In recent years, silicone materials, with their unique physicochemical properties, have gradually become one of the core ingredients in the design of cosmetic formulations. What are the innovations of silicones in cosmetics?

Silicone compounds have been used in more than 65% of skincare, color cosmetics, and hair care products, other silicone emulsifiers and their applications cover key areas such as skin-feel modulation, formulation stability enhancement, and efficacy ingredient delivery. From basic physical improvement to functionalized design, silicone materials continue to drive technological innovation in the cosmetics industry.

The following six aspects introduce the innovative applications of silicone in beauty cosmetics:

- What are the advantages of silicone materials?

- How do silicones work in cosmetics?

- What are the applications for silicone cosmetics?

- How to meet the challenges of silicone color cosmetics?

- What should be the future development of silicone chemicals?

- How to make silicone cosmetics better performance?

1. What are the advantages of silicone materials?

(1) Physical and chemical stability

Silicone compounds (Silicones) with a silicon-oxygen bond (Si-O-Si) as the main chain structure, with excellent thermal stability and chemical inertia. Their decomposition temperature is generally higher than 300°C. They remain stable in the conventional pH range of cosmetics (4.5-8.5) and do not react with the active ingredients in the formulation. This property makes it an ideal carrier for sensitive ingredients such as sunscreen agents and vitamin derivatives.

(2) Surface Activity and Spreadability

The unique molecular structure of silicones gives them an extremely low surface tension (approx. 21 mN/m), which is significantly better than that of conventional oil-based ingredients (approx. 30 mN/m). This characteristic brings two major advantages: in skin care products, it can form a uniform breathable film layer in sensitive skin, and in color cosmetics products, it can realize rapid spreading and reduce the resistance to application by more than 40%.

(3) Sensory modification

By adjusting the chain length and functional group type of silicone, the spreading speed, residual feeling, and gloss of the product can be precisely controlled. For example, cyclopentadimethylsiloxane (D5) evaporation rate of 0.8 mL/h-cm², can realize the “instant absorption” of the skin feel experience.

2. How to use silicones in cosmetics?

2.1 Volatile silicone oils

(1) Cyclic siloxane (D4/D5/D6): molecular weight 300-500 Da, volatilization rate gradient design to meet the needs of different products. Applied sunscreen spray can reduce the sticky feeling, and realize the “no residue” effect in oil control lotion.

(2) Linear silicone oils (such as polydimethylsiloxane): Functional differentiation is achieved by adjusting the viscosity (0.65-100,000 cSt). Low viscosity type (<10 cSt) is used in make-up lotion to smooth skin texture and protect clogged pores, and high viscosity type (>1000 cSt) is used in hair conditioner to form a restorative film layer.

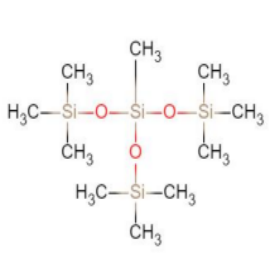

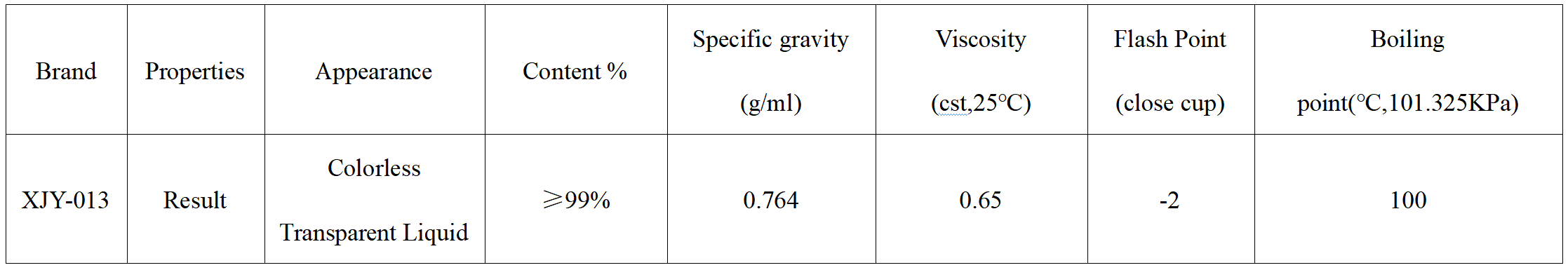

XJY-013 Low viscosity silicone oil

XJY-013 is an organosiloxane that can be used as a structure control agent for various organosiloxane syntheses, a solvent for organosiloxane syntheses, a structure control agent for drug synthesis, and a dispersant for medical products.

2.2 Modified silicone

(1) Amino silicone oil: the introduction of amino functional group (NH2 value of 0.2-1.5 meq/g), and the formation of ionic bonds with hair keratin. Shampoo and conditioning products, can increase the fit of hair scales by 70% and reduce split ends and breakage.

(2) Polyether-modified silicone oil: By grafting EO/PO chain segments (e.g., PEG-12 Dimethicone), the HLB value can be adjusted in the range of 3-18, with both hydrophilic and lipophilic properties. It achieves micron-level emulsification in make-up remover oils and increases cleaning efficiency by 3 times.

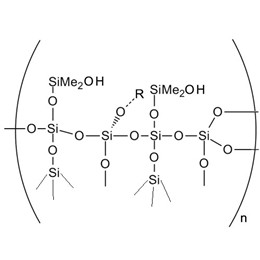

2.3 Cross-linked polymers

(1) Silicone elastomer (e.g. cross-linked polymethylsiloxane): three-dimensional network structure with 0.1-5 μm microporous system, applied to foundation can adsorb sebum up to 80% of its own weight, and extend the holding time of make-up to 8 hours.

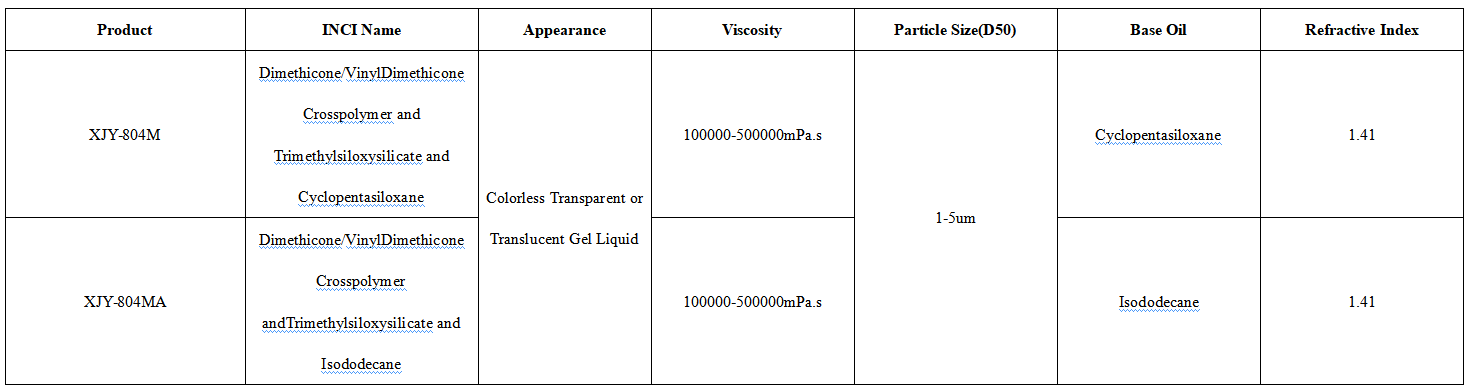

XJY-804M/MA SILICONE RESIN ELASTOMER GEL

XJY-804-M silicone gels is a silicone rubber elastomer gel dispersed in a decamethylcyclopentasiloxane system.

The silicone elastomer is regularly spherical and has excellent slip properties. The special structure of the elastomer gives the product excellent performance in a wide range of formulations and excellent compatibility with other materials used in skin care, color cosmetics, and body care products.

In addition, the product has excellent film-forming properties and has good application prospects in color cosmetics.

(2) Resins (e.g. MQ resin): Rigid backbone structure provides film-forming support, forming an oxygen-permeable film layer in waterproof mascara, with water resistance tested to ISO 16217 standards.

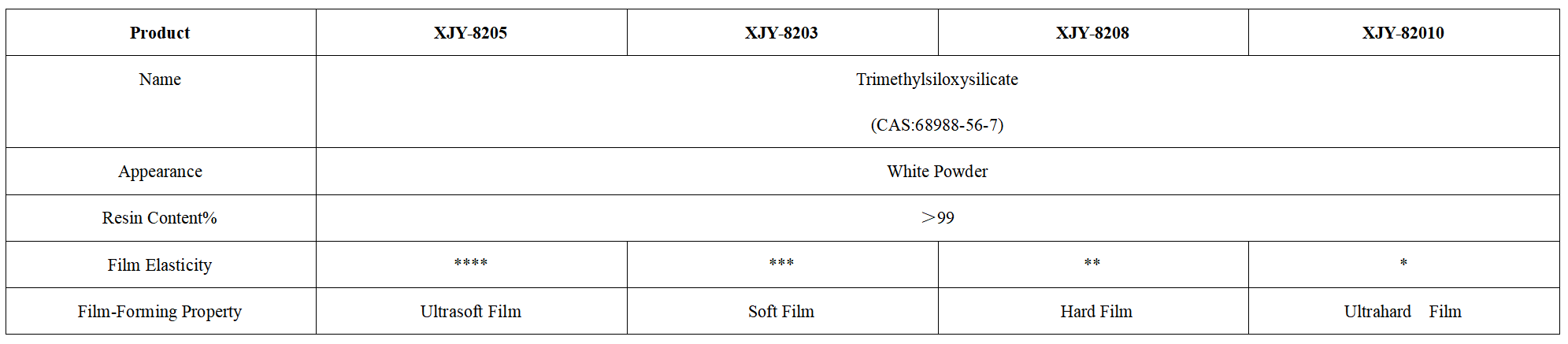

XJY-TMS Trimethylsiloxysilicate

XJY-8203 / 8205 Trimethylsiloxysilicate is a non volatile silicones. A silicone polymer is a polymer whose main chain structure consists of alternating silicon and oxygen atoms. Trimethylsiloxysilicate is a series of solid silicone powders that have been specifically developed to provide film-forming and softening effects. It provides many skin care products with excellent water repellency and detergent/washing resistance, as well as a pliable film with a smooth, pleasant-to-touch surface.

3. What are the applications for silicone cosmetics?

3.1 Skin Care

(1) Barrier repair system: adopting gradient volatile silicone oil system (D5/phenyltrimethylsiloxane oil/polydimethylsiloxanol) to build a bionic sebaceous membrane structure, which can be used for scar reduction and wound healing. Clinical tests showed that transepidermal water loss (TEWL) was reduced by 23% within 28 days.

(2) Activator delivery system: Silicone wax encapsulation technology (e.g., C30-45 Alkyl Methicone) encapsulates retinol in 50 nm microcapsules, increasing the slow-release efficiency by 65% and reducing irritation to 1/3 of traditional formulations.

(3) Sunscreen enhancement program: Phenyltrimethylsiloxane (refractive index 1.56) and titanium dioxide (refractive index 2.7) complex, SPF value synergistic enhancement of up to 1.8 times.

3.2 Color Cosmetics Innovation

(1) Powder surface: using triethoxyoctylsilane to coat titanium dioxide, the oleophilic contact angle of the powder is increased from 45° to 112°, and the uniformity of dispersion in the foundation is increased by 90%.

(2) Long-lasting Makeup Hold: Silicone resin (INCI: Trimethylsiloxysilicate) and acrylate copolymer form an interpenetrating network, which retains 92% of the lipstick color after an 8-hour rubbing test.

(3) Touch regulation: Silicone oil (D5/Polydimethylsiloxysilicate) with different evaporation rates is compounded in the lipstick formula to achieve a balance between initial smoothness (friction coefficient 0.15) and final matte feeling (gloss 45GU).

3.3 Hair Care Technology

(1) Thermal protection system: Amino silicone oil and panthenol are compounded to form a heat transfer barrier at 180°C, reducing hair keratin damage by 58%.

(2) Hair restoration: the use of cationic silicone oil to build a positively charged adsorption layer, the amount of surface deposition per square millimeter of hair up to 0.8 μg, static flyaway reduced by 73%.

(3) Lightweight and smooth: Dimethicone forms a hydrated lubrication layer in the conditioner and hair serums, reducing combing force to 0.6 N and eliminating the accumulation of traditional silicone oils, which can be used for hair masks.

4. How to respond to the challenges of silicone color cosmetics?

4.1 Solutions to Environmental Controversies

In response to the bioaccumulation controversy of cyclic silicone (D4/D5/D6), the industry has introduced multiple solutions to avoid silicones disadvantages:

(1) Developing low cyclic silicone fluids (D4 content <0.1%)

(2) Adoption of linear volatile silicone fluids (e.g. polydimethylsiloxane)

(3) Innovative biodegradable silicone fluids (e.g. polyglycerol-based modified silicone), similar to natural origin.

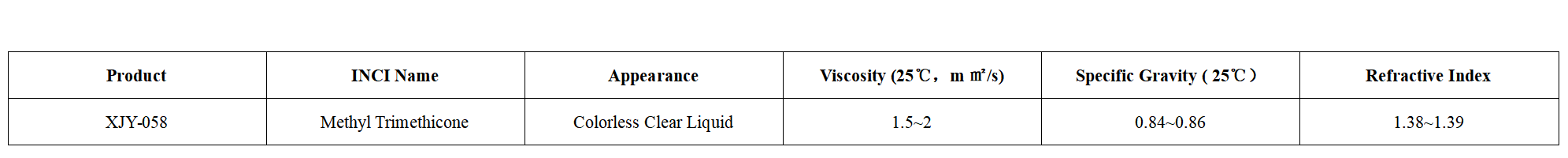

XJY-058 Acyclic silicone oil

XJY-058 is an MT-structured methyltrimethylsiloxane oligomer, acyclic, odorless, colorless, non-irritating liquid with excellent volatility and ductility. Compatible with a wide range of cosmetic products, this silicone derivative leaves the skin surface feeling soft, and its light texture provides a refreshing, non-greasy skin feel. It is mainly used as a conditioning agent for cosmetic chemical formulations as it improves the formulation and texture without leaving any lasting residue.

4.2 Skin Safety Data

The latest EU SCCS assessment report (2022) shows:

Cosmetic-grade silicone oil (purity >99.9%) sensitization rate <0.01

Percutaneous absorption rate <0.05% (OECD 428 standard)

No estrogenic activity (ICCVAM verification)

5. What should be the future development of silicone chemistry?

(1) Intelligent response silicone materials

Develop pH/temperature dual-responsive silicone polymers, such as carboxyl-modified silicone to release active ingredients under sebaceous acid environment (pH5.5) to achieve precise delivery.

(2) Biotechnology integration

Synthesis of siloxanes by enzyme-catalyzed method (e.g. lipase-catalyzed silanol condensation), with product molecular weight distribution (PDI) controlled within 1.05 and purity of 99.99%.

(3) Green preparation process

Supercritical CO2 extraction technology for silicone oil purification, energy consumption reduced by 70%, solvent residue <1 ppm, in line with COSMOS organic certification standards.

6. How to make silicone cosmetics perform better?

With the advancement of precise molecular design technology and green manufacturing process, the new generation of silicone essential elements will open up a new era of cosmetic research and development in the three dimensions of precise efficacy, high-end experience, and sustainable raw materials. In the future, interdisciplinary technology integration will further enhance the depth of silicone ingredients applications in transdermal absorption, microecology regulation,n, and other fields, creating more technological beauty solutions for consumers( such as hair products and so on). How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the beauty field and support the provision of diversified customized solutions.

![]()