Semiconductor materials are at the heart of modern electronics, and as technology continues to advance, so do the performance requirements for semiconductor materials. Moore's Law is facing the physical limit of the challenge today, the semiconductor industry is experiencing a full range of changes from material innovation to packaging technology. What is the reform of silicone electronics semiconductor industry?

Because of its unique physicochemical properties, silicone materials are gradually showing broad application prospects in the semiconductor field, including its application in packaging materials, photoresist auxiliaries, organic optoelectronic devices, etc., which is reshaping the design and manufacturing paradigm of semiconductor devices. From chip packaging to flexible electronics, from 5G base stations to quantum computers, organosilicon polymer materials are pushing the boundaries of semiconductor technology to expand with a market growth rate of more than 12% per year.

The following five aspects of the application of silicone in the electronic semiconductor industry:

- What are the silicone material properties?

- What are the advantages of silicones?

- What are the applications of silicone in semiconductors?

- What are the challenges of silicone in semiconductor applications?

- How to make silicone perform better?

1. What are the features of silicone materials?

(1) Molecular Structure Advantages

The main chain of silicone (polysiloxane) consists of alternating silicone-oxygen bonds, with a bond energy as high as 452 kJ/mol, which is more thermally stable than traditional carbon chain polymers (C-C bond energy of 348 kJ/mol). The spatial site resistance effect of the side-chain methyl group makes its glass transition temperature (Tg) as low as -120℃, and its elastic modulus is stable within the range of -50℃ to 250℃, which is perfectly suited to the requirements of semiconductor devices working in a wide range of temperatures.

(2) Breakthrough in dielectric properties

Through the introduction of functional groups such as phenyl, the dielectric constant of silicone can be regulated between 2.3-3.2 (1MHz), and the tangent of the loss angle is less than 0.001.

(3) Thermal management innovation

Nanometer boron nitride doping technology makes the thermal conductivity of silicone thermal interface materials (TIM) break through 8 W/mK.

2. What are the advantages of silicone?

Silicone materials have a multifaceted protection of semiconductor devices, mainly in the following areas:

(1) Electrical insulation protection

Silicone materials have excellent electrical insulation properties, and can effectively prevent the semiconductor device in the high voltage and high current conditions of the electrical breakdown phenomenon. Its high dielectric strength and volume resistivity can protect the chip terminal passivation layer and the device's internal electric field concentration location of the insulation.

(2) High and low temperature protection

Silicone materials can maintain stable performance at extreme temperatures, its long-term use of the temperature range is usually between -50 ℃ to 220 ℃. This temperature-resistant characteristic allows semiconductor devices to work properly in high or low-temperature environments while avoiding thermal stress damage caused by temperature changes.

(3) Moisture, dust, and corrosion protection

Silicone materials have good hydrophobicity and waterproof performance, and can effectively prevent moisture and dust from entering the package inside, thus protecting the semiconductor device from environmental influences. In addition, its chemical resistance can resist the erosion of common chemical substances, extending the service life of the device.

(4) Shock absorption and impact protection

Silicone materials are soft and have good impact resistance and shock absorption. Its low-stress characteristics can reduce the pressure on the chip in the encapsulation process, to protect the chip from mechanical damage.

(5) No by-product generation

In the curing process, silicone gel (especially molded silicone gel) does not produce by-products, to avoid the by-products caused by bubbles and shrinkage problems. This gives it a significant advantage in high-precision encapsulation and can improve the reliability of encapsulation.

(6) Strong adhesion

Silicone materials have good adhesion and low viscosity to a variety of materials (such as metals, plastics, ceramics, etc.) to ensure that the encapsulation material and the chip and the substrate between the firm connection, thereby improving the overall stability of the package.

(7) Self-healing

Silicone materials are self-repairing and can be restored to a certain extent due to mechanical stress or thermal stress caused by damage. This characteristic helps to further improve the reliability and service life of semiconductor devices.

(8) Transparency and optical properties

Silicone materials have good transparency and are suitable for applications that require optical properties, such as LED packaging. Their high transmittance and refractive index can effectively improve the performance of optoelectronic devices.

(9) Environmental friendliness

Silicone materials are environmentally friendly during production and use, in line with modern electronics manufacturing requirements for environmental protection.

(10) Customizable

Silicone materials can be adjusted to meet different packaging needs by adjusting the formula and process, such as adjusting its viscosity, curing time, thermal conductivity, and so on. This customizability makes it possible to adapt to a variety of complex semiconductor packaging processes.

3. Silicone in the semiconductor electronic applications?

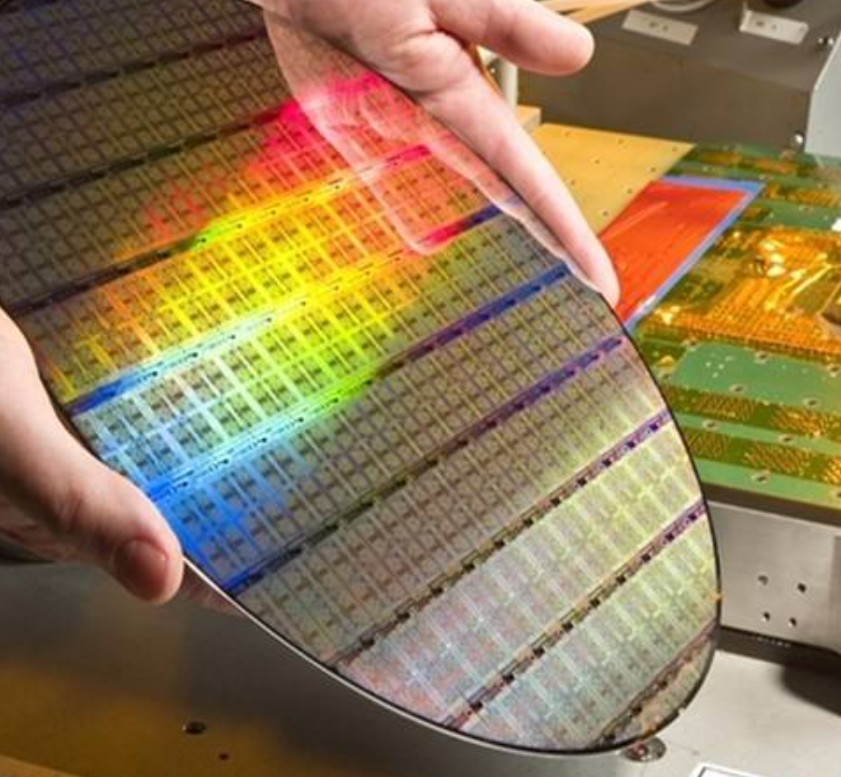

3.1 Silicone in Semiconductor Packaging

(1) Packaging materials: Electronic grade silicone sealant has excellent electrical insulation, heat resistance, and mechanical stability, widely used in semiconductor packaging and other electronic assemblies. For example, in the IGBT (insulated gate bipolar transistor) packaging, silicone sealant adhesive can provide insulation, vibration, fast curing process, and isolation from external corrosive media such as moisture, air, etc., to protect the IGBT chip in electronic systems.

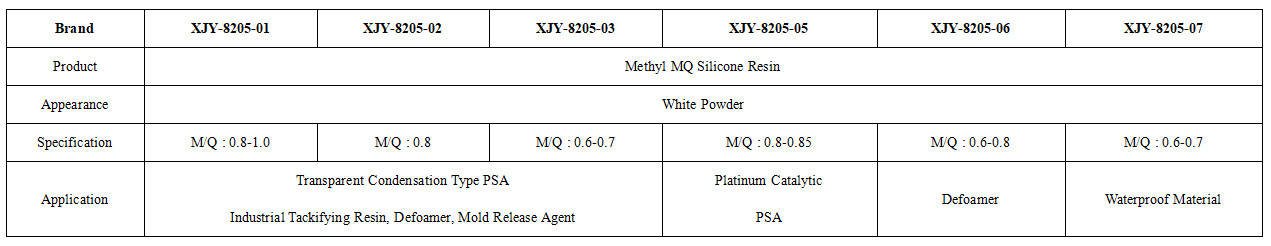

XJY-8205 MQ resin is the product of the co-hydrolysis of tetraalkoxysilane (Q unit) and trimethylalkoxysilane (M unit). It can be used as a reinforcing material in the encapsulation material and has the effect of anti-vibration and insulation.

(2) Photoresist auxiliary materials: in the semiconductor manufacturing lithography process, silicone as Si-BARC (silicon-based anti-reflective coating) materials, conformal coating coated in the Si substrate and photoresist between the surface can reduce the photoresist under the surface of the light reflection, so that most of the energy in the exposure process is absorbed by the photoresist, so as to improve the accuracy of the photolithography process and optical properties.

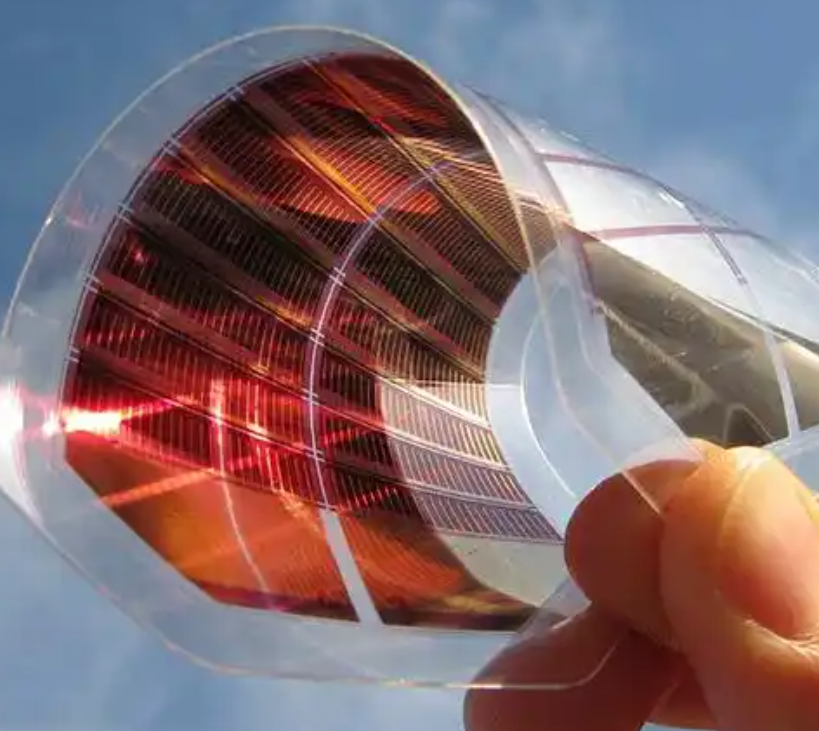

3.2 Silicone in organic photovoltaic devices

(1) Organic solar cells: silicone materials can be made into thin films, and the use of its semiconductor properties, can produce organic solar cells in electronic equipment. This battery has the advantages of low cost, lightweight, flexible, etc., suitable for application in large-area solar power generation systems.

(2) Organic LED: silicone materials also have important applications in organic LED. By optimizing the structure and properties of silicone, the luminous efficiency and stability of organic LED can be improved.

(3) Organic thin-film transistors: organosilicon thin-film transistors can be used to manufacture flexible display screens and transparent electronic devices. Compared with the traditional silicon-based transistors, silicone thin film transistors have better flexibility and transparency, to meet the future demand for thin, light, and bendable electronic products.

3.3 silicone in other semiconductors

(1) Optical sensors: silicone materials are also used in the manufacture of optical sensors. Its good optical properties and stability enable it to be used in the manufacture of high-precision optical sensors.

(2) LCD display backlight unit: in the manufacture of LCD display backlight unit, silicone as a reflective layer and light diffusion layer material, can improve the brightness and uniformity of the display.

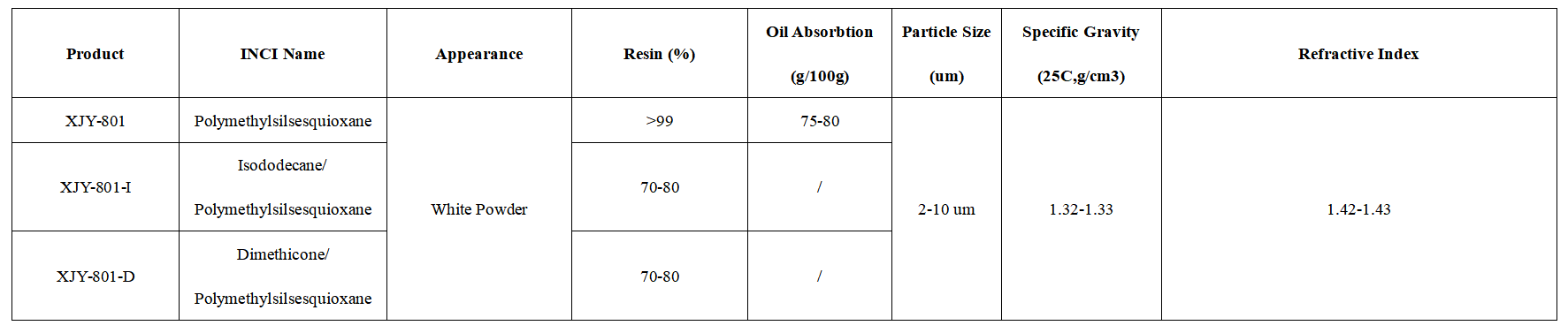

XJY-801 polymethylsilsesquioxane (spherical silicone resin powder) can be widely used in high-grade transparent PC lamps and lanterns, lampshades, light boxes, flat panel LCD light diffusion boards, and so on. It is a kind of ultrafine spherical powder material with both organic and inorganic characteristics, which is in the shape of a three-dimensional network sphere, with good optical properties, dispersion, lubricity, heat resistance, and excellent silky feel.

4. What are the challenges of silicone in semiconductor applications?

(1) Performance stability: Although silicone materials have many advantages, at high temperatures, high humidity, and other extreme environments, performance stability still needs to be further improved.

(2) Material purity: semiconductor applications require a high degree of material purity, silicone materials in the purity control challenges.

5. How to make silicone perform better?

Silicone technology shows broad application prospects in the semiconductor field because of its physical properties. From encapsulation materials to organic optoelectronic devices, the application of silicone for the development of the semiconductor industry and electronic components(mobile phones) provides new ideas and methods. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the electronics silicones field and support the provision of diversified customized solutions.

![]()