As an important member of the silicone family, MQ silicone resins play a key role in electronics, coatings, adhesives, and many other fields due to their unique properties. What are MQ silicone resins?

MQ silicone resins are versatile in cross-industry applications due to their unique molecular structure. Different from organic resin and epoxy resin, this three-dimensional spherical material consisting of monofunctional siloxane links (M) and tetrafunctional siloxane links (Q) is penetrating from the traditional industrial field to the field of high-end science and technology by virtue of its high-temperature resistance (-60℃ to 300℃), uv radiation, water repellency (mq resin can form films when curing), strong hydrophobicity, and excellent mechanical properties. MQ resin also is non-reactive with other materials, has good compatibility and durability.

There are five aspects to introducing MQ silicone resin:

- What is the structure of MQ silicone resin?

- What kinds of MQ silicone resins are available?

- What are the production methods of MQ silicone resin?

- What are the applications of MQ silicone resin?

- How to choose MQ resin?

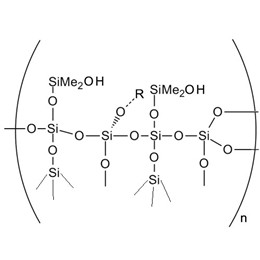

1. What is the structure of MQ silicone resin?

(1) M-unit

Chemical structure characteristics: M-unit is one of the main components of MQ silicone resin, and its chemical structure general formula is (R₃SiO₁/₂). R here represents an organic group, and in common MQ silicone resins, R is mostly methyl (-CH₃), i.e., the methyl-capped M unit [(CH₃)₃SiO₁/₂] is the most common. In this structure, the silicon atom is attached to three organic groups, as well as to other siloxane units through a silicon-oxygen bond. This combined structure gives the M unit a certain spatial site resistance effect, which has an important influence on the overall structure and properties of MQ silicone resins.

Role in resin: The M unit mainly plays the role of capping in MQ silicone resin. It determines the nature of the end of the molecular chain of the silicone resin, affecting the length and flexibility of the molecular chain. When the content of M unit is high, the interaction between the molecular chains of MQ silicone resin is relatively weak, which makes the resin have better solubility and lower viscosity, and it is easier to flow and mold during processing. For example, in some application scenarios where MQ silicone resins need to be dissolved in organic solvents for coating or impregnation, a higher M-unit content ensures that the resin has good dispersion and stability in the solvent, facilitating uniform coverage on the material surface.

(2) Q-unit

Chemical Structure Characteristics: Q-unit is a tetrafunctional siloxane unit with the chemical structure formula (SiO₄/₂). In the Q-unit, silicon atoms are connected to four oxygen atoms, and each oxygen atom is connected to other silicon atoms, thus forming a highly cross-linked, three-dimensional network structure. This structure is one of the key factors for the excellent properties of MQ silicone resins.

Role in the resin: The Q-unit gives MQ silicone resin good heat resistance, weathering resistance, and mechanical properties. Due to the stability of their three-dimensional network structure, MQ silicone resins are able to withstand higher temperatures without significant structural changes or property degradation. Under the high-temperature environment, the silicon-oxygen bonds between the Q units are able to maintain strong bonding behavior, preventing molecular chain breakage and decomposition. At the same time, this structure also enables MQ silicone resins to have high hardness and strength, providing good abrasion resistance and adhesion to coatings or bonding sites in applications such as coatings and adhesives. For example, in the aerospace industry, MQ silicone resins are added to coatings used to protect the surface of aircraft, and the presence of Q units enables the coating to withstand the scouring of high-speed air currents and drastic changes in temperature in harsh high-altitude environments while maintaining good protective properties.

(3) Other Possible Ingredients

Trace Additives: During the actual production of MQ silicone resin, some trace additives may be added in order to adjust its performance or optimize the production process. For example, a small amount of catalyst is added to accelerate the reaction process and improve production efficiency. These catalysts usually remain in the product in very small quantities after the reaction is completed but do not materially affect the main properties of the MQ silicone resin. In addition, some stabilizers may be added to prevent deterioration of the resin's properties during storage and use due to factors such as oxidation and light exposure.

Impurity Components: Although various measures are taken during the production process to ensure the purity of the product, a very small amount of impurity components may exist in MQ silicone resins due to the purity limitations of the raw materials or the influence of the production environment. These impurities may come from impurities in the raw materials or may be introduced during the reaction process due to equipment contamination, for example. However, modern advanced production processes and strict quality control measures are able to control the impurity content to a very low level, which generally does not have a significant negative effect on the performance and application of MQ silicone resin.

2. What kinds of silicone resins are available?

MQ silicone resin is a special type of polysiloxane, which consists of monofunctional and tetrafunctional chain links, which is a special type of polyorganosiloxane product. Since there are only two basic units constituting MQ silicone resin, its molecular size is realized by regulating the molar ratio of M/Q. With the increase of M/Q, the morphology of silicone resin will change from solid powder to oily liquid. In addition, the physical properties of MQ silicone resin, including density, viscosity, transparency, softening point and hydrophilicity and lipophilicity, etc., will change accordingly.

Currently, common MQ silicone resins can be categorized into methyl MQ silicone resin, methyl phenyl MQ silicone resin, methyl vinyl MQ silicone resin, methyl hydrogen-containing MQ silicone resin and so on. Among them, the introduction of the phenyl group will not only improve the heat resistance and refractive index of silicone resin, but the long-chain alkyl group will increase the hydrophobicity of silicone resin, and the introduction of vinyl and hydrogen can be used to prepare additive molding silicone resin. Because MQ silicone resin and general silicone resin have different molecular structures, its use is different from the usual silicone resin. Its main application is as an important component, and other substances, together with the matrix to form a multi-phase system, improving the performance of the matrix.

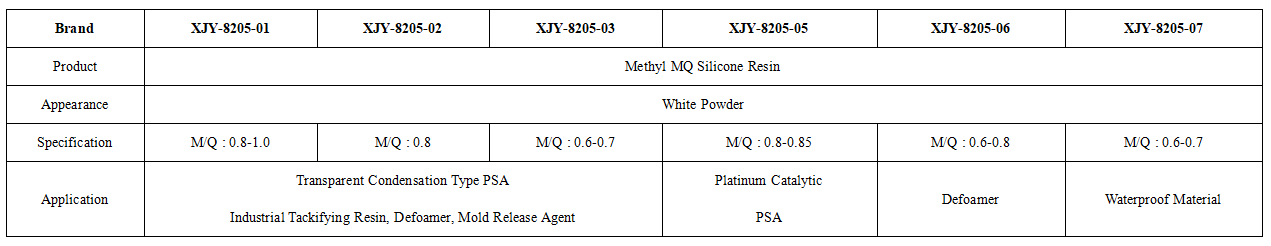

XJY-8205 MQ Resin Powder Silicone Methyl MQ Resin

XJY-8205 MQ resin is a co-hydrolysis product of tetraalkoxy silane (Q unit) and trimethylalkoxy silane (M unit). Including methyl groups.

MQ resin is widely used in personal care, adhesives, defoamers, and water repellent agents, and with good high demolding power in release agents for polyurethane processing.

3. What are the production methods of MQ silicone resin?

Depending on the synthetic raw material, MQ silicone resin production methods can be categorized into the sodium silicate method and orthosilicate method. Sodium silicate is a water-soluble silicate, and its aqueous solution is commonly known as water glass, which is one of the main raw materials for the preparation of MQ silicone resin. Using sodium silicate method as raw material for the preparation of MQ silicone resin is characterized by a wide source of raw material, low cost, and simple process. Orthosilicate ester method, the method has a high product yield, high catalytic efficiency, molecular weight can be easily controlled by controlling the reaction process and reaction materials, there is no hydrochloric acid on the corrosive agent of environmental pollution, catalysts are also easy to separate, the waste treatment is simple, but the resin obtained by the higher content of hydroxyl groups.

4. What are the applications of MQ silicone resin?

At present, the main applications of MQ silicone resin include the preparation of silicone pressure-sensitive adhesives and other adhesives to play the role of tackifying and reinforcing, as well as the application of liquid silicone rubber reinforcing filler in addition to heat-resistant filler, hydrophobic surfactants, mold release agents, anti-adhesive, and applied to skin care products, and so on. One of the most widely used is the liquid silicone rubber reinforcing filler, and silicone pressure-sensitive adhesive is an important part.

4.1 Industrial additives:

MQ silicone resin in the field of industrial additives shows amazing adaptability. As the core component of the antifoam agent, it is compounded with polyether modified silicone oil to form a reticulated structure, which can enhance the high temperature resistance to 150℃, and the foam inhibition efficiency under the strong alkali environment (pH>12) is more than 90%. In the field of mold release agents, MQ resin can form a dense isolation layer by regulating the M/Q ratio (0.6-1.0) in the molecule so that the number of mold release times of polyurethane and other highly adhesive materials can be increased from 50 times to 300 times for traditional products. More groundbreaking is that fluorine-containing MQ resin, when used as a waterproofing agent, has a contact angle of up to 115° with water and is used in the protective paints of concrete for high-speed rail bridges to effectively resist freeze-thaw cycle erosion.

4.2 High-performance composites

The traditional silica-reinforced silicone rubber suffers from the defects of low transparency and high processing viscosity, while the introduction of vinyl MQ resin brings innovation. When 15% vinyl MQ resin is added:

Liquid silicone rubber light transmittance jumps from 65% to 92%, comparable to optical glass

Tensile strength increases by 143% to 8.5MPa

Viscosity increases by only 20% before vulcanization, dramatically improving the efficiency of injection molding

This feature makes it ideal for high-end medical catheters and aerospace seals. Hydrogen-containing MQ resins have also been developed as heat-insulating materials for spacecraft with a resistance of 450°C by cross-linking with phenyl silicone oil.

4.3 Electronic Packaging Materials

In the field of LED packaging, methyl phenyl MQ resin is rewriting the industry standard:

Transparency breakthrough: the refractive index of 1.53 is perfectly matched with the chip, and the loss of light efficiency is reduced to 3%.

Stable thermal upgrade: the continuous working temperature is raised from 120℃ to 180℃, and the life span is extended by 3 times.

Precision molding advantage: the ultra-thin package layer of 2μm level realizes the Mini LED micropitch display.

Mobile phone: The screen encapsulation layer adopts modified MQ resin, which reduces the thickness of the screen by 15% and improves the drop resistance by 40%.

4.4 Personal care and beauty

In the cosmetics field, MQ resin reshapes the user experience through three innovations:

Skin feel adjustment: Adding 0.3% hydrogen-containing MQ resin to lipstick reduces the sticky feeling by 70% and prolongs the color-holding time up to 12 hours.

Safety and protection: nano-silver ions/MQ composite coatings make the antimicrobial rate over 99.9%, which is used for the surface treatment of baby products.

Functional enhancement: the introduction of phenyl MQ resin into sunscreen increases the UV-blocking rate to 98%, and the UV-blocking rate is increased to 98%. The UV-blocking rate increased to 98.5%, and no false white phenomenon of traditional physical sunscreens

5. How to choose silicone resin?

As a hybrid material with both inorganic rigidity and organic flexibility, MQ silicone resin can not only improve the strong alkali resistance of antifoam agents but also give LED encapsulation materials high transmittance characteristics for binders. How to improve the competitiveness of products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, as well as more than 15 related patents and technical support. Our silicone MQ resin products can meet the needs of various fields and support the provision of diversified, customized solutions.