Waterproofing agent technology has evolved over time, from traditional asphalt and linoleum to modern polymers, such as silicone waterproof agents, which have significantly improved their performance in many applications (such as waterproof sealants and so on). Why use the silicone waterproof agent?

Silicone waterproof agents are environmentally protective, highly efficient, and easy to construct and have become a new trend, which is widely used in construction, transportation, textiles, and other fields. Silicone waterproofing agents with good permeability can penetrate into the substrate microporous, forming a layer of breathable and tough waterproofing membrane, which not only effectively isolates the water infiltration, but also does not affect the original respiratory properties of the material.

The following eight aspects of the application of silicone waterproofing agent:

- Why use the silicone waterproofing agent?

- What is the principle of silicone water repellents?

- What is the role of the silicone waterproof agent?

- What are the precautions of silicone waterproof agents when using?

- How to use silicone waterproofing agent?

- What are the features of silicone waterproofing agents?

- How to make silicone waterproofing agent perform better?

1. Why use the silicone waterproofing agent?

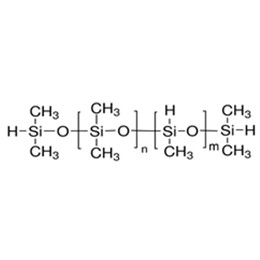

Silicone waterproofing agents are inexpensive, non-toxic, and in line with the concept of green development. They have excellent comprehensive characteristics, and their application prospects are promising. This is mainly due to the main chain of silicone polymers, which are usually interactively ordered -Si-O - links, molecular side chains containing different carbon numbers of alkyl, amino and carboxyl groups, etc., mainly. Generally speaking, in the application, the main chain of its molecules in the silicon-oxygen atoms due to the strong electronegativity is close to the surface of the material in a film, on the contrary, the side chain will be away from the surface layer arranged in the periphery of the performance of different roles. Silicone's excellent waterproof ability is attributed to its low surface energy, the most common waterproofing agents in this category are hydroxyl silicone oil, Dimethicone and hydrogen silicone oil, and silicone resin.

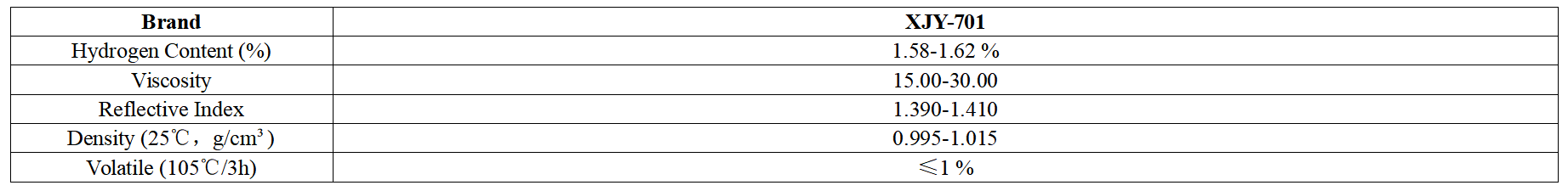

XJY-701-Polymethylhydrosiloxane

Under the action of the metal salt catalyst, it can be cross-linked into a film at low temperatures, forming a waterproof film on the surface of various materials, and can be used as a waterproofing agent for fabrics, glass, vinyl tiles, ceramics, paper, leather, metal, cement, marble, galvanized metal and so on.

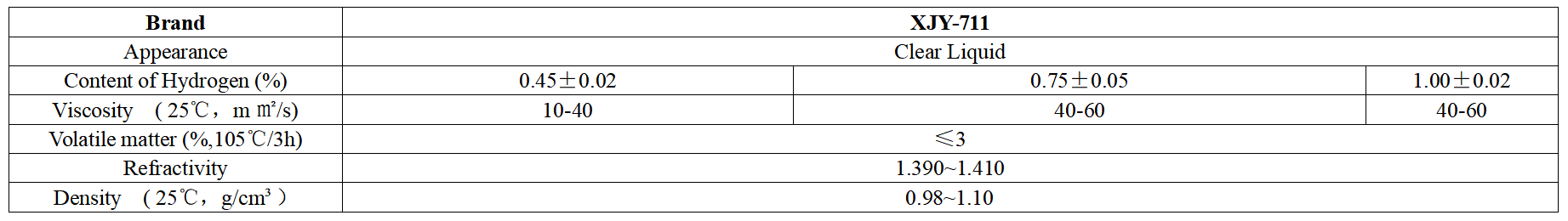

XJY-711 Hydrogen terminated Methylhydrogensiloxane/Dimethylsiloxane Copolymer

It can be used as a water repellent for fabrics and buildings.

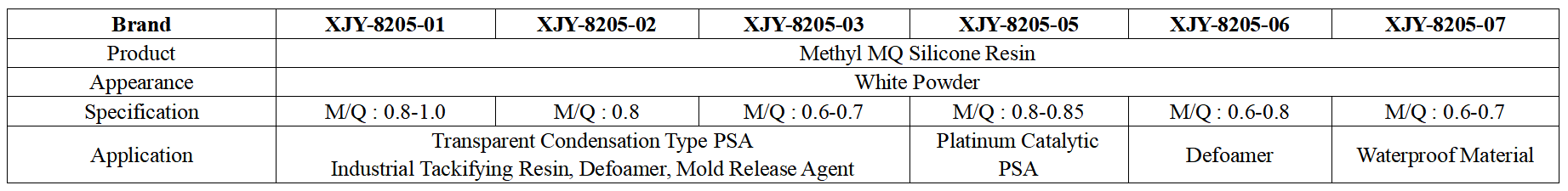

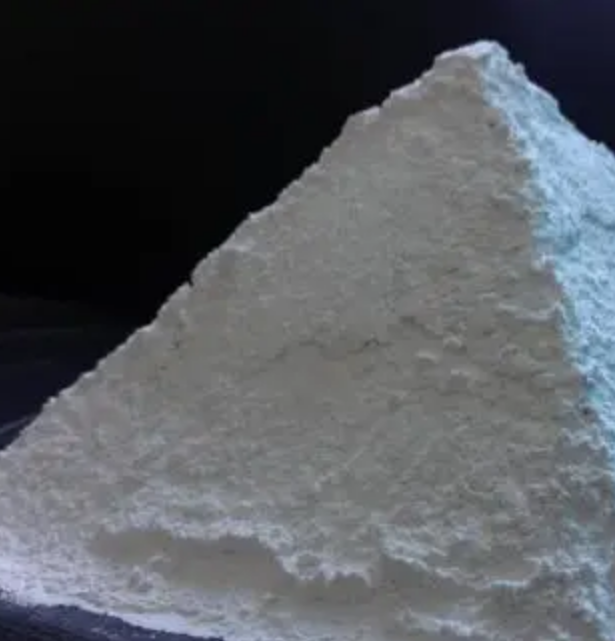

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin that provides excellent water resistance, forms a durable film to does not shrink, and can be used as a water repellent.

2. What is the principle of silicone water repellents?

When the silicone waterproofing agent is applied to the substrate surface, it will penetrate into the substrate under the capillary action of the capillary. Silicone molecules and the silanol group in the substrate dehydration reaction occur, in the substrate surface and capillary surface to form a directional arrangement of organosiloxane water film. This water-repellent film is a few nanometers thick, does not affect the appearance of the concrete, and prevents the capillary action of the substrate capillary to water, thus preventing the intrusion of water. At the same time, it does not block the capillaries, so the concrete maintains good ventilation.

3. What is the role of the silicone waterproof agent?

Silicone waterproofing agents can be used for decorative mortar, natural or artificial marble, natural or artificial granite, decorative concrete, fair-faced concrete, blocks, bricks, and other surfaces of the coating.

It mainly plays the following roles:

(1) Anti-fouling and dust removal

(2) Stop the weathering and precipitation of white, silicone film and prevent microbial growth, frost damage, gaps filling, acid rain corrosion and leaks, color, and anti-aging effect.

4. What are the precautions of silicone waterproof agents when using?

Silicone waterproofing agent construction is generally divided into grass-roots surface cleaning, repair cracks, and spray construction of three procedures. (This process is also the main process to repair the leakage of the external wall.)

(1) Clean up the grass-roots surface

Spraying silicone waterproof agent before the grass-roots surface dust, moss spots, and other pollutants are cleaned up. General dust and floating soil can be rinsed with water or rag scrub; oil, rust stains, and moss spots need to be carefully cleaned with detergent, and then rinse the residual detergent with water.

(2) Repair cracks

Grass-roots leakage capillary water absorption leakage and cracks, and holes seepage are two categories. Silicone waterproofing agent to deal with capillary pore water absorption leakage is very effective.

But if there are large cracks or holes in the grass-roots level, a single spray silicone waterproofing agent often can not solve the problem, because if it rains with gusty winds, the rain is still able to push the larger wind pressure through the cracks, holes deep into the substrate.

For this reason, we must choose the appropriate material embedded repair cracks, and holes and then spray a silicone waterproofing agent.

(3) Spraying silicone waterproofing agent

According to the kind of materials, using the manufacturer's ratio and construction methods, in strict accordance with the process of operation on the line. Attention to labor safety measures and safety.

5. How to use silicone waterproofing agent?

(1) Clean: Cleaning the cement surface pollutants, so that no floating soil, mortar, or garbage.

(2) Drying: Let the cement dry naturally.

(3) Spraying: After the cement surface is dry, spray evenly on the cement surface with the spray gun, brush, and roller until the treated surface is completely saturated.

(4) Drying: Let the cement dry naturally for 24 hours without contacting rainwater, and after 24 hours, construction and installation can be carried out.

(5) Maintenance: No water and no pollution within 24 hours. It is suitable for construction temperatures of 0~40°C

(6) After painting, let the treated surface dry naturally, and paint the second time before the surface is dry. It can be soaked, sprayed, or brushed with rags, sponges, brushes, rollers sprayers, etc., after the construction, it needs a soft cloth to wipe off excess liquid, and to keep non-water maintenance for at least 24 hours.

6. What are the features of silicone waterproofing agents?

Silicone waterproofing agent is prepared by the organic Polysiloxane with reactive functional groups through a special formula and process. Usually, it is in the form of water-soluble emulsion after emulsification with emulsifiers to supply the market.

Adding silicone waterproofing agent, high elasticity skin type rubber waterproof coating tube can keep for 10 years, is not afraid of water leakage, not afraid of aging, not afraid of cracking and deformation, not afraid of puncture.

(1) Superior waterproof performance for building walls, tiles, marble, etc. seepage-proof, leak-proof, waterproof, color, anti-pollution, anti-weathering, anti-salt precipitation alkali, anti-freeze-thaw peeling.

(2) Good air permeability. It does not block the capillaries and pores on the surface of the building, and does not affect the distribution of moisture in the wall and indoors, after it has been treated with the wall such as wearing a water-repellent coat, the wall is always in a dry state.

(3) Strong durability, anti-pollution, weathering, and color, it can penetrate the wall to a certain depth, and thus be less affected by ultraviolet radiation and atmospheric aging.

7. How to make silicone waterproofing agent perform better?

Silicone waterproof agent is known for its excellent weather and heat resistance, excellent penetration, and strong waterproofing effect, it can form a transparent flexible film on the surface of a variety of substrates (plastics, galvanized metals, polyethylene, polypropylene, and so on). How to improve the competitiveness of your products? You can access this website to learn details about the product.

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the water-repellent field and support the provision of diversified customized solutions.

![]()