The medical market will continue to grow as the population ages, health awareness rises, and technology advances. In the future, the medical market will focus more on innovation and quality, and medical devices, biotechnology, telemedicine, and other fields will see rapid development. What are the applications of silicone in healthcare?

Medical grade silicone can be used in medical applications and medical device manufacturing, mainly attributed to their excellent properties. Silicones are biocompatible, chemically stable, breathable, and moisture resistant, which make them ideal for the manufacture of medical devices, coatings, dressings, and artificial organs. In addition, silicones can be formulated to achieve specific properties to meet diverse needs in medical applications. Therefore, silicones have a wide range of applications in the medical field.

There are four aspects to introducing medical silicone

- Wound care

- Silicone skin adhesives

- Dental impression materials

- How can medical silicone performance be improved?

1. Wound care

Wound care is often referred to as silicone dressings. Silicone dressings are suitable for a variety of medical scenarios, including new and old hyperplastic scars or tumor scars on intact skin, and scar care on newly healed wound surfaces. It is suitable for all types of traumatic and post-surgical wounds and is used under medical supervision to enhance pain relief. Further examples are for applying and immobilizing complex wounds such as pressure sores, leg and foot ulcers, and traumatic wounds. Or to treat moderately to highly exuding wounds, including cavities.

Silicone dressings serve a variety of purposes, notably anti-adhesion, wound protection, promotion of healing, reduction of scarring, and pain relief. Silicone dressings are effective in preventing adhesion between tissues by forming a film on the skin surface through its unique surface properties. Secondly, it is biocompatible and breathable, providing a sterile, moist environment conducive to cell growth and repair, thus isolating and moisturizing wounds from external contaminants. In addition, specific components in silicone dressings stimulate fibroblast proliferation, accelerating the wound-healing process and reducing the risk of infection. The silicone material affects the expression level of matrix metalloproteinase-9 (MMP-9), which regulates extracellular matrix remodeling, inhibits excessive collagen deposition, and reduces the probability of scar formation. Finally, the silicone dressing covers and protects the wound and reduces external irritation, thereby reducing patient discomfort.

The silicone foam dressing is able to increase the amount of exudate absorption through the absorbent layer while immobilizing the absorbed exudate in its own molecular structure, preventing the exudate from leaking out. This prevents the internal fluid from oozing out when the dressing is under pressure, causing the wound and surrounding skin to become impregnated, affecting wound healing, and causing rashes or even ulcers on the surrounding skin, leading to lesions or necrosis of the wound.

In addition, some of the dressings that require a certain degree of viscosity, it can be understood as a dressing adhesive, which can be used at the wound with very low viscosity to reduce the pain of the affected area when peeling off the dressing and changing the dressing.

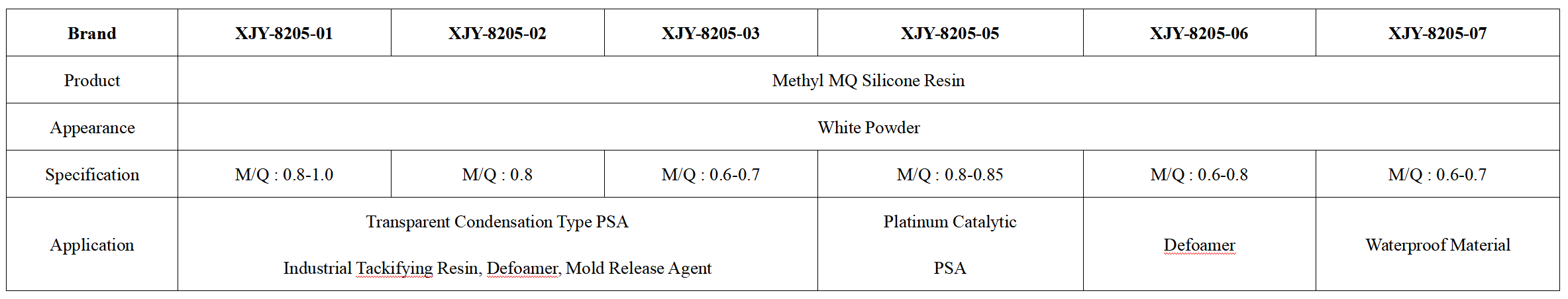

XJY-8205 Methyl MQ silicone resin (medical grade)

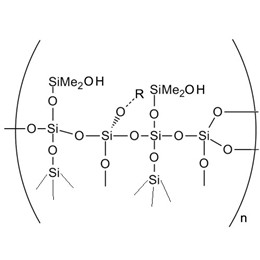

XJY-8205 MQ resin (silicic acid, sodium salt, reaction product with chlorotrimethylsilane and isopropyl aldehyde) is a co-hydrolyzed product of tetraalkoxysilane (Q-unit) and trimethylalkoxysilane (M-unit).

This rubber-like material is widely used in personal care, adhesives, defoamers, and water repellents, and has good, high-release ability in mold release agents for polyurethane processing.

2. Silicone skin adhesives

Silicone skin adhesives are adhesive solutions for a wide range of medical applications where the chemical benefits of silicone (e.g., biocompatibility, skin gentleness, breathability, and abrasion resistance) are important. The main categories are as follows

(1) Advanced wound care, wearable devices similar to silicone with certain adhesive silicone dressings; characterized by high adhesion, long wear time, and gentle removal. Solvent-free, two-component system curing; low viscosity; non-allergenic and irritating; no cytotoxicity; low peeling force, gentle adhesion to the skin and other characteristics.

(2) Silicone Medical Pressure Sensitive Adhesives (PSA): Silicone medical PSA is suitable for a variety of applications, including wearable devices, and prosthetics fixed to the body and skin. Low viscosity material, can be coated using traditional tape coating equipment; high adhesion and fit to the skin; non-allergenic; non-irritating; waterproof and sweatproof; long-lasting, non-adhesive, non-flaking properties.

(3) Silicone adhesive for transdermal drug delivery: Silicone adhesive for controlled drug delivery

XJY-301 Silicone pressure-sensitive adhesive (condensation type)

Silicone pressure-sensitive adhesive is a pressure-sensitive adhesive product that uses organosiloxane as the main solid component and toluene, the main component is mainly made of the condensation of raw silicone rubber and (XJY-8205) series MQ resin.

3. Dental impression materials

3.1 What properties are needed for silicone gel dental impressions?

(1) Excellent dimensional stability

(2) Resilience

(3) Thixotropic properties

(4) High tear strength

(5) Reasonable curing time (not too long)

(6) Non-stick, with a certain consistency

(7) Waterproof

3.2 Dental impression materials on the market What are the types of impression materials?

(1) Alginate-based impression materials

It is a powdered material that is mixed and then solidified. The advantages are that it is cheap and easy to handle. The disadvantage is also obvious, the shrinkage is relatively large and cannot reflect the state of the teeth more accurately. For the production of fixed dentures, such as inlays, porcelain crowns, cast porcelain crowns, precision attachments, and other techniques, it cannot be used to take partial impressions of dentures.

(2) Agar-based impression materials

Used more commercial name is also called “cold days material”, cheaper, and can be used for fixed repair, the disadvantage is is easy to break and brittle.

(3) Silicone silicone dental impression materials

Higher precision can be used for the production of various restorations. It has become more and more popular in China only in recent years, but there are still not many hospitals and clinics that use it. Also divided into three categories:

a: polycondensation silicone rubber: the lowest precision in the silicone rubber impression material;

b: polymerization class silicone rubber: one of the highest precision materials. Very stable, is one of the preferred impression materials, the price is higher;

c: Polyether rubber: one of the highest precision materials, has good fluidity, and has higher prices.

3.3 What are the advantages of silicone rubber systems for dental impression rubber?

Plus molding silicone rubber containing vinyl polysiloxane as the base polymer, with silicone hydrogen bonded polysiloxane as a crosslinking agent, under the action of platinum catalysts, hydrogen silicification addition reaction occurs, crosslinking into elastomers. Silicone rubber has good biosafety, good fluidity and plasticity, broadly adjustable curing time, its crosslinked elastomers have good compatibility with gypsum materials and elasticity, mechanical strength, and dimensional stability, and can be sterilized without reducing the quality of the impression in order to control cross-infection. It solves some defects of traditional impression materials, such as large shrinkage of alginate agar impression material, easy fracture after making the model of agar impression material, and poor tear strength. Room temperature two-component molding silicone rubber impression material curing time is short, fast solidification in the oral cavity, good dimensional stability, fine replication is good, good elasticity and elastic recovery, as well as good operating properties. Therefore, it is recognized as a promising oral impression material at home and abroad.

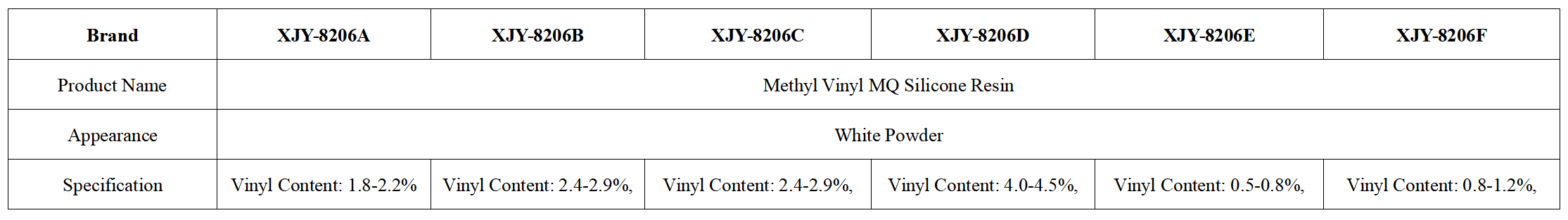

XJY-8206 Methyl Vinyl MQ Silicone Resin

It is a solid powder resin used as a reinforcing filler for additive molded silicone rubber (high-concentration rubber) with high transparency and hardness.

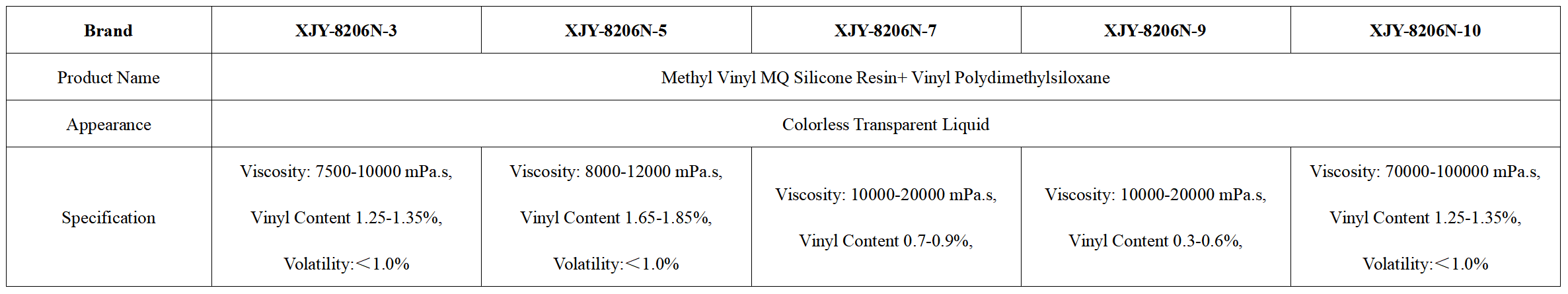

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Dimethicone

It is a colorless and transparent liquid silicone rubber LSR composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used with other additives for liquid silicone rubber (high-consistency rubber) has good reinforcing and hardening properties and is widely used in the medical field and electronics.

4. How can medical silicone performance be improved?

Different from versatile material, silicones are a class of polymers that contain the elements silicon and oxygen in their molecular chain, the advantages of medical silicone are mainly reflected in its biocompatibility, heat resistance, chemical stability, physical strength in the chemical process, and formability in injection molding and compression molding. It is safe and reliable, harmless to the human body; has good resistance to temperature and compression; and can be formulated to achieve specific properties to meet a variety of medical needs. In addition, medical silicone is easy to process and mold and is suitable for the manufacture of a broad range of medical devices (Such as baby bottle nipples). How can we improve the competitiveness of our products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.