The paint market is developing steadily and its market size continues to expand. In recent years, with the acceleration of urbanization and the enhancement of environmental awareness, the coating industry has gradually developed in the direction of green, environmental protection, and high performance. Technological innovation and market demand promote product diversification, architectural coatings(silicone roof coating), industrial coating, and other areas to maintain steady growth. Meanwhile, the export volume of coatings is also climbing year by year, showing strong international competitiveness. What about silicone coatings?

Silicone coatings have a variety of advantages, mainly including strong weather resistance, ozone, ultraviolet, and atmospheric with excellent stability, suitable for outdoor use; able to withstand high temperatures of 200-250 ° C, some special varieties are even able to withstand temperatures as high as 300-500 ° C; corrosive substances such as acids, alkalis, salts and other corrosive substances have a better ability to resist, able to protect the substrate from corrosion; low VOC emissions, less harmful to the environment and human body, environment and the human body less harm.

The following seven aspects of the application of silicone coatings:

- What is silicone coating?

- What are the properties of silicone coatings?

- Why choose silicone coatings?

- Is silicone coating safe?

- What are the precautions for silicone coatings?

- How to use silicone coatings?

- How to make the performance of silicone coatings better?

1. What is silicone coating?

Silicone coatings, known as the coatings “noble”, are a silicone polymer or silicone-modified polymer as the main component of high-tech coatings. Silicone coatings are unique in many coating fields because of their excellent weather resistance, corrosion resistance, and excellent adhesion. It not only has the protection and decorative functions of many other coatings but also shows extraordinary stability and durability in extreme environments(ponding water) as if the coated objects (asbestos cement, wood, industry, metal roofs, polyurethane foam) are covered with a layer of tough and indestructible protective armor.

2. What are the properties of silicone coatings?

Heat resistance: in the temperature range of -40 degrees to 180 degrees, it can maintain excellent performance, the color does not fade, and the paint film does not come off, as if it is a resolute warrior.

Weather resistance: Whether it is windy, rainy, or sunny, it can provide rock-solid protection for the coated objects.

Corrosion resistance: in the face of acid, alkali, salt, and other chemical attacks, it can easily cope with, it to protect the safety of the coated object.

Environmental protection: the iteration of new technology makes the product zero formaldehyde, zero benzene, and environmental protection to the extreme.

Touch: skin-friendly material, touch as if the touch of the skin.

Softness: with a certain degree of pressing softness, suitable for the elderly room, or young children's room.

Easy to scrub: can be scrubbed many times.

Lotus leaf effect: non-absorbent, can effectively stop moisture mold and shedding.

Elasticity: elasticity, even if living for a long time will not easily cause wall cracks.

3. Why choose silicone coating?

(1) The molecular structure of silicone coatings contains a unique silicone-oxygen bond, which gives it extraordinary heat and cold resistance, whether in the scorching heat of summer or in the bitter winter cold attack, can maintain the integrity of the coating and the stability of the performance, as the natural evergreen tree, everlasting and new.

(2) Silicone coatings, its excellent chemical resistance, making silicone coatings in the face of acid, alkali, salt, and other corrosive substances, such as erosion, still be able to calmly, as if a battle-hardened warrior, fearless.

At the same time, good electrical insulation properties and low surface energy characteristics, let it in the electrical, marine, aviation, and other high-end fields, become an indispensable protection messenger.

(3) In the coating process, silicone coatings show excellent construction performance, whether brushing, rolling, or spraying, can be easily managed, and rapid drying, and film uniformity, for the coating engineers to provide a great deal of convenience and creative space. With its unique luster and color, it not only enhances the aesthetics of the coated objects, but also invisibly adds value to the product, making it stand out in the fierce market competition, and become the focus of the eyes of consumers and favorites.

4. Is silicone coating safe?

(1) Impact on human health:

When silicone coatings are used and handled in a proper environment, their effects on the human body are minimal.

People should avoid prolonged exposure to paint sprays, odors, etc., and direct skin contact with silicone coatings to reduce potential health risks.

(2) Impact on the environment:

Silicone coatings do not discharge wastewater and highly toxic waste containing pollutants during manufacture and use, and the impact on the environment is relatively small.

However, if silicone coatings are used in large quantities or handled improperly, they may still cause some pollution to the environment. Therefore, residues and wastes should be handled carefully after use to avoid polluting the environment.

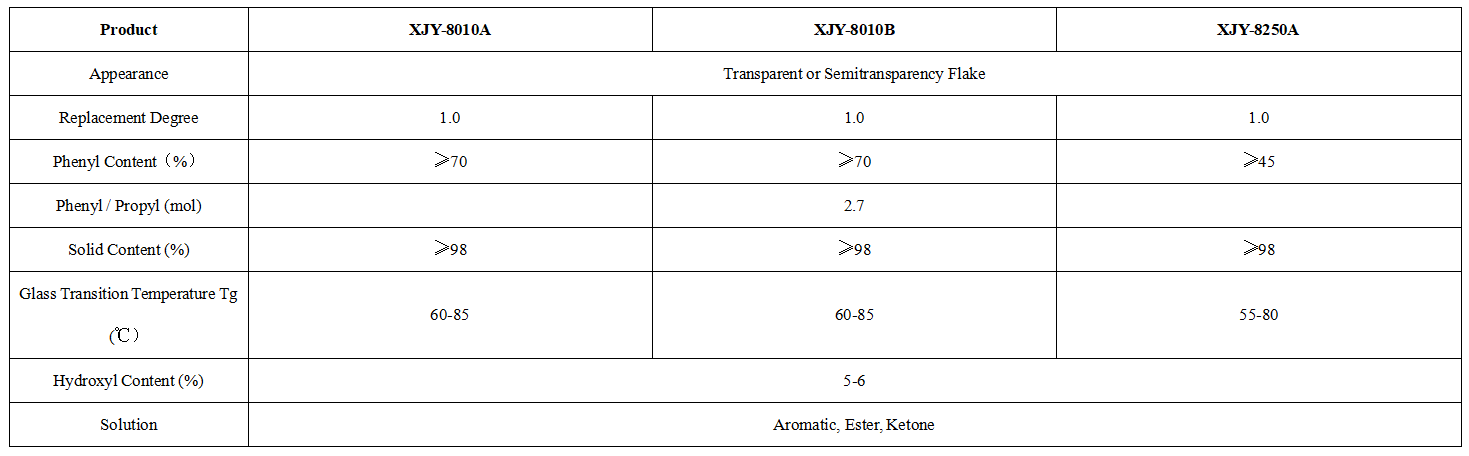

XJY-8010A/B/XJY-83350 Flake Silicone Resin

It can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of silicone resin is its excellent heat-resistant property, which hardly decomposes at 200°C or even higher temperatures, and can be used to prepare various heat-resistant coatings with highly reflective, heat-resistant insulating grades up to class H. Silicone high solids resin has excellent radiation and radiation-resistant properties and can be used to make high-temperature resistant powder and liquid coatings. Silicone resins have excellent resistance to radiation and proton oxygen attack. Silicone resins have excellent UV resistance and good adhesion. Silicone resins also have excellent resistance to weathering, ozone, arcing, hydrophobic moisture, salt spray, and mold. It can be used on existing roofs, kitchenware, etc.

5. What are the precautions for silicone coatings?

(1) Selection of products:

You should select products that meet national and industry standards to ensure the quality and safety of the coating.

(2) Personal protection:

In the process of using silicone coatings, personal protective equipment such as respirators, gloves,s and protective glasses should be worn to minimize the harm to the body.

(3) Use environment:

It should be used in a well-ventilated environment, and try to avoid prolonged contact with silicone coating spray and odor.

(4) Storage and transportation:

It should be kept dry and cool during storage, avoiding direct sunlight and a high-temperature environment. Care should be taken to prevent leakage and damage during transportation.

6. How to use the silicone coating?

(1) Before painting, the surface of the object must be cleaned of dust, oil, welding slag, rust, old paint film, etc. The steel surface should be sandblasted and shotblasted to Sa2.5 level, and the surface of local repair should be polished to St3 level. It is strictly prohibited to bring in water during construction.

(2) This material can be constructed by single-component mixing. The ratio of two-component coating is: component A: component B = 14.2kg (big bucket): 4.3kg (small bucket). Two-component construction proportioning method is as follows: open the large mouth of component A completely, add component B into component A, and mix well. It can be painted.

(3) The paint is too thick and can be diluted with a special thinner. Unmatched materials should be sealed and stored.

(4) rainy days or relative humidity greater than 75%, should stop construction.

(5) The product should be stored in a cool, dry place, prevent direct sunlight, isolated from fire, and away from heat sources.

(6) The storage period of twelve months, after the expiration of the period should be tested for various technical indicators, such as indicators to meet the requirements, can continue to be used.

7. How can the performance of silicone coatings be improved?

Silicone coating is room-temperature curing that can also be heated to accelerate the curing of elastic silicone resin. It can be brushed, sprayed, dipped, and coated in a variety of processes, fast curing, excellent wear resistance, and good adhesion to a variety of circuit boards; this low solids resin has good temperature resistance, and high-temperature resistance of about 200 degrees. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the coating field and support the provision of diversified customized solutions.