With the rapid development of new energy vehicles, smart wearable devices, 5G communications, and other emerging industries, the demand for conductive silicone rubber continues to grow. In the field of new energy vehicles, conductive silicone rubber is in particular demand as a material for battery connectors, seals, and other key components. In addition, the upgrading of consumer electronics products and the development of the medical equipment industry have also contributed to the expanding application of conductive silicone rubber. Why choose conductive silicone rubber?

Conductive silicone rubber has excellent conductive properties, can maintain the good elasticity and flexibility of silicone rubber on the basis of stable electrical conduction. Secondly, conductive silicone rubber inherits the high and low temperature resistance characteristics of ordinary silicone rubber and can maintain stable performance in the temperature range of -60℃ to 250℃, which enables it to adapt to a variety of extreme environmental conditions. In addition, conductive silicone rubber has good weathering and anti-aging properties and can resist the erosion of UV rays, ozone, and other environmental factors, thus extending its service life. In the electronic and electrical fields, its excellent electrical insulation properties make it an ideal insulating material, able to maintain a stable insulation effect in high voltage and humid environments. Conductive silicone rubber also has good biocompatibility, in line with the FDA and other international certification standards.

There are six aspects to introducing silicone rubber:

- What is conductive silicone rubber?

- What is the mechanism of conductive silicone rubber?

- What are the properties of conductive silicone rubber?

- How to classify conductive silicone rubber?

- What are the applications of conductive silicone rubber?

- How can conductive silicone rubber perform better?

1. What is conductive silicone rubber?

Thermally conductive silicone rubber material is a typical polymer composite material, its thermal conductivity is mainly determined by the type of thermally conductive filler and the distribution of thermally conductive filler in the silicone rubber matrix, thermally conductive filler is divided into metal filler and inorganic non-metallic filler, a variety of filler thermal conductivity mechanism is different, which determines the thermal conductivity effect or thermal conductivity of the difference.

Conductive silicone rubber is based on silicone rubber, adding conductive fillers, crosslinking agents and other matching vulcanization and become. Commonly used rubber for methyl vinyl silicone rubber, commonly used conductive fillers are acetylene carbon black, furnace method conductive carbon black, carbon fiber, graphite, copper powder, silver powder, aluminum powder, and zinc powder.

Compared with polyester resins and epoxy resin, polyurethane conductive silicon rubber has the advantage of small volume resistivity, low hardness, high and low temperature resistance, aging resistance, good processability, especially suitable for strong conductive properties, complex shapes, and fine structure requirements.

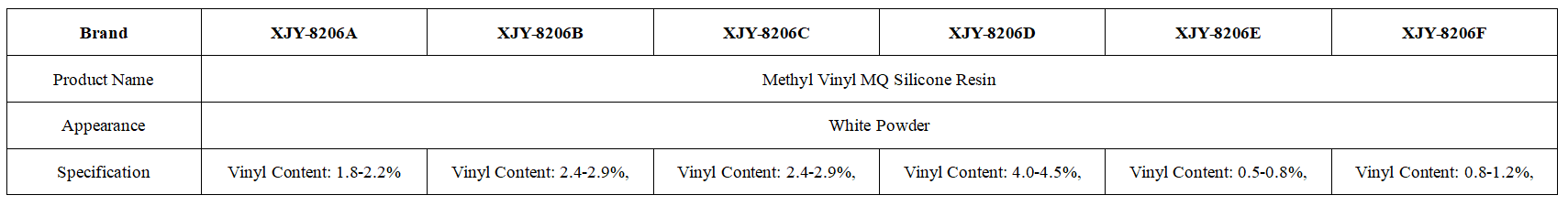

XJY-8206 Vinyl Methyl VMQ Silicone Resin

XJY-8206 Vinyl Methyl VMQ Silicone Resin is a condensation of tetrafunctional siloxane (Q) and monofunctional methyl siloxane (M). Silicone polymers and silicone compounds made from VMQ materials have physical properties such as wide temperature resistance, abrasion resistance, weather ability, compression deformation resistance, UV radiation resistance, etc., and are harmless to the human body, which can be used in the automotive industry, medical treatment, and food industry.

XJY-8206N VMQ Methyl Vinyl MQ Silicone Resin + Vinyl Dimethicone

XJY-8206N VMQ Silicone Resin (trimethyl vinyl siloxysilicate) is a colorless transparent liquid resin composed of vinyl MQ silicone resin (vinyl t structure fluids) and silicone vinyl dimethicone, which can be used as blend polymers or base polymers for LSR liquid molding silicone rubber, LED encapsulation adhesive, and other two-component molding adhesives.

2. What is the mechanism of conductive silicone rubber?

Silicone rubber is a good electrical insulator. Composite conductive silicone rubber conductive mechanism, there are generally two theories, the chained conductive pathway and the tunnel effect.

2.1 Chained conductive pathway: also known as overdiffusion theory

Chain-linking conductive pathway mechanism that the filler particles must be within a few nanometers of the distance close, so that the pressure difference can be generated, so that the filler particles of the π-electrons rely on the chain-linking transfer to move to achieve the current through. The dispersed state of filler particles in rubber to form the chain must have a certain amount of filler in order to appear strong conductive phenomena, and thus, the most important factor governing the electrical conductivity of rubber is the amount of filler, which is the most classical interpretation.

2.2 Tunneling effect: also known as tunneling theory

The chain-link conductive pathway is based on the premise that the filler must form a chain-link. However, an electron microscope to observe the stretched state of the rubber does not exist in the carbon black chain lock, but still conductive phenomenon, which is the tunnel effect.

When the conductive particles are not in contact with each other, there is a polymer barrier between the particles so that the conductive particles of free electrons are in the directional movement of the impediment. This obstruction can be regarded as a potential barrier with a certain potential energy.

For a microscopic particle, its energy is less than the energy of the potential barrier, it has the possibility of being rebounded; there is also the possibility of crossing the potential barrier. Microscopic particles go through the barrier phenomenon known as the penetration effect, also known as the tunnel effect.

3. What are the properties of conductive silicone rubber?

For conductive silicone rubber, the most important properties include the following points:

(1) Volume resistivity

Measure the conductive properties of conductive silicone rubber, as a conductor, conductive silicone rubber volume resistivity needs to be less than 10^3Ω-cm, the smaller the volume resistivity, the better the conductivity.

(2) Mechanical properties

Mechanical properties of conductive silicone rubber, mainly including tensile strength, elongation at break, tear strength, Shore hardness and compression permanent deformation.

(3) Aging resistance

Aging resistance is a very important performance of conductive silicone rubber, directly related to the stability and service life of the product.

(4) Shielding efficiency (dB)

Shielding effectiveness is a very important indicator of electromagnetic shielding materials, and conductivity-related, the stronger the conductivity, the higher the shielding effectiveness. Generally speaking, the shielding effectiveness of conductive silicone rubber is greater than 60dB.

4. How to classify conductive silicone rubber?

Conductive silicone products have molded and extruded these two common profiles.

(1) Molded conductive rubber

It can be made into a variety of thicknesses of the sheet, molded products, strip products, and die-cut flat liner.

(2) Extruded conductive silicone

It can be made into a variety of conventional cross-sections, continuous liner, rectangular, shapes, D-shaped, U-shaped, P-shaped, and a variety of thin-walled structures, but also customized according to user requirements of a variety of cross-sections.

5. What are the applications of conductive silicone rubber?

(1) Cold-shrinkable cable accessories and heat-shrinkable cable accessories, power tubes, stress relief rubber, and cable plugs

(2) Keyboards, keys, and other bottom contact with the conductor

(3) Photocopier roller

(4) Wire connection tube and voltage line insulators.

(5) Anti-static products:

Conductive silicone rubber, with its excellent conductivity, becomes the ideal material for manufacturing anti-static mats, gloves, and other products.

(6) Electromagnetic shielding and other fields:

When the volume resistance of conductive silicone is less than 10Ω-cm below, conductive silicone has electromagnetic shielding function. This feature makes conductive silicone in the need to seal and electromagnetic shielding occasions can play an important role. Conductive silicone volume resistivity is usually between 3 ~ 10Ω - cm, This feature allows it to effectively reduce electromagnetic interference, to protect electronic equipment from external electromagnetic interference, but also to prevent internal signal leakage, ensuring the normal operation of the equipment and data security. It can also be used for electronic and microwave waveguide systems such as chassis, cabinets, power transmission and transformation projects, and connector gaskets.

(7) Biomedical field:

Conductive silicone rubber conductivity and biocompatibility, for its application in the biomedical field, provides new possibilities. It can be used in the manufacture of biosensors, medical equipment, etc., to achieve the detection and monitoring of biological signals. At the same time, conductive silicone rubber can also be used for medical electronic equipment sealing and protection, to ensure the stable operation of the equipment. Line

(8) Electronic device sealing and protection:

Conductive silicone rubber plays an important role in the field of electronics, with its dual function to provide comprehensive protection for electronic devices: as a protective layer against the external environment on the erosion of electronic components and damage; through its conductive properties to maintain the integrity of the circuit pathway within the device. From tiny chips to complex circuit boards, conductive silicone rubber is widely used and important.

(9) Advanced touch screen technology:

Touch screen technology requires not only high-precision touch signal transmission but also to meet the requirements of durability and reliability. Conductive silicone rubber, with its excellent conductive properties,has become an important part of the touch screen technology. It is used as the conductive layer of the touch panel to ensure that the user's touch input can be accurately converted into electrical signals for a seamless user experience.

6. How can conductive silicone rubber perform better?

Silicone rubber has a number of advantages. First, it has a low volume resistivity and excellent conductivity. Secondly, its low hardness makes it easy to process and mold, making it suitable for manufacturing products with complex shapes and fine structures( such as respiratory masks). In addition, it is resistant to high and low temperatures (-70 to 200℃), aging resistance, and long service life. At the same time, the processing and manufacturing process performance is good, can be molded using a variety of processes. These characteristics make silicone systems widely used in electronics, medical applications, aerospace applications, and other specific applications. How to improve the competitiveness of products?

XJY Silicone is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R & D and manufacturing experience in the silicone industry, with more than 15 related patents and technical support, silicone raw material products to meet the needs of the field of silicone rubber, to support the provision of diversified customized solutions!

![]()