Whenever we agitate the liquid or be introduced into the gas, many bubbles will be generated inside the surface of the liquid, and some bubbles generated by the liquid will quickly break and disappear. Some liquids not only do not disappear, but also gather more and form bubbles. Foam is a dispersion system formed by a large number of bubbles dispersed in a liquid. The dispersed phase is gas and the continuous phase is liquid. Among them, the volume fraction of the foaming liquid is very small, and the foam occupies a large volume. The gas is separated by a continuous liquid film, forming bubbles of varying sizes, which accumulate into foam.

The foaming medium is like a surfactant. A layer of surfactant molecules arranged in an oriented arrangement is adsorbed on the surface of the bubble. When it reaches a certain concentration, the bubble wall forms a solid film. The surfactant is adsorbed on the gas-liquid interface, causing the surface tension of the liquid surface to decrease, thereby increasing the gas-liquid contact surface, so that the bubbles are not easy to merge. The relative density of the bubbles is much smaller than that of the liquid itself. When the rising bubbles penetrate the liquid surface, they adsorb a layer of surfactant molecules on the liquid surface. Therefore, the bubble film with surfactant adsorbed in the air is different from the bubble film in the solution. It contains two layers of surfactant molecules to form a bimolecular film. The adsorbed surfactant protects the liquid film. effect. The organosilicon defoamer is to destroy and inhibit the formation of this film. The organosilicon defoamer enters the bimolecular-oriented film of the foam, destroys the mechanical balance of the oriented film, and achieves the foam breaking effect.

Silicone defoamer is a substance that is insoluble in the foaming medium. It can be dispersed into the foaming medium in the form of liquid droplets, or liquid droplets enclosing solid particles, or solid particles. Moreover, the silicone defoamer has a lower surface tension than the foaming medium, and can spontaneously enter the liquid film to burst the bubbles.

The silicone defoamer is easy to spread on the surface of the solution and automatically spreads out on the surface of the foam. It will take away a layer of solution adjacent to the surface and make the liquid film thin locally to reach a critical thickness. The liquid film ruptures and the foam is destroyed. The faster the silicone defoamer spreads on the surface of the solution, the thinner the liquid film becomes, the faster the foam destruction speed, and the stronger the defoaming effect. Therefore, the reason for the defoaming of the silicone defoamer is that it is easy to spread. The molecules of the silicone defoamer replace the molecules of the foaming agent, forming a film with poor strength. At the same time, part of the solution adjacent to the surface layer is taken away during the spreading process of the organosilicon defoamer, so that the foam liquid film becomes thinner, which reduces the stability of the foam and makes it easy to destroy.

An excellent silicone defoamer must take into account the effects of eliminating and suppressing foam at the same time, that is, it should not only destroy the foam quickly, but also prevent the formation of foam for a long time.

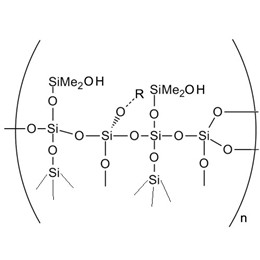

The silicone defoamer added with XJY-8205 Methyl MQ resin can increase the duration of the defoamer. It can make the silicone defoamer system prevent foaming for a long time. The system of MQ resin and silicone defoamer forms a three-dimensional. The three-dimensional structure improves the temperature and corrosion resistance of the system, and increases the defoaming and overflowing capabilities.

XJY Silicones

XJY Silicones as one of the leading silicone manufacturers is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry. Our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.