When encapsulating sensitive electronic components with silicone potting material and encapsulating compounds adhesive in electronic applications and casting applications, there are two kinds: condensation type and addition molding type. What is the difference between the two?

| Generally speaking, the adhesion of condensation potting compounds will be better, up to IP68, so it is mostly used for electronic components with high waterproof performance requirements; The addition molding potting adhesives have better thermal conductivity and provide electrical insulation, high strength, no corrosion, small shrinkage and environmental protection. |

However, the addition of molding potting compounds has always been a difficult problem in terms of waterproof performance. At the same time, it is easy to be poisoned and not cured. It is very easy to react with nitrogen, sulfur, phosphorus, arsenic, organotin curing agent, stabilizer, epoxy resin curing agent and other compounds. At present, it can only be solved by spraying primer and three proofing paint.

- Solidification

- Silicone Potting Compound Applications

- How do silicone potting materials take effect in potting compounds?

- XJY Silicones—First choice silicone raw material supplier of potting compounds

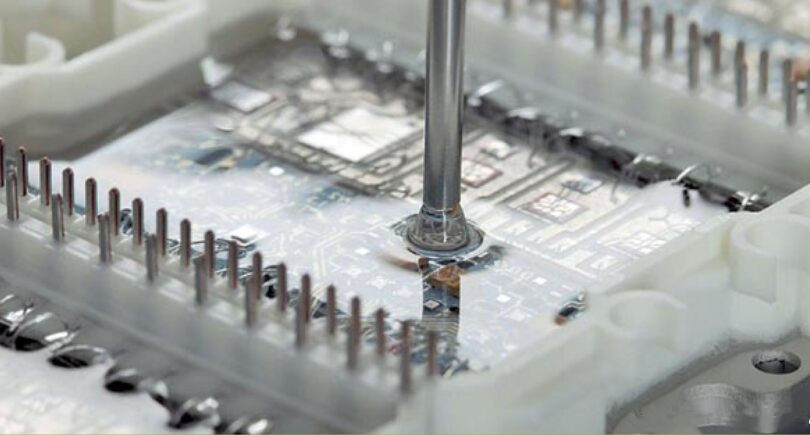

Solidification

Condensation type silicone potting adhesive is a kind of adhesive combination curing that uses silica gel and a curing agent to condense and remove small molecules in the presence of water in the air. It will shrink and by-products will be released during the curing process.

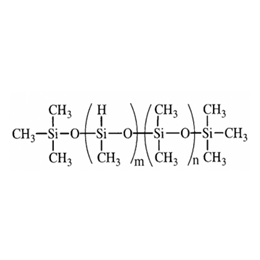

The addition molding silicone potting adhesive is bonded by the addition reaction of silicon hydrogen bond and ethylene double bond. After AB is mixed, it will complete the curing by itself. Even in a closed container, it does not need to be opened to the atmosphere. There are no small molecules in the reaction process, which determines the difference in their performance.

The addition molding silicone potting adhesive can be deeply and rapidly vulcanized, which is particularly obvious in the transparent color. The condensed transparent with a thickness of more than 3mm will be difficult to cure, while the addition molding transparent will not be affected by the thickness.

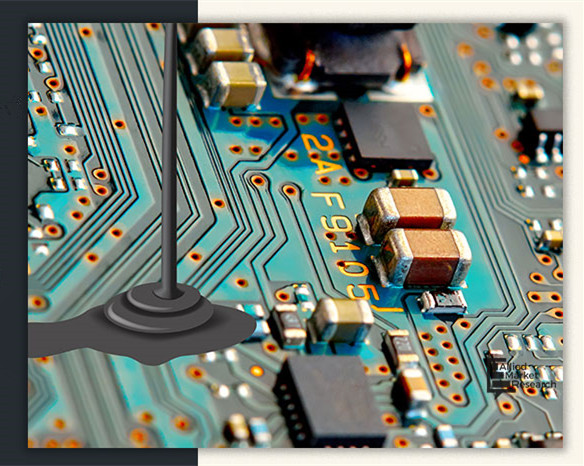

Silicone Potting Compound Applications

Addition Molding Potting Compounds

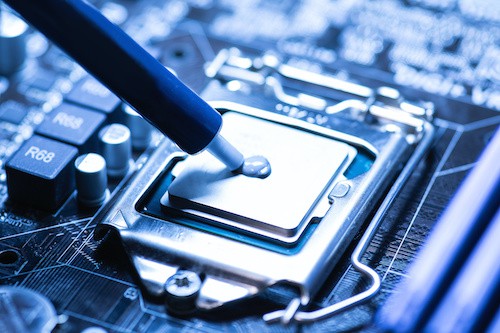

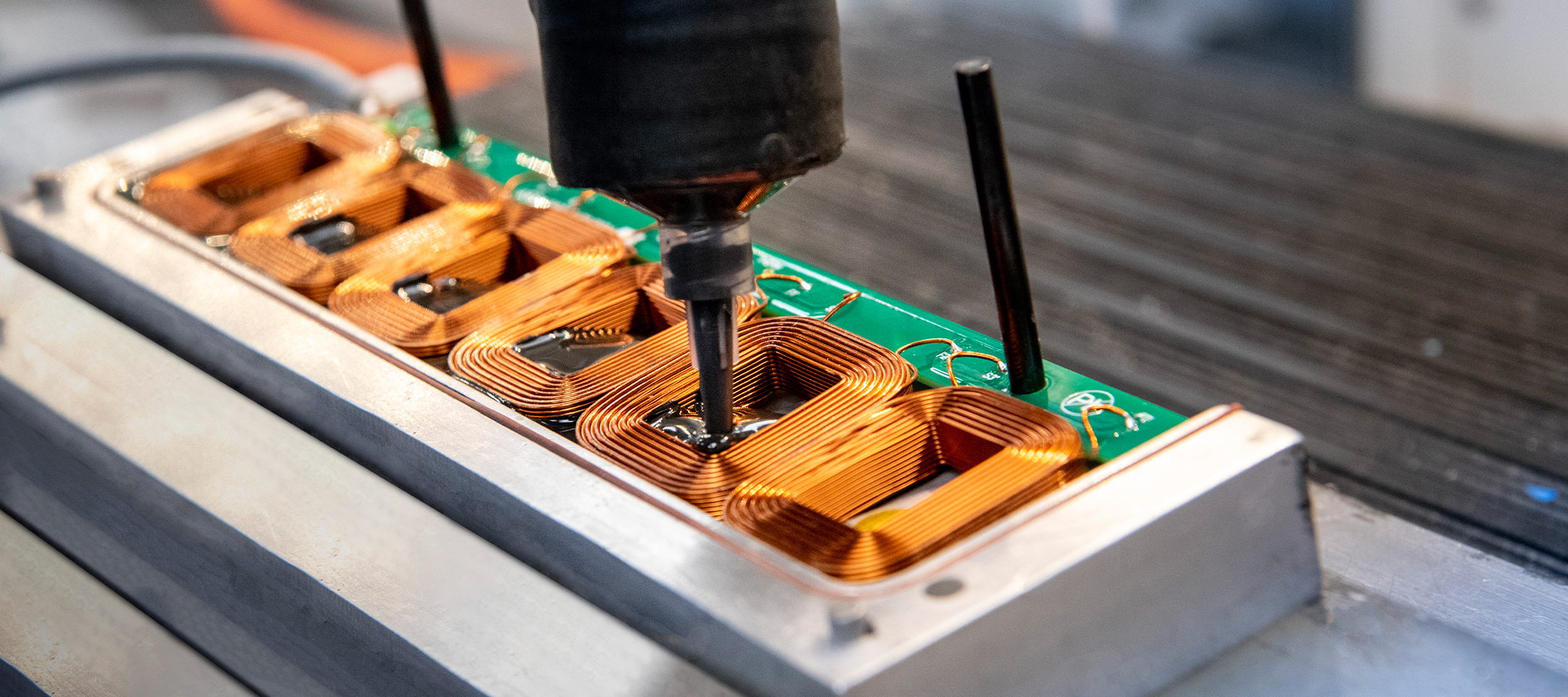

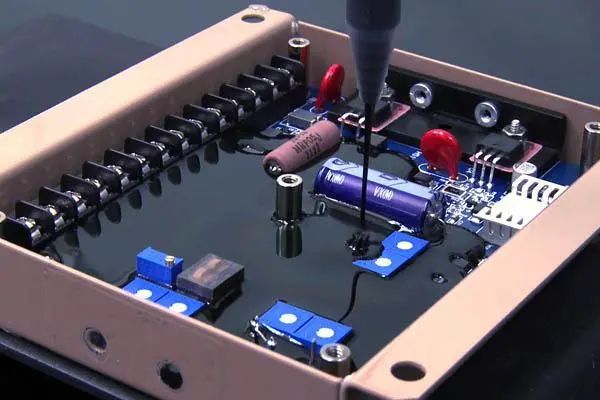

The performance parameters of addition silicone potting adhesive, such as hardness, tensile strength, shear strength, volume resistivity and viscosity, can be adjusted or customized according to different uses and occasions. The main applications are as follows: it is applicable to the coating, pouring and potting of general waterproof, moisture-proof and gas pollution-proof products; Sealing and protection of various electronic circuits, sealing and protection of small machinery, potting and protection of module power supply and circuit board. For example, HID lamp power supply potting, LED module potting, led waterproof power supply potting, electronic module power supply potting, lightning protection module electronic potting, negative ion generator potting, ballast electronic potting, automobile ignition system module power supply potting, etc. Potting of PTC heating element and sensor; Thyristor, semiconductor electronics.

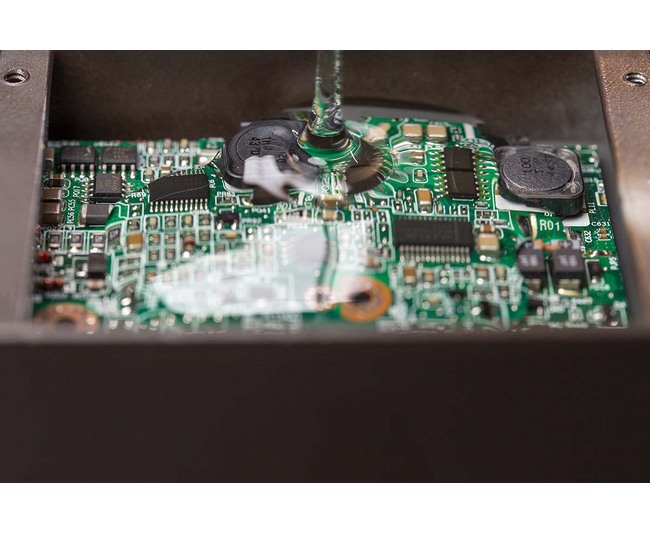

Condensation Potting compounds

Condensation silicone potting compound is a kind of silicone rubber that is cured by moisture in the air and mixed catalyst. The curing time mainly depends on the amount of catalyst. The more the amount of catalyst, the faster the curing speed. However, shrinkage and by-products are released during curing. The one-part condensation silicone RTV is not suitable for applications thicker than 10mm as it will cure to form a waterproof membrane and prevent curing of the silicone on the bottom of the case. One-part RTV silicones are cured into elastomers using a variety of cross-linking agents that produce by-products, some of which can be hazardous to complete electronic assembly-sensitive components. Therefore, it's recommended to use dealcoholized and ketone single-component silica gels as encapsulation materials. Condensation silicone potting compound can be used for bonding, sealing, good moisture resistance and encapsulation protection of electronic components. After curing, it can play the roles of waterproof, moisture-proof, dust-proof, insulation, heat conduction, sealing, anti-corrosion, temperature resistance, and external shock and vibration resistance. It can improve the performance of electronic and electrical sensitive components, strengthen the integrity of electronic assemblies, and improve the insulation between internal components and lines.

How do silicone potting materials take effect in potting compounds?

The role of vinyl silicone oil in potting compounds

Vinyl silicone oil is the main body of the two-component potting compound, and the technical parameters of vinyl silicone oil directly affect the performance and use process of the potting compound.

The main technical parameters of vinyl silicone oil are viscosity and vinyl content.

Usually, for the application of potting glue, the glue is required to have a lower viscosity, and vinyl silicone oil is the component with the highest content in the raw material of silicone potting glue. The viscosity of vinyl silicone oil can most affect the viscosity of the potting glue. , and also most affect the fit of the potting. If the viscosity of the silicone oil is too high, the potting compound may not be able to closely adhere to the components and thus not be able to isolate oxygen and moisture.

Therefore, in the selection of the viscosity of the silicone oil, the viscosity should not be too high on the basis that the silicone oil can closely fit the components.

However, the viscosity of vinyl silicone oil is directly related to the final crosslinking density. Low viscosity means that the molecular weight of vinyl silicone oil is smaller. Usually in silicone rubber, when the viscosity of the main silicone oil is higher, the corresponding mechanical properties will be stronger.

The role of silicone resin in potting compounds

Silicone resins tend to be more expensive than epoxies or urethanes, but find use where high and or low continuous operating temperature resistance (-50 to 200°C) are involved. Their inherent high flexibility makes these resins particularly suitable for applications where there is a high level of thermal shock involved or a high frequency of thermal cycling. The amount of heat given off during the curing of silicone resins is very low indeed, making them particularly suitable for use in potting electronic assembly temperature-sensitive delicate components. Silicones have excellent adhesion to a wide range of substrates, including most common metals and plastics. In general silicones are soft, which means they are not as resilient as epoxy potting or polyurethane resins.

Silicone resins are based on silicone polymers of various molecular weights, with different terminal groups to provide the required functionality. As with polyurethanes the hardness of the resin can be adjusted by using branched polymers to increase the cross-link density of the cured resin. Silicones use a number of different catalysts to initiate the curing process, in many cases, these are based on platinum complexes, which can easily be poisoned by trace amounts of other potting materials, amines are particularly effective at reducing the activity of these catalysts. It is not recommended to cure epoxies and silicones in the same oven. Also depending upon the type of terminal groups (vinyl or hydroxyl) will determine the curing reaction, and if moisture is required. Unlike epoxies, polyesters and polyurethanes, silicones generally cure the exposed surface down through the body of the resin. This means that the silicone will have a rapid skin time (sometimes called the tack time), but then the curing reaction is progressive through the body of the resin, this means that the depth of the resin will determine the cure time.

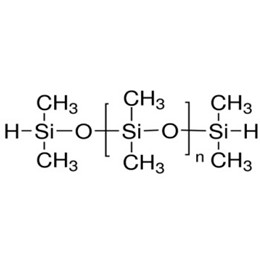

The role of Hydrogen silicone fluid in potting compounds

The stress of the silicone potting compound comes from the addition reaction of the hydrogen of the hydrogen-containing silicone oil and the double bond of the vinyl silicone oil to form a saturated structure. The less the content of the hydrogen-containing silicone oil, the smaller the stress of the silicone potting compound; secondly, since the structural surface of silica has many -oh hydrophilic structures, the filler treatment agent can react with the -oh hydrophilic structure on the silica surface to form a lipophilic structure, which is conducive to the mixing of fillers and silicone oil; finally, as a tackifier, compared with ordinary tackifiers, the silane coupling agent with the epoxy group and the vinyl group has more vinyl groups, so it can polymerize with the silica gel system itself, thereby improving the viscosity of the silicone encapsulant.

What is the relationship between hydrogen-containing silicone oil and potting material compounds?

The mechanical properties of the potting compound are very sensitive to the addition of hydrogen-containing silicone oil. With the increase of the amount of hydrogen-containing silicone oil, the hardness of the potting compound gradually increases, the tensile strength first increases and then decreases, and the elongation at break decreases continuously.

How to choose hydrogen-containing silicone oil for potting compounds?

There are two kinds of hydrogen-containing silicone oil that need to be used for potting glue.

| XJY-702 Methylhydrosiloxane dimethylsiloxane Copolymer Side hydrogen silicone oil is the most commonly used cross-linking agent for the addition of silica gel. Generally speaking, the use of a centralized cross-linking mode is beneficial to the improvement of the mechanical properties of the potting compound. Silicone oil containing side silicon-hydrogen bonds is used as a cross-linking agent for vinyl glue, which will make the silicone potting glue better. According to the level of hydrogen content, the performance will change to a certain extent. Generally, the side hydrogen content of 0.5-1.2% is the most commonly used, and its performance is also relatively good. |

| XJY-707 Hydride Terminated Polydimethylsiloxane The terminal hydrogen-containing silicone oil is mainly used as a chain extender in the addition type silica gel system, which can improve the flexibility of the silica gel and has a significant effect on the elongation and tensile strength. The more commonly used end-position hydrogen-containing silicone oil (without lateral hydrogen), the hydrogen content is about 0.05-0.1%, the viscosity is low, and the amount of addition is not much. Hydrogen-terminated silicone oil has a better effect on the thermal properties of the potting compound. |