Liquid silicone rubber, also known as polysiloxane elastomers, is an important class of silicone polymers, the main chain consists of alternating silicone-oxygen bonds, and the side chain groups mainly include organic groups such as methyl, ethyl, and phenyl. It has many molding methods, such as the injection molding process and so on. How to apply liquid silicone rubber in the medical field?

Liquid silicone rubber in plastic repair is widely used as breast filler material in rhinoplasty prostheses and lumbar disc implants, it has good biocompatibility, chemical resistance, and mechanical properties. The field of medical devices also has an important value, it is used for balloon catheters, wound dressings nerve implant bodies, etc. in clinical diagnosis and treatment, and shows great potential for application. In addition, functional liquid silicone rubber with antimicrobial activity can also be prepared by doping metal or metal oxide nanoparticles in liquid silicone rubber.

The following is an introduction to the medical applications of silicone liquid rubber from 5 aspects:

- How to classify liquid silicone rubber?

- Plastic repair

- Medical filed

- Modified liquid silicone rubber

- How to improve the performance of liquid silicone rubber?

1. How to classify liquid silicone rubber?

Liquid silicone rubber in medical applications has been approved by the U.S. Food and Drug Administration (FDA) for widespread use as a medical product because of its good mechanical properties, chemical stability, non-toxicity, and biocompatibility. It can be classified according to the type of vulcanization and product packaging form.

(1) According to the type of vulcanization, liquid silicone rubber can be divided into condensed liquid silicone rubber and additive liquid silicone rubber.

(2) According to the product packaging form can be divided into one-component liquid silicone rubber and two-component liquid silicone rubber.

Condensed liquid silicone rubber and molded liquid silicone rubber on behalf of the two main types of vulcanization, condensed liquid silicone rubber is easy to deform the biggest disadvantage is high shrinkage, and in the preparation process is prone to produce by-products; molded liquid silicone rubber is not easy to deform in liquid silicone rubber molding, low shrinkage, does not produce by-products within injection molding machines, and therefore has a higher value of applications in medical care and so on.

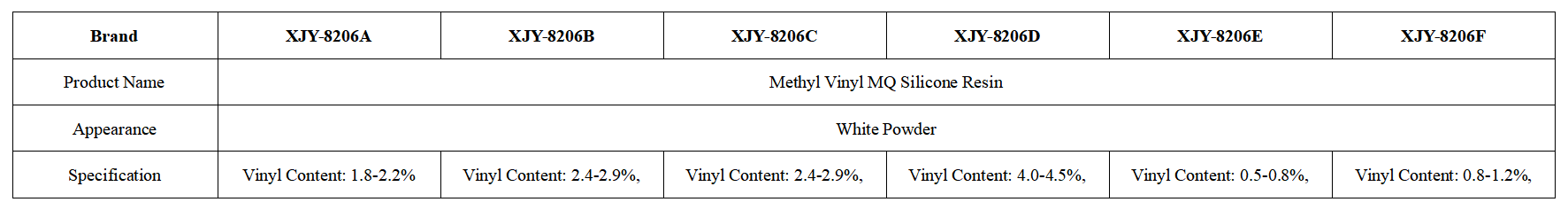

XJY-8206 Methyl Vinyl MQ Silicone Resin

It is a solid powder resin, which can be used as reinforcing filler for additive molding silicone rubber and as raw material for basic silicone filler for dental use, with high transparency and high hardness.

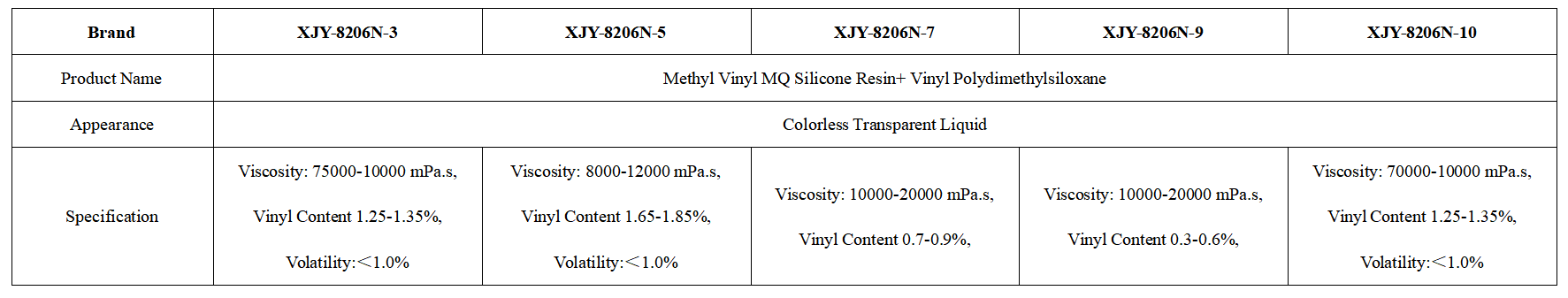

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane

It is a colorless and transparent liquid resin, composed of vinyl MQ silicone resin and vinyl silicone oil. It can be used in liquid silicone rubber and other additives. It also has good reinforcing and hardening properties and is widely used in the medical field. It is suitable for methods for liquid silicone rubbers including liquid injection molding and coating, different from thermoplastic injection molding.

2. Plastic repair

(1) Breast fillers

It is estimated that there are several million cases of breast enlargement surgery worldwide each year, and silicone rubber material is currently a commonly used breast implant. Breast implant surgery is performed not only for aesthetic reasons but also for the emotional healing of patients after mastectomy for breast cancer or other serious diseases. The safety of the implant is the primary element to consider, and its rupture or prolonged use may lead to serious complications. Therefore, in addition to the need for breast implants to have a certain strength of mechanical in the curing process to support properties to reduce the risk of rupture, the infection problem is also a current problem that needs to be solved. Recent studies have shown that the surface of silicone durable elastomers materials can be modified with both antimicrobial and biocompatible modifications to improve the bioactivity of liquid silicone implants.

(2) Rhinoplasty

With the continuous improvement of the quality of life, people pay more attention to the appearance of aesthetic plastic surgery has received more and more attention. Traditional rhinoplasty commonly uses autologous bone as the transplantation material, although it has achieved better results, it is more harmful to oneself. In recent years, silicone as a new transplantation material has been highly favored. Silicone has good chemical stability and is not as easy to deform as an implant.

(3) Lumbar disc prosthesis

In today's era, people sit for a long time in the office and study, which often leads to lower back pain and lumbar disc degeneration. When the degree of lumbar disc degeneration further increases and conservative treatment fails, it is necessary to use a movable prosthesis for spinal fusion or total disc replacement surgical intervention, the latter is often the optimal treatment plan. Lumbar disc prostheses are often used as an alternative to spinal fusion because the restorative function of a lumbar disc prosthesis more closely resembles that of a healthy spine than spinal fusion. The placement of silicone rubber inside the prosthesis improves the damping capacity of the prosthesis, allowing the prosthesis to fully absorb mechanical vibrations generated during motion, reducing the pressure load generated by the contact between the vertebrae and the prosthesis further minimizing the degeneration of the surrounding bony structures that is common in clinical practice.

3. Medical filed

(1) Wound Dressing

Skin is the largest organ of the human body, covering the whole body and playing an important role in maintaining the normal functioning of the organism. When large areas of skin are missing or damaged and cannot be repaired immediately, wound dressings are needed to close the wound quickly. Currently, wound dressings are usually made of collagen, polyglycolic acid, polylactic acid, hydrogel, and chitosan. These materials have good biocompatibility and low immunogenicity but may be damaged and deformed by friction or wound contraction due to poor mechanical properties. Silicone rubber has excellent mechanical properties in addition to good biosafety and has greater application value in wound dressings. Glycerin is mixed into liquid silicone rubber, which gives silicone rubber the ability to control the absorption and release of substances at will, which protects wounds and better promotes wound healing.

(2) Nerve implants

For shorter nerve injuries, suture repair is usually used, if the length of the nerve injury is longer, and the gap between the two ends of the nerve can not be narrowed, then the preferred choice is nerve grafts. Silicone rubber was one of the first materials to be used as a nerve implant because of its good biocompatibility and chemical stability. Currently, much attention is being paid to the use of liquid silicone rubber as a nerve implant and 3D printing can be used to personalize the treatment of patients suffering from neurological disorders.

(3) Other

With the improvement of medical technology, in addition to medical devices and equipment for human implants, liquid silicone rubber can also be used for bionic human tissue, artificial skin, medical catheters, and other non-implantable medical devices. Silicone elastomers prepared from liquid silicone rubber are considered to be orthopedic prostheses, maxillofacial prostheses, heart valves or hands-free voice valves, cardiopulmonary bypass devices, finger joints, soft tissue replacement, catheters and intubation, tracheal stents, the material of choice.

4. Modified liquid silicone rubber

Through some special treatment, the properties of liquid silicone rubber change, so as to have more application scenarios and a wider range of applications. Commonly modified liquid silicone rubber includes antibacterial and conductive liquid silicone rubber has important applications and research value in biomedicine.

(1) Antimicrobial properties

LSR materials are used in medical devices because they are highly biocompatible and thermally stable.

(2) Conductivity

With the development of wearable electronic devices, the traditional semiconductor piezoresistive sensors have exposed the shortcomings of inflexibility, flexible sensors made of composite materials based on polymers and conductive fillers can solve the problem.

5. How to improve the performance of liquid silicone rubber?

Liquid silicone rubber LSR is prepared from Polydimethylsiloxane base rubber. PDMS materials are widely used in medical devices, cosmetic plastic surgery, and many other medical fields due to their excellent resistance to high temperatures, solvents, hydrophobicity, flame retardancy, oxidation, corrosion resistance, as well as low chemical reactivity and good biocompatibility in LSR molding process. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical field and support the provision of diversified customized solutions.