Wide range of applications:

| Due to the special chemical structure of silicone oil, it is neither compatible with water or substances containing polar groups, nor with hydrocarbons or organic substances containing hydrocarbon groups. Due to the insolubility of silicone oil to various substances, it has a wide range of applications. It can not only use the water system to defoam but also in the oil system. |

Low surface tension:

The surface capacity of silicone oil is generally 20-21 dyne/cm, which is smaller than that of water (72 dynes/cm) and general foaming liquids, and has good defoaming performance.

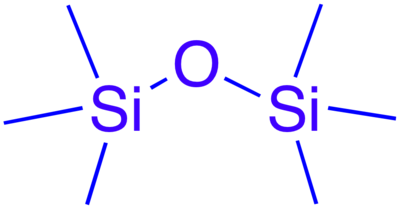

Good thermal stability:

Taking the commonly used dimethyl silicone oil as an example, it can withstand 150°C for a long time and 300°C for a short time, and its Si-O bond will not decompose. This ensures that the silicone defoamer can be used in a wide temperature range.

![]()

Good chemical stability:

| Because the Si-O bond is relatively stable, the chemical stability of silicone oil is very high, and it is difficult to chemically react with other substances. Therefore, as long as the formulation is reasonable, the silicone defoamer is allowed to be used in systems containing acids, alkalis, and salts. |

Physiological inertia:

Silicone oil has been proven to be non-toxic to humans and animals, and its LD50 is greater than 34 g/kg. Therefore, silicone defoamer (with suitable non-toxic emulsifiers, etc.) can be safely used in the food, medical, pharmaceutical and cosmetic industries.

![]()

![]()

![]()

Strong defoaming power:

Silicone defoamer agent can not only effectively break the foam that has been generated, but also significantly inhibits the foam and prevent the formation of foam. It is used in a small amount, as long as it is added to one millionth (1ppm) of the weight of the foaming medium, it can produce a defoaming effect. The commonly used range is 1 to 100 ppm. Not only is the cost low, but also does not pollute the defoamed substance.

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

We are manufacturing and customizing XJY-8205D Methyl MQ resin for silicone defoamer.

| Item | XJY-8205D |

| Appearance | White Powder |

| Solid content% | >98.5 |

| Molecular weight(g/mol) | 4000-7000 |

| M/Q ration | 0.6-0.8 |

| Bulk density(g/cm3) | 0.25-0.4 |

Our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.

![]()