of release paper, thus extending the service life of the tape.

(2) Electronics industry: In the production of electronic components, release paper is used to protect the surface of the components, and the high temperature and chemical resistance of MQ resin make it an ideal release material.

(3) Composite materials: In the production of composite materials, release paper is used to prevent the material from adhering to the mold, and the high release force and durability of MQ resin ensures the surface quality of composite materials.

6. What are the prospects of silicone resin in the release paper market?

With the increasing demand for high-performance release liners, MQ resins have a promising future in the release liner field. The future development direction includes:

(1) Development of high-performance release papers: By further optimizing the performance of MQ resins, release papers with higher peeling force and greater durability are developed.

(2) Environmentally friendly release paper: With the improvement of environmental protection requirements, the development of solvent-free, low-volatile organic compounds (VOC) of the release paper will become the trend.

(3) Multi-functional release paper: Combining the various excellent properties of MQ resin, we will develop multi-functional release paper with waterproof, moisture-proof, and high-temperature resistance.

7. How to make silicone MQ resin better?

MQ resin has shown a broad application prospect in the field of release paper due to its excellent release performance, heat resistance, weather resistance and adhesion. Through modification and optimization, MQ resins can further enhance the performance of release papers to meet the needs of different industries. In the future, with the continuous progress of technology, the application of MQ resin in release paper will be more extensive. How to improve the competitiveness of products?

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone pressure-sensitive adhesive field and provide diversified, customized solutions for qualified industrial users.