Polyether-modified silicone is a polyether-siloxane copolymer (silicon ether copolymer for short) prepared by introducing polyether segments into the siloxane molecule. Polyether-modified silicone defoamer is a new type of high-efficiency silicone defoamer that organically combines the advantages of the two. It is made of polyether with the strong anti-foaming ability and dimethyl silicone oil with strong hydrophobicity and rapid foam breaking as the main components, matching the emulsifier, stabilizer and other components that can organically combine silicone oil with polyether. Silicone defoamer, this silicone defoaming agent has the characteristics of low surface tension, rapid defoaming, long suppression time, low cost, low dosage, and wide application range. The polyether modification of organosilicon makes it have the advantages of the second-class silicone defoamer, and becomes a kind of silicone defoamer with excellent performance and wide application prospects.

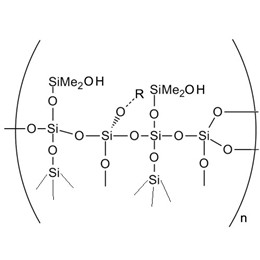

In the silicone ether copolymer molecule, the siloxane segment is a lipophilic group, and the polyether segment is a hydrophilic group. In the polyether segment, the polyethylene oxide chain saves energy to provide hydrophilicity and foaming, and the polyethylene oxide chain saves energy to provide hydrophobicity and permeability, which has a strong effect on reducing surface tension. The groups at the end of the polyether chain also have a great influence on the properties of the siloxane ether copolymer. Common end groups are hydroxyl, alkoxy and so on. Adjusting the relative molecular mass of the siloxane segment in the copolymer can make the copolymer highlight or weaken the characteristics of silicone. Similarly, changing the relative molecular weight of the polyether segment will increase or decrease the proportion of organosilicon in the molecule, affecting the copolymer's performance. Polyether-modified silicone defoamer is easy to emulsify in water and is also called "self-emulsifying defoamer". Above its cloud point temperature, it loses water solubility and mechanical stability, and is resistant to acids, alkalis and inorganic salts, and can be used for defoaming under severe conditions.

In order to improve the lipophilicity of water-based inks, coatings, cutting fluids, etc., part of the methyl groups in the copolymer molecules of the polyether-modified silicone defoamer are replaced with long-chain alkyl groups, which can more effectively exert the defoaming effect. In order to have better defoaming performance below the cloud point temperature, commercial self-emulsifying defoamers are usually equipped with dimethyl silicone oil --- white carbon black paste, at this time under the cloud point temperature Polyether modified silicone surfactants can also be used as emulsifiers for dimethyl silicone oil to play a role in dispersing and emulsifying.

![]()

![]()

XJY Silicones

XJY Silicones can provide XJY-8205D MQ resin that can be applied in the silicone defoamer.

| Item | XJY-8205D |

| Appearance | White Powder |

| Solid content% | >98.5 |

| Molecular weight(g/mol) | 4000-7000 |

| M/Q ration | 0.6-0.8 |

| Bulk density(g/cm3) | 0.25-0.4 |

XJY Silicones as one of the leading silicone manufacturers is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry. Our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.