The photovoltaic (PV) market is an important part of the renewable energy sector and has grown rapidly in recent years. With the global emphasis on climate change and energy transition, the PV market continues to grow, and technological innovation continues to drive industry progress. The cost of photovoltaic power generation continues to decline towards grid parity, and the market space is huge. What about silicone resin in the photovoltaic industry?

Silicone resin in the photovoltaic industry, such as surface glass using glass fibers as well as silicone resin coating to replace the flexible materials in the photovoltaic industry's rapid development of the wave, the application of silicone resin is far from replacing the traditional surface glass in a single role. With the progress of science and technology and in-depth exploration of materials science, this high-performance material is gradually penetrating into more core aspects of the photovoltaic module, leading the industry to a more efficient, more durable, and more environmentally friendly direction.

There are three applications of silicone resin in PV modules:

- Why choose silicone resin?

- What are the applications of silicone in PV?

- How to make better performance of photovoltaic modules?

1. Why choose silicone resin?

Silicone resin(also optical liquid silicone rubber) is widely used as an encapsulation material for PV modules to protect PV cells and improve their stability and service life due to its excellent properties such as weather resistance and electrical insulation.

Silicone resin can not only effectively isolate water vapor and oxygen to protect PV cells from environmental erosion and prolong their service life, but also adjust its molecular structure to enhance the transmittance of light, thereby enhancing the photoelectric conversion efficiency of the cells. In addition, its good flexibility and adhesion ensure that the encapsulation layer and the battery substrate are in close combination for the long-term stable operation of solar cells and provide a reliable guarantee.

Moldable optical silicone elastomers have become the ideal choice for PV back sheet materials due to their excellent weather resistance, UV aging resistance, and good electrical insulation properties. Backsheets modified with silicone resins can effectively withstand extreme climatic conditions, extend the overall service life of the PV system, reduce maintenance costs, and improve overall economic efficiency.

One-component room-temperature vulcanized silicone rubber is used as solar cell frame sealant, junction box sealant, busbar sealant, and thin film module bracket adhesive. This silicone rubber is neutral and protects the battery chips from contamination and corrosion, while the vulcanized silicone rubber is flame retardant. Through the application of silicone sol or silane treatment, a reflection-reducing film is generated on the surface of the battery chip to improve the efficiency of solar cells in absorbing light.

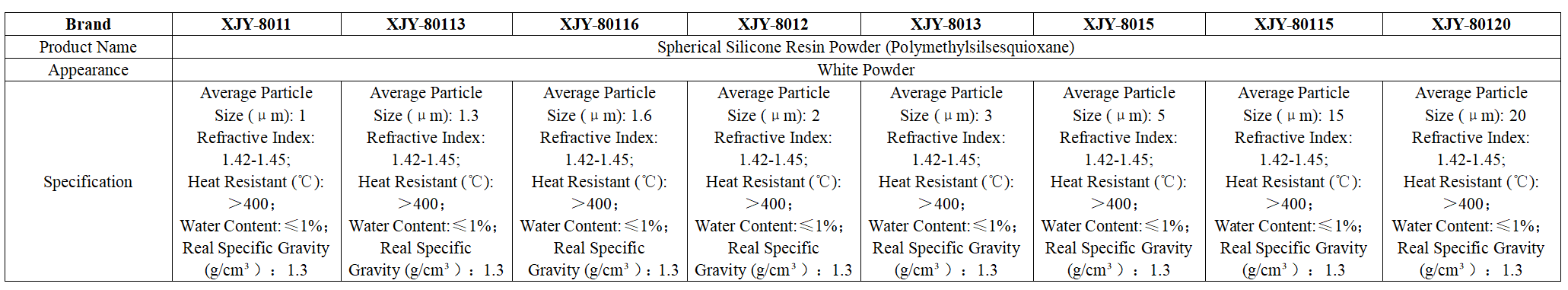

XJY-801 Polymethylsilsesquioxane (spherical silicone resin powder)

It is used as raw material, and acid is used as the catalyst to carry out the hydrolysis reaction first, and then condense under alkaline conditions, and then condense and crystallize into a spherical shape.

Its particle size distribution can be customized. After high-temperature maturation and other processes, the solid product is finally obtained. It can provide a good balance of optical properties in terms of transmittance both its physical integrity, haze, and diffusion effect, and is widely used in high-end transparent PC lamps, lampshades, light boxes, flat panel LCD light diffusion panels, and so on.

2. What are the applications of silicone in photovoltaics?

(1) Photovoltaic encapsulation adhesive

Encapsulation of the photovoltaic module is the key link to protect the photovoltaic cell from the external environment. As an encapsulation material, silicone has excellent weather resistance, UV resistance, and waterproof performance, which can effectively extend the service life of PV modules. At the same time, silicone encapsulation material also has good flexibility and adhesive force, which can ensure the sealing and stability of PV modules.

Silicone resin in the field of photovoltaic encapsulation adhesive application also shows great potential. Encapsulation adhesive is a key barrier to protect PV cells from water vapor and oxygen erosion, its performance is directly related to the power generation efficiency and long-term stability of PV modules.

Silicone resin, due to its low-stress shrinkage, high light transmittance, and excellent chemical corrosion resistance, has become the preferred component in the encapsulant formula, which helps to improve the sealing and durability of the encapsulant layer, and at the same time reduces the light loss and maximizes the photoelectric conversion efficiency.

(2) On the solar cell module

Coat the light-transmitting surface of the solar cell module with a special coating based on silicone resin, which requires fast curing at room temperature, and the cured film layer has an appropriately high refractive index and adheres firmly to the substrate.

In solar cell modules, the chip is surrounded by a transparent material for bonding and fixing.

Compared with the traditional EVA material, the use of liquid silicone rubber filling bonding can extend the working life of photovoltaic cells and improve the efficiency of power generation, especially the application of injection molding liquid silicone rubber filling potting solar cell modules, which can achieve the best results.

(3) Silicone in the application of conductive adhesive

In the photovoltaic module, the conductive adhesive is the key material to realize the electrode connection. Silicone conductive adhesive has excellent electrical conductivity and stability, to ensure the efficiency of photovoltaic components of electrical energy transmission.

In addition, silicone conductive adhesive also has good heat resistance and chemical resistance, can adapt to the photovoltaic module in a variety of harsh environments.

(4) Silicone in the application of photovoltaic coatings

Coating technology is widely used in the photovoltaic industry to improve the power generation efficiency and anti-pollution performance of photovoltaic modules.

Silicone coating has excellent self-cleaning ability and anti-pollution performance, which can effectively reduce the dust and pollutants on the surface of PV modules and improve the power generation efficiency of PV modules, and indoor light fixtures. At the same time, silicone coatings also have good weathering and wear resistance and can protect PV modules from external environmental erosion.

Using methyl phenyl silicone resin as the substrate of the organosilicon coating, this coating has excellent heat resistance and weather resistance and is suitable for the protective coating of photovoltaic power generation structures.

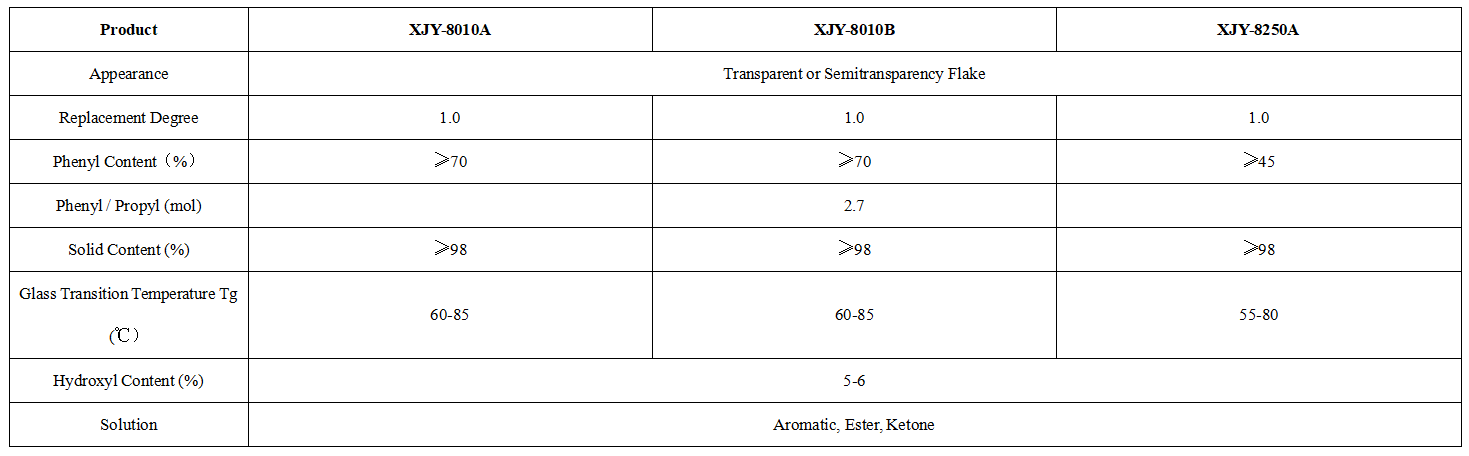

XJY-8010A/B/XJY-83350 Flake Silicone Resin

It can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200°C or a wide operating temperature range, and can be used to prepare various heat-resistant coatings, with heat-resistant insulation grades as high as class H. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200°C or even higher temperatures. High-phenyl silicone resins have excellent radiation and radiation resistance and can also be used in the production of liquid coatings.

Silicone resins have excellent UV resistance and good adhesion with high hardness, and dimensional stability. Silicone resins also have excellent weathering both their physical integrity, low-temperature flexibility, ozone resistance, arc resistance, hydrophobicity, salt spray resistance, and mold resistance. It can be used for existing roofs, kitchen appliances, and more, optical surface geometry.

3. How to make PV module performance better?

Silicone plays an important role in the photovoltaic industry and is a key material for improving the performance and stability of PV modules, LED lighting, and light transmission. With the continuous development of the PV industry, the application areas of optically clear silicone will be further expanded to provide more high-quality material options for the PV industry. Therefore, key bulk materials characteristics can be said that silicone and the photovoltaic industry are closely linked, are an indispensable part of the new energy field. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the photovoltaic field and support the provision of diversified customized solutions.