The silicone gel market has shown steady growth in recent years. The global silicone elastomer gel market size was estimated at USD 2.88 Billion in 2023 and is expected to reach USD 4.8 Billion by 2032, at a CAGR of around 5.82%. What are the application scenarios of silicone gels?

Silicone gel is a semi-solid polymer material formed by cross-linking of polysiloxanes, and its unique molecular structure gives it dynamic mechanical properties between liquid and solid. The alternating silicon-oxygen bonds (Si-O-Si) in the main chain provide excellent flexibility, while the organic groups in the side chains (e.g., methyl, phenyl) modulate their surface activity and compatibility through chemical modification. This flexibility in molecular design makes it one of the core materials in medicine, electronics, energy, and other fields.

There are four aspects to introducing silicone gel:

- Medical and healthcare fields

- Electronics and energy industries

- Industrial manufacturing

- Emerging application areas to expand

1. Medical and healthcare fields

(1) Wound care and tissue repair

In the field of wound dressings, silicone gels achieve a wet healing environment for wounds by regulating the oxygen and water vapor transmission rate (typically 2000-5000 g/m²/24h). Its low surface tension (approx. 21 mN/m) reduces adhesion to nascent granulation tissue, and clinical data show that patients using topical silicone gel dressings have a 40% reduction in the pain index of dressing changes. Medical-grade silicone gel also is non-toxic for sensitive skin. For diabetic foot ulcers and hypertrophic and keloid scars tissue, burn scars, and other chronic wounds, compound antibacterial ions of silicone gel sheeting can maintain 72 hours of continuous sterilization effect.

(2) Medical aesthetics and scar treatment

Based on the viscoelastic memory effect, the silicone gel membrane produces a continuous micro-pressure of about 15-25 mmHg on proliferative scars, which inhibits the excessive proliferation of fibroblasts. Silicone gel has good performance for hypertrophic scar formation. Transmission electron microscopy studies have shown a 60% increase in collagen fiber alignment and a 35% decrease in scar hardness and scar thickness after 6 months of use. The new light-curing silicone gel also enables 3D printing of customized scar patches with a thickness accuracy of ±0.1mm for hypertrophic scars. Silicone gel sheeting and pressure therapy can be combined to improve scar healing.

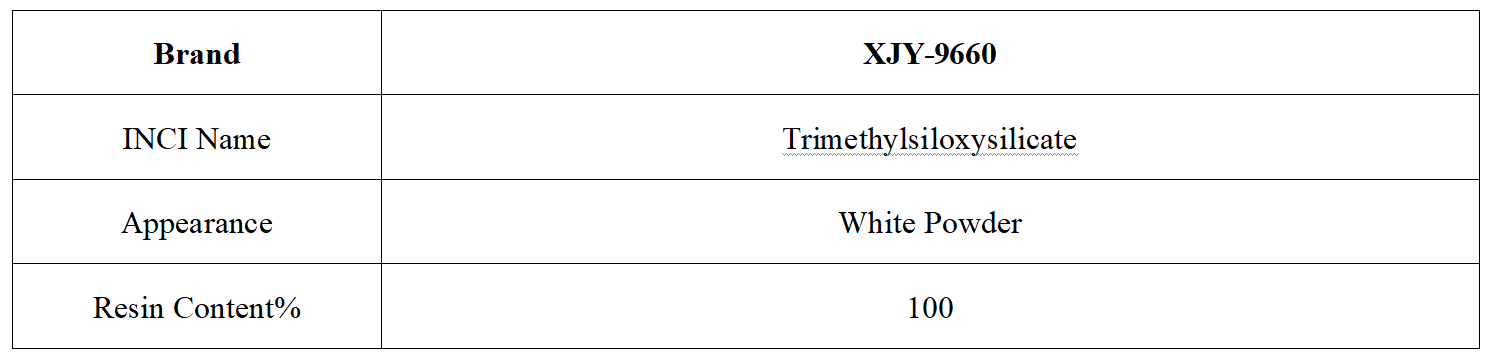

XJY-9660 Trimethylsilanethoxysilicate is a siloxane polymer with a main chain structure consisting of alternating silicon and oxygen atoms. These solid silicones provide film-forming and softening effects, which can provide excellent water resistance and detergent/water wash resistance for many pharmaceutical formulations (such as scar management and so on). It can be added to silicone gel for hypertrophic or keloid scars.

(3) Minimally invasive interventional devices

In vascular embolization therapy, temperature-sensitive silicone gel can be cured in situ after injection through a catheter, and its curing time (20-90 seconds) and swelling rate (150-300%) can be precisely regulated. Animal experiments have shown that 0.5mm diameter gel particles can achieve precise embolization at the capillary level, and the degradation rate is controlled at 85%±5% at 3 months after surgery.

2. Electronics and energy industries

(1) Highly reliable electronic packaging

In IGBT module packaging, the CTE (coefficient of thermal expansion) of silicone gel can be adjusted to 30-50 ppm/°C to achieve mechanical matching with semiconductor chips. Its volume resistivity is>1×10¹⁵ Ω-cm, and its resistance to the electrical tracing index is≥600V, guaranteeing the long-term stability of the device under the working conditions of -55℃ to 200℃. A new energy vehicle electronic control module test shows that the use of silicone gel encapsulation thermal cycle life increased to more than 3,000 times.

(2) Lithium battery safety protection

For thermal runaway protection of power battery, flame retardant silicone gel can form a carbonized layer with an expansion multiplier of 20-50 times and an oxygen index of >32%. Experimental data show that with the battery module coated with a 2mm gel layer in the pinprick test, the highest temperature rise was reduced by 65%, and smoke release was reduced by 80%. At the same time, its thermal conductivity of 1.5W/m-K can improve the temperature uniformity between the cores.

(3) Long-lasting protection of photovoltaic modules

When the two-component additive molding silicone gel is used for potting of the PV junction box, the curing shrinkage rate is <0.1%, and the light transmittance rate is >90% (400-1100nm band). After 3000 hours of double 85 aging test, the yellowing index ΔYI<2, which ensures the requirement of 25 years of service life of the module. Its bonding strength is >2MPa, which can resist the impact of 15mm hail.

3. Industrial manufacturing

(1) Precision mold manufacturing

In the field of microstructure replication, the compounding precision of silica gel can reach a submicron level (Ra<0.1μm). By adjusting the concentration of platinum catalyst, an adjustable curing time window of 10-120 minutes can be realized, which is suitable for batch replication of precision components such as MEMS sensors.

(2) Vibration and noise control

After a high-speed rail bogie adopts a damped silicone gel layer, the vibration transmission loss in the 200-5000Hz frequency band is improved by more than 12 dB. Its dynamic energy storage modulus (G') is maintained in the range of 0.1-1MPa from -40℃ to 150℃, and the loss factor tanδ>0.5, effectively suppressing broadband vibration.

(3) Flexible Sensor Substrates

Stretchable silicone gel (elongation at break>800%) and carbon nanotubes made of composite piezoresistive sensors, sensitivity factor of 5-10, in the 100% strain range of resistance change linearity R²>0.98. Applied to the flexible electronic skin, it can identify the dynamic pressure changes of 0.1-10N.

4. Emerging application areas to expand

(1)Soft robot drive medium

The dielectric elastomer silicone gel in 3kV/mm field strength can realize 80% of the surface strain, a response time <50ms. through the multi-layer stacked design of the bionic gripper can be lifted 200 times the weight of the object, with a cycle life of more than 10⁶ times.

(2)Aerospace Specialty Applications

Atomic oxygen-resistant silica gel is used as an insulating layer for satellite cables with a mass loss rate of <0.1mg/cm²-h in a low Earth orbit environment (atomic oxygen flux of 10¹⁵ atoms/cm²-s). Its vacuum outgassing rate <1×10-⁷ Torr-L/s-cm², which meets ASTM E595 standard.

(3) Cultural heritage protection

For the reinforcement of fragile cultural relics, Young's modulus of nano-SiO₂-reinforced silica gel can be adjusted to 0.5-5MPa, which matches the mechanical properties of ancient paper and textiles. The accelerated aging experiment verified that the material yellowing index ΔE <3 (1000 hours of UV irradiation), and has reversible removal characteristics.

5. How to make the development of silicone better?

In the next five years, with the integration of molecular simulation technology and AI material design, the silicone gel group will make breakthroughs in the direction of programmed response (multi-field coupling such as temperature/light/magnetism) and integration of structure and function, and the application boundary will continue to be extended to cutting-edge fields such as bioelectronics and quantum device packaging, cutaneous and aesthetic surgery. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the silicone gel field and support the provision of diversified customized solutions.