Silicone material not only can be used in industrial applications (silicone glue) but also are very closely linked to the textile industry. Over 20% of the world's silicone production is used in textile printing and dyeing auxiliaries. Silicone printing and dyeing additives have excellent heat resistance, cold resistance, water resistance, oxidation resistance, weather resistance, and electrical insulation properties. Why apply silicone for fabric??

Silicone in the textile printing and dyeing industry has a wide range of uses, it can be used as a fabric softener, non-fluorine waterproofing agent, wrinkle finishing agent, shrinkage finishing agent, etc., and widely used in a variety of fiber finishing, endowed with a wide range of excellent fabric properties. From the chemical fiber drawing, drawing, imitation down fiber production, to the textile pre-finishing carding, and strip, re-washing, dyeing in the deepening, brightening, defoaming, as well as fabric finishing coating, waterproofing, oil repellency, hydrophilic, anti-fouling, anti-static treatment and soft, springback finishing, almost every process can use silicone additives.

The following four aspects of the content of silicone additives and how they play a role in the textile industry:

- Why use silicones in the textile industry?

- What are the advantages of silicone additives for textiles?

- What kinds of silicone additives?

- How to make the performance of textiles better?

1. Why use silicones in the textile industry?

1.1 The Development of textile science and technology

The development of chemical fiber synthesis technology allows the textile industry can produce chemical fiber characteristics of textiles, which are very close to natural fibers in appearance and form and can be done to imitate silk-like, imitation hair-like wool, some "high-fidelity", high-quality synthetic fabrics can reach "to fake real The level of "fake to real". However, in terms of textile processing, simple physical processing can not make chemical fibers with natural fibers with the same chemical and irrational properties, the comfort of the fabric also can not be compared with natural fiber fabrics. Therefore, there need to use a variety of printing and dyeing additives for finishing, for pure natural fabrics, to create more added value, and for improving the defects and deficiencies of the fabrics, also need to be finished. For example, pure wool, cotton products, "super soft" finishing, stiffness, stain resistance, elasticity, washable, anti-static, flame retardant, blackout, ultraviolet protection, hygiene, and other finishing, to increase the functionality of the demand. In addition, the textile printing and dyeing process continues to put forward higher and higher requirements for additives.

![]()

1.2 The unique chemical structure of silicone

(1) Silicone oxygen bond structure Si-O-Si endowed with a larger bond angle and bond length, intermolecular forces are small, unlike the general organic polymer is easy to crystallize, so it has good permeability;

(2) Its higher bond energy in silicone polymers has outstanding heat resistance and excellent flexibility;

(3) Its molecular chain has a spiral structure and Methyl is to the outside, so that it is colorful, which has low surface tension, good water repellency, and defoaming function;

(4) Because the Silicone oxygen bond (Si-H) has a relatively large activity, it can be hydrolyzed and condensed under the action of high temperature and metal salts and then crosslinked into a film;

(5) Silicone quaternary ammonium salt with active groups has antibacterial and antimicrobial functions.

Due to their structural peculiarities, siloxane polymers have a series of characteristics such as lubrication, softness, water repellency, defoaming, antimicrobial, and anti-microbial, which are suitable for finishing various fibers such as cotton, linen, silk, wool, and so on. Therefore, silicone has been recognized as an excellent performance textile printing and dyeing auxiliary type.

![]()

1.3 Silicone Textile Additives Classification

Silicone textile printing and dyeing auxiliaries have experienced the development process from low-grade to high-grade. It is related to the activity of the silicone polymer and the reaction properties with the fiber. In silicone textile printing and dyeing additives varieties, there are no uniform naming and product standards. Silicone polymers with the chemical reaction of the division of reactive groups, are basically divided into three types: namely, inactive, reactive, and reactive groups with a polygroup of polysiloxane compounds.

2. What are the advantages of silicone additives for textiles?

Silicone additives are currently one of the most widely used textile additives, their main feature is the ability to make the fiber surface form a layer of good adhesion, water resistance, and high softness, and does not affect the air permeability of the film, which in turn improves the quality and performance of the fabric, and extend the service life of the fabric and smooth on it.

![]()

(1) Enhance the softness of cotton fabrics: Silicone additives can reduce the apparent tension on the surface of cotton fabrics, and reduce the fiber force, thus making the fabric softer and smooth on.

(2) Improve the breathability of cotton fabrics: Silicone additives can make the fabric fiber surface form a film, which reduces the friction between the fibers and improves the breathability of the fabric. These fabrics with low thickness can be used in medical applications.

(3) Improve the water resistance of cotton fabrics: Silicone additives can form silicone coated with water resistance on the surface of the fiber, thus improving the water resistance of cotton fabrics.

(4) Improve the wrinkle resistance of cotton fabrics: Silicone additives can reduce the coefficient of friction on the fiber surface, so that the friction between the fibers is reduced, thus improving the wrinkle resistance of cotton fabrics.

(5) Improve the washing resistance of cotton fabrics: Silicone additives can reduce the absorbency of cotton fabrics and surface friction, and reduce the wear and tear of the fibers so that the fabric is more washable and has good durability.

3. What kinds of silicone additives?

Known as polysiloxane, an organic polymer with a Si-O-Si structure, silicone has excellent heat resistance, cold resistance, water resistance, oxidation resistance, weather resistance, and electrical insulation properties. The following are several common uses of silicone printing and dyeing auxiliaries:

![]()

3.1 Silicone softener

Silicone fabric softener is widely used in the textile industry softener varieties. Compared with other softness, silicone fabric softeners and other types of softeners have low interface energy can be fully stretched and smooth on a variety of fiber surfaces, and have the advantage of a very good smooth soft touch.

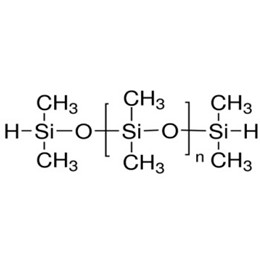

XJY-707 Hydride capped polydimethylsiloxane

It is soluble in organic solvents such as Aromatic/Petroleum Hydrocarbons, and insoluble in water. Because the molecular structure contains active hydrogen atoms, it can be synthesized by copolymerization polymer silicon hydrogen addition reaction and can be used in the manufacture of natural and synthetic fiber softeners. You need to wear rubber gloves when using.

3.2 Silicone waterproof agent

Silicone waterproof agents with smooth and soft, waterproof and breathable properties can be used as clothing fabrics, home textile fabrics waterproof finishing agents. When the silicone with active groups (such as Si-H, Si-OH, or Si-OR) in the presence of catalysts, it can be crosslinked into a film at lower temperatures, forming a silicone coating on the surface of the fabric and smooth on, while the silicone has a Hydrophobic Methyl, directional arrangement of the surface of the fiber gives the fiber a good waterproof effect, and does not affect the permeability of the fabric. But it needs to use rubber gloves.

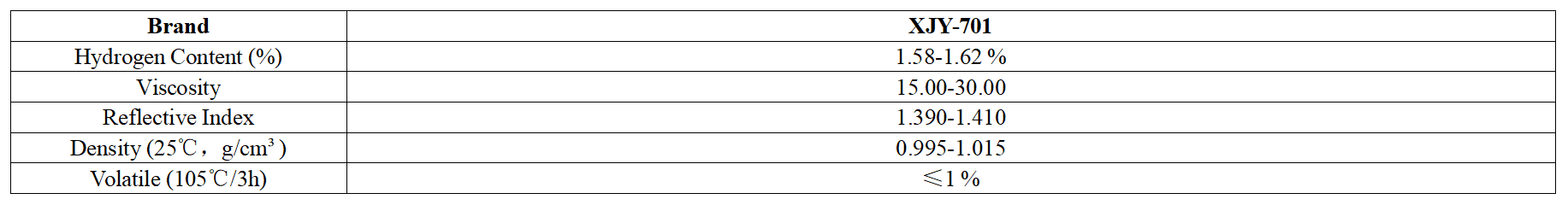

XJY-701 Polymethylhydrosiloxane can be used as a waterproofing agent for fabrics, glass, ceramics, paper, leather, metal, cement, marble, and other materials, especially for fabric waterproofing.

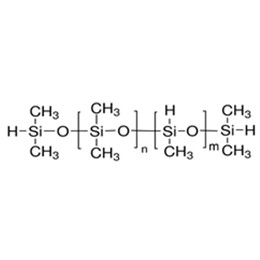

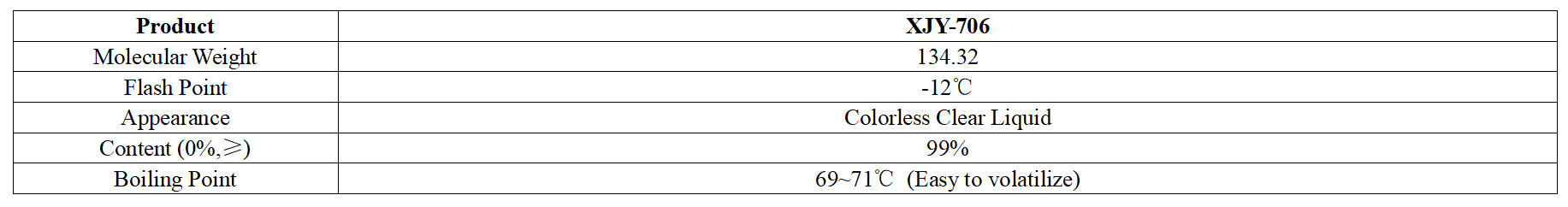

XJY-706 1,1,3,3-Tetramethyldisiloxane can be used as a waterproofing agent for textiles, and silicone coatings (such as smart textiles).

3.3 Anti-wrinkle finishing agent

Silicone wrinkle-free finishing agent can be achieved through two aspects of the wrinkle-free finishing effect:

(1) Silicone anti-wrinkle finishing agent with low molecular silicone can enter the fiber inside, it can use active groups of silicone molecules to crosslink with the active molecules of fiber;

(2) Silicone wrinkle finishing agent in the high molecular silicone can be formed on the surface of the fiber's high elasticity molecular film, which can make the fabric with a durable wrinkle finishing effect.

![]()

When the modified silicone as a finishing agent for cotton fabrics, as it has hydroxyl, amino, and other active groups that can be cross-linked with the polar groups on the fiber, silicone printing and dyeing auxiliaries and fibers firmly combined, and can effectively penetrate into the fiber inside, inside and outside of the film, and very well improve the folding of cotton fabrics back performance.

XJY-711 Hydride-Terminated Methylhydrosiloxane/Dimethylsiloxane Copolymer can be used as a fabric finishing agent, such as in athletic wear.

3.4 Shrinkage prevention finishing agent

The reason for fabric shrinkage wrinkles is that external forces to make the fiber bend deformation, and relaxation are not fully restored to their original state caused by.

As wool has a special form of structure and better elasticity, wool fabrics will occur after a large contraction in the first wash and many times. Several modified silicone finishing agents for compounding, and then on the wool fabric finishing, can give the fabric good shrinkage performance. Mainly because a small amount of the silicone finishing agent silicone into the fiber inside, can be crosslinked into a polymer elastic film, this film can wrap the wool fiber surface scales, so that the directional coefficient of friction is reduced to give wool fabrics good anti-wrinkle properties.

![]()

4. How to make the performance of textiles better?

Silicone printing and dyeing additives with special structures and excellent performance (such as flame resistance) can be used as fabric softeners, non-fluorine waterproofing agents, anti-wrinkle finishing agents, shrink-proof finishing agents, hydrophilic finishing agents, dark-colored processing agents, anti-melt finishing agents, other printing and dyeing additives to give the textile a variety of excellent performance, which is widely used in cotton, linen, silk, wool and other kinds of fibers finishing. How to improve the competitiveness of your silicone products on working time?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone oil products can meet the needs of the textile field and support the provision of diversified customized solutions.