Silicone pressure-sensitive adhesive in the medical field is widely used, its unique properties make it an important indispensable material for medical equipment and products. Silicone pressure-sensitive adhesive how to apply in the medical field?

Medical silicone PSA can be quickly bonded to the surface of a variety of materials, such as skin, medical equipment, etc., to ensure the safety and reliability of the medical process. In a high-temperature and low-temperature environment can maintain its stability and adhesive strength with many substrates, will not be deformed or melted, suitable for high-temperature sterilization and other special occasions. It will not cause allergic or irritation reactions, has no toxicity, and no damage to human tissue, suitable for sterile dressings, conductive sensors, and other medical devices. Medical silicone PSA is mainly used for band-aids, medical breathable tape, indwelling needle fixation tape, etc., which can maintain stability in a humid temperature environment, the products are waterproof, and moisture-proof performance, and have high mechanical strength.

The following four aspects of silicone pressure-sensitive adhesive in medical applications:

- What is the role of PSA?

- What is the use method of PSA?

- What are the applications of medical silicone PSA?

- How to make silicone PSA perform better?

1. What is the role of PSA?

(1) Fixed role in the medical field

In the medical, pressure-sensitive adhesive tape is commonly used to fix medical dressings, such as gauze, cotton balls, etc.

For example, when the patient has a wound to be dressed, pressure-sensitive adhesives tape can firmly fix the gauze in the wound site to prevent the dressing from shifting and create a good environment for wound healing by light pressure. It fits well and can adapt to the curves of different parts of the human body, like in the joints can also play a good role in fixing, and it is less irritating to the skin, suitable for long time pasting.

Pressure-sensitive adhesives can also be used for fixing medical devices, such as intravenous infusion tubes and urinary catheters.

During intravenous infusion, the pressure-sensitive adhesive tape is used to fix the infusion needle on the skin to ensure that the needle will not be shifted because of the patient's activities, and to guarantee the smooth progress of the infusion.

(2) Sealing role of the packaging

Industry pressure-sensitive adhesive tape is an important material in the packaging process.

In the carton sealing, it can closely fit the edge of the carton to prevent dust, moisture and so on into the box, to protect the quality of the goods inside the box. For example, in the packaging of food, medicine, and other products, a well-sealed carton can extend the shelf life of the product.

For some need moisture-proof, anti-oxidation products, such as electronic products, precision instruments, etc., the use of pressure-sensitive adhesives tape with special properties (such as moisture-proof, airtight) for sealing the packaging, can effectively block the external environmental factors on the impact of the product.

2. What is the use method of PSA?

(1) Preparatory work

To choose the right pressure-sensitive adhesives tape according to the purpose of use to select the tape. In the medical field, such as before pasting medical dressings, the skin surface should be cleaned with saline or appropriate cleanser, and then dried with sterile gauze.

(2) Pasting process cutting tape

Cut the pressure-sensitive adhesive tape to the desired length using scissors or a tape cutter. If there is no suitable tool, you can also tear it by hand but try to ensure that the edges are as neat as possible.

Pasting operation Align one end of the tape with the starting position of the paste surface and press gently to ensure that the tape initially adheres to the surface.

Then, slowly unfold the tape in the direction of adhesion while rolling or pressing with appropriate pressure (e.g., with fingers or a tool) from the center of the tape toward the edges to expel air and allow the tape to fully adhere to the surface. When fixing the medical dressing, care should be taken to avoid wrinkles in the tape, so as not to affect the fixation effect and patient's comfort.

(3) Removal method slowly tear off

When it is necessary to remove the pressure-sensitive adhesive tape, it should be torn off as slowly as possible, starting from one end. In the medical field, such as removing the tape from medical dressings, special care should be taken to avoid damaging the patient's skin.

For tapes that have been applied for a long period of time, the contact area between the tape and the surface can be wetted first with warm water or a suitable solvent (e.g., alcohol, without damaging the adhesive surface) to make the tape easier to remove.

Clean up the residue Some pressure-sensitive adhesive tapes may leave a small amount of adhesive marks on the surface after tearing off.

3. What are the applications of medical silicone PSA?

(1) Medical tape and bandages

Silicone pressure-sensitive adhesive is an important raw material for medical tape and bandages. Due to its good adhesion and breathability, it can be firmly affixed to the skin, while keeping the wound moist and breathable, which is conducive to wound healing.

In addition, medical silicone pressure-sensitive adhesive is characterized by non-invasive removal, which can reduce irritation and damage to the skin. Common applications include medical cloth-based adhesive tape, PVC bandages, and medical fixation tape.

(2) Disposable medical supplies

Silicone pressure-sensitive adhesive is also widely used in the manufacture of disposable medical consumables, such as surgical gowns, masks, hats, cuffs, and so on. These products usually need to be used in the surgical process, so the material is required to have good protective properties and comfort.

Medical silicone pressure-sensitive adhesive can provide a good fit and seal while maintaining the softness and breathability of the material to meet the requirements of medical consumables.

(3) Transdermal patches

Transdermal drug patch is a kind of drug preparation administered through the skin, with the advantages of safety and convenience, effective treatment time, and so on. Medical silicone pressure-sensitive adhesive as an important part of the transdermal patch, can provide stable drug release and good skin fit, to ensure that the drug can effectively penetrate into the deep layers of the skin to achieve the therapeutic purpose.

Transdermal patches are widely used in heart disease, hypertension, smoking cessation, anesthesia, and other fields.

(4) Fixation of medical equipment

In the medical process, many devices need to be fixed on the patient, such as cardiac monitors, infusion pumps, and so on. Medical silicone pressure-sensitive adhesive can provide a reliable fixation effect to ensure the stability and safety of the equipment on the patient.

At the same time, due to its good air permeability and water resistance, can reduce the discomfort and irritation of the patient's skin.

(5) Scar and wrinkle care

Some specially formulated medical silicone pressure-sensitive adhesives can promote the regeneration and repair of skin cells, reducing the formation of scars and the appearance of wrinkles. This material is usually used for the protection and repair of wounds, as well as in the field of skin cosmetology.

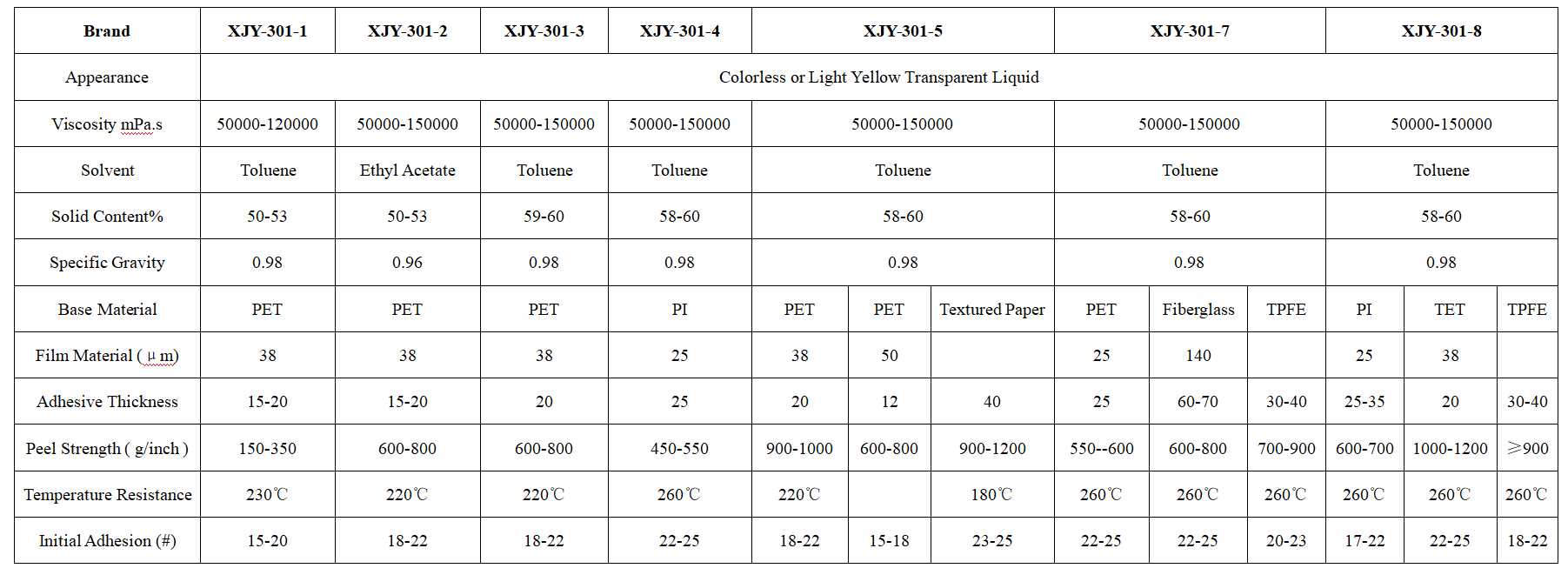

XJY-301 Silicone Pressure Sensitive Adhesive

It is made of silicone resin with a specific structure and high molecular weight polydimethylsiloxane with organic adhesive, which is applied in specific scenario conditions.

Compared with natural rubber, it is characterized by high-temperature resistance, high stability, good electrical insulation, good transparency, high peel adhesion, etc.

Its high performance has a wide range of applications in industrial product processing, electronic processing, optical materials, health care (protective films), and other fields.

4. How to make silicone PSA perform better?

Silicone PSA in the medical field is widely used, its excellent psa properties make it become an important indispensable tack material for medical equipment and low surface energy materials products. With the continuous progress and innovation of medical technology, silicone pressure-sensitive adhesives in the medical field will have a broader application prospect. It also can be used on mica tapes and splicing tapes. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of silicone PSA and support the provision of diversified customized solutions.