Pros & Cons

Advantages

• Wide range of applications

Due to the special chemical structure of silicone oil, it is neither compatible with water or substances containing polar groups, nor is it compatible with hydrocarbons or organic substances containing hydrocarbon groups. Due to the insolubility of silicone oil to various substances, it has a wide range of applications, not only for defoaming in water systems but also in oil systems.

• Low surface tension

The surface capacity of silicone oil is generally 20-21 dynes/cm, which is very low surface tension and smaller than that of water (72 dynes/cm) and general foaming liquids, and improved foam control effect.

• Good thermal stability

Take the commonly used dimethicone as an example, it can withstand 150℃ for a long time and can withstand more than 300℃ for a short time, and its Si-O bond does not decompose. This ensures that the silicone defoamers can be used in a wide temperature range.

• Good chemical stability

Because the Si-O bond is relatively stable, the chemical stability of silicone oil is very high, and it is difficult to chemically react with other substances. Therefore, as long as the preparation is reasonable, the silicone defoamers are allowed to be used in the system containing acid, alkali, and salt.

• Physiological inertness

Silicone oil has been proven to be non-toxic to humans and animals, and its LD50 is greater than 34 g/kg. Therefore, silicone defoamer (with a suitable non-toxic emulsifier, etc.) can be safely used in pulp and paper, food processing, medical, pharmaceutical, and cosmetic industrial applications.

• Strong defoaming power

Silicone defoamer can not only effectively break the unwanted foam that has been existing foam, but also can significantly inhibit the foam and prevent the formation of foam. It is used in a small amount, as long as one-millionth (1ppm) of the weight of the foaming medium is added, it can produce a defoaming effect. Its usual range is 1 to 100 ppm. Not only is the cost low, but also does not contaminate the defoamed material.

Shortcomings

• It is difficult to disperse polysiloxane: polysiloxane is difficult to dissolve in water, which hinders its dispersion in the water system. It is necessary to add dispersant. If too much dispersant is added, the emulsion will be stable and the defoaming effect will be poor. , It is necessary to use a fewer emulsifiers to make the defoaming effect good and the emulsion stable.

• Silicone compound is oil-soluble, reducing its defoaming effect in oil systems.

• Long-term high-temperature resistance, poor alkali resistance.

Classification and performance

Oil (ointment) type defoamer

Oil type defoamer is to use silicone oil directly as a defoamer. It is mainly used in oil-phase foaming systems that do not allow the presence of dispersants and emulsifiers. It is generally believed that silicone oils of different viscosities show different defoaming effects on the same foaming system. The low-viscosity silicone oil-based defoamer has a fast defoaming effect, but has poor sustainability, while the high-viscosity silicone oil-based defoamer has a slow defoaming effect, but good sustainability. Ointment-type defoamer is an ointment-shaped defoamer prepared by adding silicon dioxide, aluminum oxide and other micro-powders to silicone oil. It is mainly used for defoaming non-aqueous systems.

The defoaming effect of dimethyl silicone oil depends on the degree of dispersion of the silicone oil in the foaming system. The higher the degree of dispersion, the better the effect. In order to improve the degree of dispersion, mechanical stirring can be used. Such as high-speed stirring under heating, using a colloid mill to prepare a uniform dispersion of silicone oil and mineral oil, or making silicone oil and white carbon black and other micro powders into an ointment type defoamer in advance, and using it with the help of the dispersion of white carbon black and other micro powders.

Emulsion type defoamer

The silicone oil or silicone paste is made into silicone oil emulsion under the action of strong stirring or emulsifier, which can effectively improve the dispersibility of silicone oil in the water phase. Therefore, it is widely used as a defoamer in water systems. Emulsion-type defoamer is also the most widely used and most widely used defoamer of silicone-based defoamers.

Emulsion-type defoamer is generally prepared from dimethyl silicone oil, emulsifier, emulsion stabilizer and deionized water. The emulsifiers used are mainly non-ionic emulsifiers with low foaming properties, such as Span, Tween and polyethylene glycol, etc. The effect of mixed emulsifiers is better than that of single emulsifiers. The particle size of silicone oil emulsion is the most important control index for emulsion type silicone antifoam and defoamer. In order to obtain a silicone oil emulsion with high defoaming efficiency and good storage stability, the particle size is usually required to be less than 10 μm.

Therefore, in addition to selecting suitable emulsifiers and mixing and grinding process conditions, thickeners processing aids such as polyvinyl alcohol and methylcellulose can also be added to increase the viscosity of the continuous phase.

When using emulsion-type defoamers, you should first understand the temperature, acidity and alkalinity of the foaming system, because they will affect the stability of the emulsion and even lead to demulsification.

Although the emulsion type defoamer has the disadvantages of being difficult to store for a long time, easy to delaminate and easy to deteriorate, it has the characteristics of convenient use, wide application, and obvious defoaming effect and moderate price. With the advancement of technology and chemical processing, emulsion-type silicone defoamer will still have a large space for development.

Defoamer solution

Silicone solution type defoamer can be made by dissolving dimethyl silicone oil into a suitable solvent. Use silicone defoamer prepared from organic solvents such as polychloroethane, toluene and xylene. It can be used for the defoaming operation of the oil-soluble medium, and the organic silicone defoaming agent prepared from water-soluble organic solvents such as hexylene glycol and glycerin is selected. It can be used for aqueous solutions defoaming. The preparation process of the solution-type defoamer is very simple. It is easy to use, and the silicone oil is dispersed in the foaming liquid with the benefit of organic solvent with a defoaming effect. At the same time, some solvents will also play a certain defoaming effect during the diffusion process. However, this method has not been widely used, because a large amount of use will increase the cost of defoaming agents and may cause environmental pollution.

Solid defoamer

Solid defoamer has the characteristics of good storage stability, convenient transportation and convenient use. It can be used not only in the production of nonfoaming and low foaming washing powder, but also on other occasions requiring a defoaming operation.

What is the preparation method for solid silicone defoamers?

There are three preparation methods:

(1) organic silicone oil is directly dispersed on the surface of the solid carrier;

(2) Melt the organic silicone oil with a fatty alcohol, fatty acid, fatty amide, fatty acid ester or paraffin with a low softening point, and then attach the molten body to the surface of the solid carrier;

(3) The organic silicone oil is mixed with the film-forming material so that the film-forming material is encapsulated outside the defoaming component of the organic silicone oil to form dispersed solid particles.

Modified silicone oil type defoamer

Modified silicone oil introduced part of the hydrophilic polyether chain segment of methyl silicone oil, can become a self-emulsifying defoamer, in the foaming system to maintain dispersion for a long time, extending the service life of the defoamer. Currently used as defoamer commonly used modified silicone oil is polyether silicone oil, fluoroalkyl silicone oil, and long-chain alkyl silicone oil, their application and effect are notable.

End-based, side-based and branched polyether silicone oil can be used as a defoamer. They all have a clear cloud point, and only above the cloud point, there is strong defoaming, while below the cloud point there is a role in promoting foaming. In addition, the use of polyether silicone oil with strong emulsification ability, and silicone paste compound, in the water system can be self-emulsified into a stable, efficient defoamer, and has been widely used as polyester fiber high-temperature dyeing, a variety of lubricants, cutting oils, antifreeze and strong acid system of defoaming.

Long-chain alkyl silicone oil defoamer can be used in fermentation, food processing, medical, textile, petroleum, synthetic rubber and resin, coatings and printing ink, and other various industries. Due to its good affinity for organic materials, long-chain alkyl silicone-based defoamers will not affect the post-processing performance of the product. However, its surface tension increases with the increase of carbon chain, and the defoaming performance decreases, so it is important to choose the right length of the carbon chain. Long-chain alkyl silicone oil is used in the defoaming of both non-aqueous systems and aqueous systems.

The surface tension of fluoroalkyl silicone oil is lower than other silicone oils, so the defoamer formulated by it is more effective in reducing the surface tension of various foaming systems, and the effect is better than other silicone oil defoamers. It is mainly used in the foaming medium of non-aqueous systems that are highly soluble in methyl silicone oil or methyl phenyl silicone oil, such as aliphatic hydrocarbons, aromatic hydrocarbons and naphtha.

Epilogue

Silicone defoamer not only has a good effect to control foam, but also has the characteristics of low dosage, good chemical inertia and can play a role under harsh conditions. It has achieved rapid development in recent years. New varieties and new numbers suitable for different use environments are constantly produced, and the application area is also expanding. In the future, new high-efficiency organosilicon defoamers with strong applicability, which can further improve product quality and equipment utilization will be further developed, especially polyether-modified organosilicon defoamers and lotion defoamers with excellent performance will occupy a major position in the market.

XJY Silicones-First choice raw material supplier of silicone defoamers

- XJY-8205 Methyl silicone MQ resin: is blended with linear polysiloxane and other raw materials to form a silicone polymer with a certain degree of cross-linking. It has a good application effect on defoaming and foam control in industries such as printing and dyeing, water treatment, petroleum exploration, and paper-making.

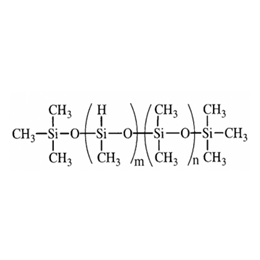

- XJY-701 Polymethylhydrosiloxane/High hydrogen silicone oil: compound to modified silicone oil to produce polyurethane foam stabilizer

- XJY-702 Methylhydrosilxoane, Dimethylsiloxane Copolymer/Low hydrogen silicone oil: as a basic raw material of the foam stabilizers, and defoamers.