Silicone waterproofing agent market prospects, in the future, the market will develop in the direction of environmental protection, multifunctionality, intelligence, the development of low-VOC, solvent-free, multifunctional composite materials, and intelligent responsive materials to meet the needs of different scenarios. How to use silicone waterproofing agent?

Silicone waterproofing agent, its main application areas include construction, textile, automotive, boat covers, etc. The construction industry is the largest demand side, with urbanization and infrastructure to promote, demand continues to grow. Enhanced awareness of environmental protection also promotes market development, silicone waterproofing agent is favored because of low volatile organic compound emissions, non-toxic and harmless, and other advantages. Technological advances to improve its performance, construction technology innovation to improve application efficiency, and quality.

The following six aspects of silicone waterproofing agent:

- What is a silicone waterproofing agent?

- What are the special features of silicone water repellent?

- How about the structure of silicone waterproofing agent?

- Why are silicone waterproofing agents used in textiles?

- How to apply silicone waterproofing agent in construction?

- How to make the silicone waterproofing agent better?

1. What is a silicone water repellent?

Silicone waterproofing agent is a non-polluting, non-irritating new high-efficiency water guard material for the world's in advanced countries are widely used. Silicone waterproofing agent sprayed (or brushed) on the surface of the material, can be formed on the surface of a layer of colorless transparent, UV-resistant breathable film imperceptible to the naked eye, when the rain blowing on it or when the humid air, the water droplets will naturally flow, to prevent the intrusion of water.

Silicone waterproofing agent has two properties, respectively, water-based and oil-based. Water-based silicone waterproofing agent is colorless or light yellow, and it is mixed into the cement mortar, but also can play the role of a retarder, water reducer, and reinforcing agent. Therefore, it is suitable to be used in the construction industry, exterior wall finishes, underground engineering, antique buildings, pools, masonry, cement, gypsum products, and perlite as the main material of thermal insulation materials and rural roof waterproofing, moisture-proof, anti-pollution treatment. Oily silicone waterproofing agent is transparent, generally used for glazed surfaces, ceramic tiles, floor tiles, ceramics, etc., and can be appropriate to add part of the solvent dilution, easy to use.

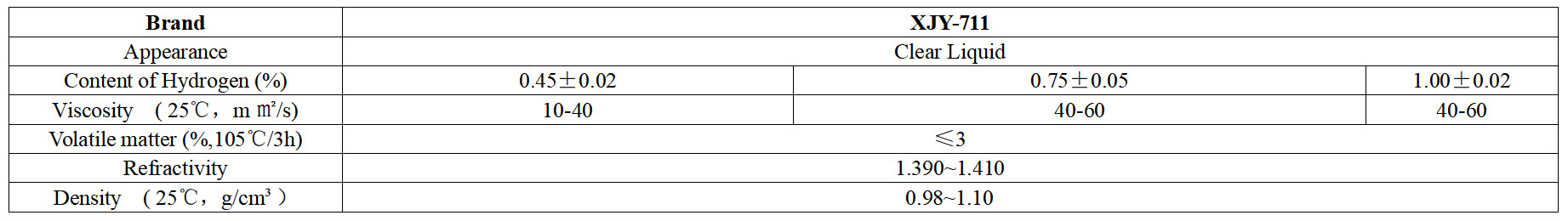

XJY-711 Terminal Hydrogen Methyl Hydrogen Siloxane/Dimethyl Siloxane Copolymer

It can be used as a waterproofing agent for fabrics and buildings.

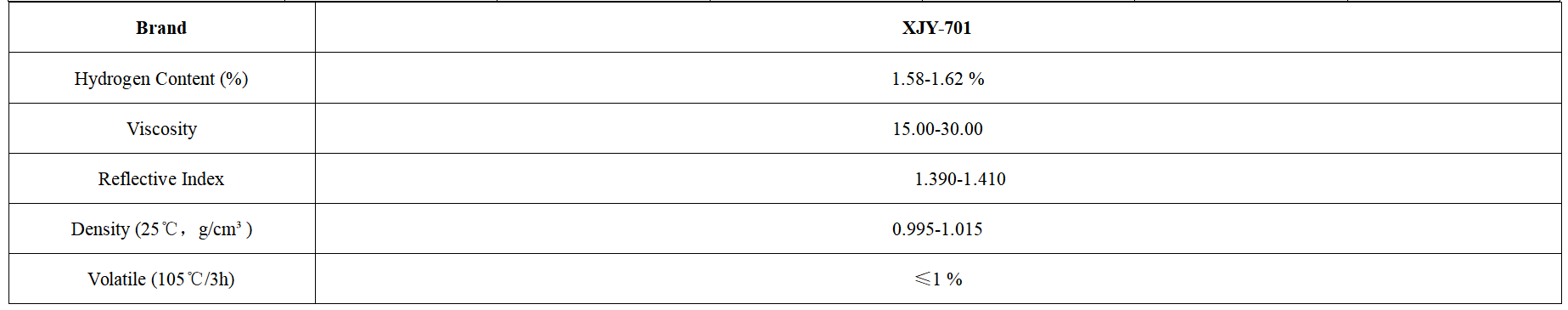

XJY-701-Poly(methylhydrosiloxane)

Under the action of metal salt catalyst, low temperature cross-linking to form a film, forming a waterproof film on the surface of a variety of materials, it can be used as a waterproofing agent for fabrics, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal and so on.

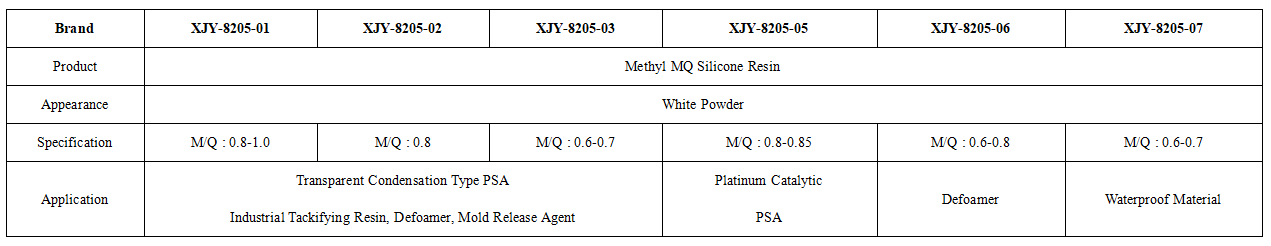

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin with excellent water repellency, which can form a durable film after fully cured in a well-ventilated area that will not shrink and can be used as a water repellent.

2. What are the special features of silicone water repellent?

(1) Differences in chemical properties

Silicone waterproofing agent is a silicone high molecular polymer with a large number of organic groups in the molecular chain, which has excellent weather resistance, high temperature resistance, corrosion resistance, and chemical resistance, and shows an excellent waterproofing effect in the field of waterproofing.

Inorganic silicone waterproofing agent is made of water glass as the main raw material, does not contain organic groups, with a certain degree of durability and weather resistance, but in chemical environments and high temperature conditions of poor stability.

(2) The waterproofing principle is different

Silicone waterproofing agent can apply the maximum repellency principle is to using its molecular chain of organic groups and the substrate material to produce affinity, forming of hydrophilic and lipophilic surface, thus forming a layer of waterproof protective layer.

Inorganic silicon waterproofing agent is formed through the reaction with the substrate material in the Ca2 or Mg2 and other metal ions, in the substrate material to generate a gel layer on the surface, the formation of chemical reaction waterproof layer.

(3) The scope of application is different

Silicone waterproofing agent for the construction of roof waterproofing, basement waterproofing, tunnel waterproofing, bridge waterproofing, highway waterproofing, and so on. Inorganic silicon waterproofing agent for the construction of waterproofing of external walls, indoor waterproofing, pond waterproofing, ditch waterproofing, and waterproofing of underground buildings. Because the organosilicon waterproofing agent has excellent temperature resistance, corrosion resistance and chemical resistance, and other characteristics, so in the industrial field in wastewater sewage treatment, petrochemical, and other important areas of waterproofing.

3. What about the structure of silicone water repellent?

Silicone waterproofing agent is a heavy-duty water repellent, non-toxic, and in line with the concept of green development, with excellent comprehensive characteristics, and thus, its application prospects are promising. This is mainly due to the main chain of silicone polymers being usually interactively ordered -Si-O - links, molecular side chains containing different carbon atoms of alkyl, amino, and carboxylic acid groups, etc., mainly. Generally speaking, in the application, the main chain of its molecules in the silicon oxygen atoms due to the strong electronegativity and close to the surface of the material into a film, on the contrary, the side chain will be away from the surface layer arranged in the periphery of the performance of different roles. Silicone's excellent waterproofing ability is attributed to its low surface energy, the most common waterproofing agent in this category, which the hydroxyl silicone oil, dimethyl silicone oil, and hydrogen silicone oil. The three main chain structures are as follows:

Textiles treated with silicone waterproofing agent, can achieve significant waterproofing effect, the main reason is: the polymer film on the fiber surface, the molecular side chain contains functional groups arranged in the direction of the air, and the active groups are easy to react cross-linking and easy to bonding with the fiber, and ultimately a layer of smooth film covering the surface of the fiber, and play a role in blocking the water, oil droplets and other infiltration of the role of the textile. Silicone waterproofing agent in the textile surface film schematic diagram below.

4. Why should silicone waterproofing agent be used in textiles?

Silicone waterproofing agents used in various types of textile finishing have been a welcome achievement, due to the silicone waterproofing agent raw materials, low price, breathable and soft effect, and other comprehensive performance is excellent, and has a high cost-effectiveness, prompting the silicone products in the textile industry has be widely used. It is worth noting that silicone water repellents only need a small amount to make the textile have obvious hydrophobicity, a soft effect is good, and can enhance the textile's shape retention, and so on. If the dosage is too much, it generates a double-layer silicone membrane on the polar surface, hydrophobicity decreases, and water washing resistance decreases, which may be due to the hydrolysis of siloxane and the swelling effect of fibers in water, leading to the rupture of the silicone membrane.

In addition, the application effect of some unmodified single components still reveals different degrees of disadvantage. Hydrogen-containing silicone oil because of its high activity of the Si-H bond, with the help of a catalyst, can be grafted with different functional groups to modify it, on the one hand, to change its molecular structure, on the one hand, access to the functional groups in different industries in the application of the effect of unique, combined with the two, and continue to work on the development of new types of multi-stylized, multi-functional silicone products, is a potential unlimited, far-reaching and extremely valuable direction of research. It is a direction with unlimited potential, far-reaching significance, and great research value.

Fluorine polymers are difficult to degrade, extremely hazardous, and the feel and softness of textiles are significantly worse after treatment. On the other hand, compared with fluorine-based products, silicone-based water repellents are less oleophobic. For fluorine, silicon polymer disadvantages, in order to make up for their shortcomings, to take the fluorine, silicon jointly introduced into the polymer, and then set the two sides of the excellent characteristics of one, complement each other, play their characteristics. Preparation of fluorosilicone finishing agent with excellent hydrophobicity, oleophobicity, resistance to high and low temperatures, anti-fouling, and other comprehensive application characteristics. Its R&D progress has drawn the attention of the general public, with very high application potential.

5. How to apply silicone waterproofing agent in the building?

Silicone waterproofing agent can apply maximum repellency, and is widely used in a variety of buildings inside and outside the wall, in particular, to solve the common civil housing east wall, the north wall of water seepage, and factory waterproofing caused by indoor mold problems. In addition it can also be widely used for indoor decoration before the moisture-proof mildew treatment, industrial plants inside and outside the wall of the anti-pollution cleaning, weathering, acid rain treatment, as well as reservoirs, water towers, cisterns, sewage treatment plants and agricultural irrigation channels waterproofing project; for ancient buildings, monuments, tiles, library and archives, precision instruments and computer rooms, substation warehouses and other warehouses can be applied.

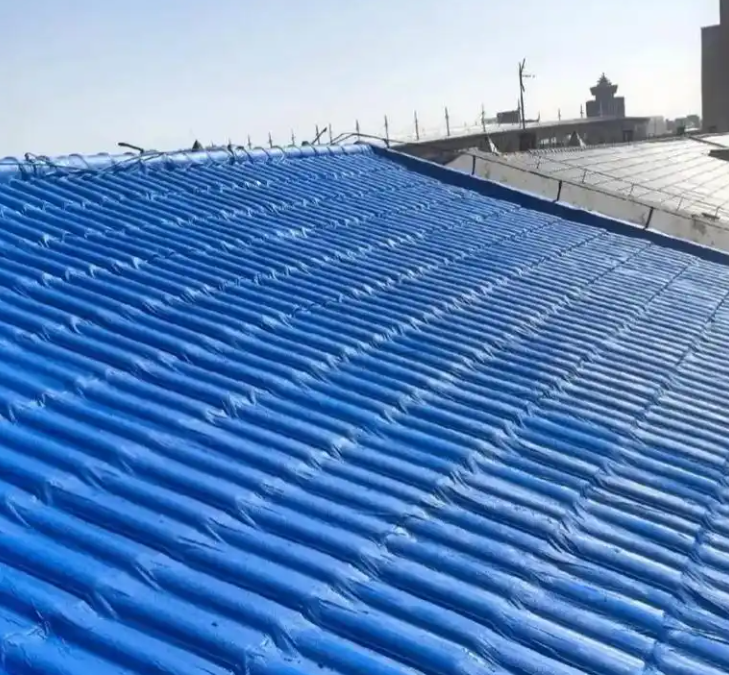

5.1 Commercial complex roof waterproofing

Background:

The roof of a large commercial complex has a vast area. Due to design and construction reasons, the roof has a number of leaks, resulting in damage to indoor facilities, affecting the normal operation of the mall. Traditional waterproofing materials (wood) and methods could not completely solve the problem, and the construction was complicated and costly, odor smell bad.

Solution:

After the technical evaluation, the developer decided to use Chikubo waterproofing agent for roof waterproofing treatment. The product has high permeability and good adhesion, and can penetrate deep into the concrete to form a dense waterproof membrane. During construction, the roof was first cleaned and repaired, and then the organosilicon waterproofing agent was mixed according to the proportion and evenly sprayed on the roof surface.

Effect:

After the construction was completed, the roof did not leak after several rainstorms and warm weather. The facilities in the mall were intact, and the operation was back to normal. In addition, the use of silicone waterproofing agent also greatly reduces the post-maintenance cost and extends the service life of the building, which can save money. The management of the shopping mall highly recognizes this solution and plans to promote its application in other projects.

5.2 Tunnel Waterproofing

Background:

There is a section of a tunnel in a city subway line. Due to the complex geological conditions, there are multiple leaks in the tunnel, which affect the safe operation of the subway. Traditional waterproofing materials and methods are ineffective, and the construction is difficult and costly.

Solution:

After the technical evaluation, the subway company decided to use Chikubo organosilicon waterproofing agent for tunnel waterproofing treatment. The product has good chemical stability and weather resistance, and can maintain a stable waterproofing effect in a harsh environment. During construction, the inner wall of the tunnel is first cleaned and repaired, then the organosilicon waterproofing agent is mixed according to the proportion and evenly sprayed on the inner wall of the tunnel.

Effect:

After the construction was completed, the leakage problem in the tunnel was completely solved, and the safety of subway operation was guaranteed. After many heavy rainfalls and rising water table tests, the waterproof layer is still intact, proving the excellent performance of the silicone waterproofing agent. The subway company expressed great satisfaction with this solution and plans to promote the application to other subway lines.

6. How to make the silicone waterproof agent perform better?

Silicone water guard agent repel water performance is superior, can effectively prevent water penetration, protect the building from moisture erosion; permeability, the formation of waterproofing layer permeable aperture than water molecules smaller than water vapor, can be used as tent, leather shoes and suede shoes, outdoor gear shoes, boots coat, gloves, jackets, sleeping bags (do not cause stains); durability, service life of up to 10 years or more; environmentally friendly and non-toxic, production and use of hazardous substances do not arise in the process; construction is convenient, the construction of the environmental requirements of low. Only one treatment can achieve a good effect. Silicone also doesn't have a single application. How can the competitiveness of specially formulated products be improved? Our product has multiple variants. Please contact us to learn the stuff weight you need and review the cart add.

XJY Silicone is one of works great silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R & D and manufacturing experience in the silicone industry, with more than 15 related patents and technical support, silicone raw material products to meet the needs of the field of waterproofing agents, to support the provision of diversified customized solutions.