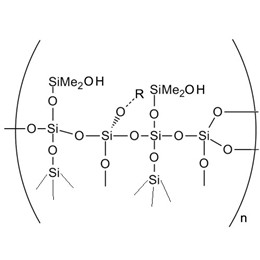

Characteristics of silicone

Silicone is a kind of synthetic high molecular polymer with silicon atoms and oxygen atoms as the main chain. Since the silicon-oxygen structure constituting the main chain has a strong chemical bond, the molecules of silicone polymers are much more stable to heat and oxygen than general organic polymers. Although the mechanical properties of silicone at room temperature are not much different from other materials, it has excellent physical and mechanical properties at high and low temperatures. The temperature is repeatedly changed from -60 to +250 ℃ without affecting its performance. Therefore, the silicone polymer can be used for a long time in this temperature range. Some silicone polymers can be used normally at temperatures as low as -100°C. In addition, due to the dipole effect in the silicone molecule, it can effectively buffer and weaken the influence of the external electric field, thereby protecting the hydroxyl group connected to the silicon atom and making it less susceptible to physical factors or chemical agents. In addition to basic corrosion resistance, radiation resistance, high and low-temperature resistance, the products made of polyorganosiloxane also have low moisture absorption, high insulation resistance, low dielectric constant, low stress, vibration reduction, environmental protection, Low toxicity, non-flammability, and reworkability. Therefore, silicone is made into a variety of adhesive sealants, potting compounds, insulating coatings, and silicone greases and other finished products to be used in various electronic devices.

Application of silicone materials in automotive electronics

Silicone for electronics devices includes adhesives and sealants, potting compounds, gels, insulating coatings, thermally conductive adhesives, and other materials. These materials are used to protect engine control modules, ignition coils and ignition modules, power system modules, braking system modules, exhaust emission control modules, power systems, lighting systems, various sensors, connectors, etc.

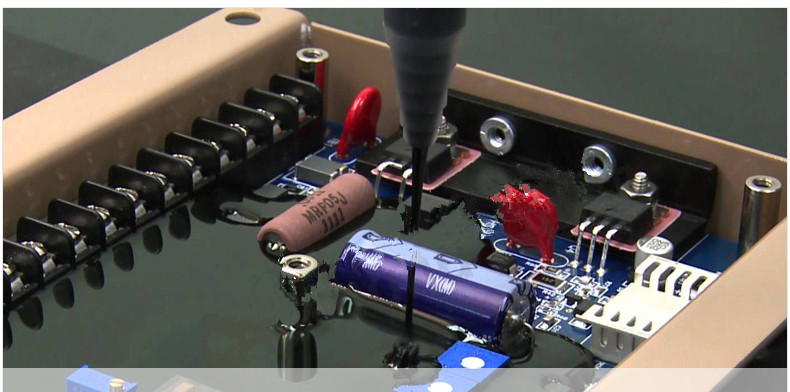

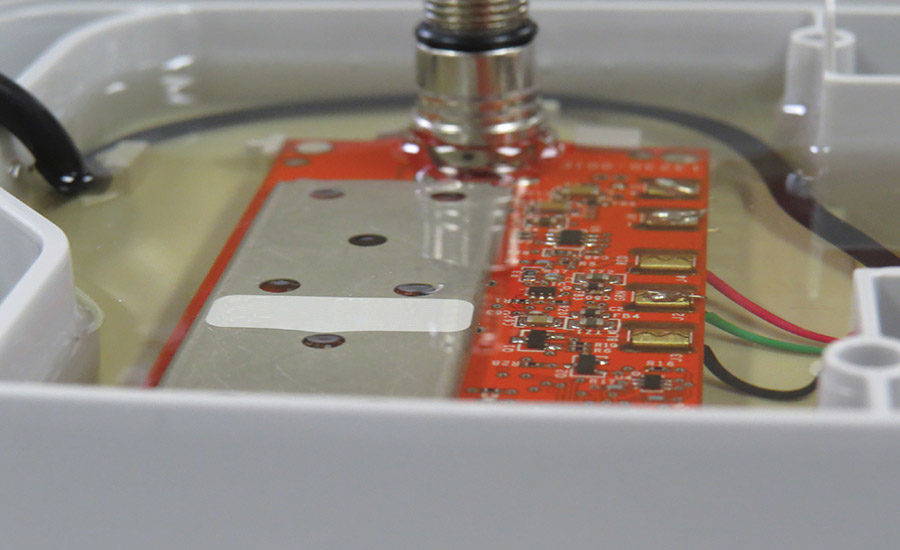

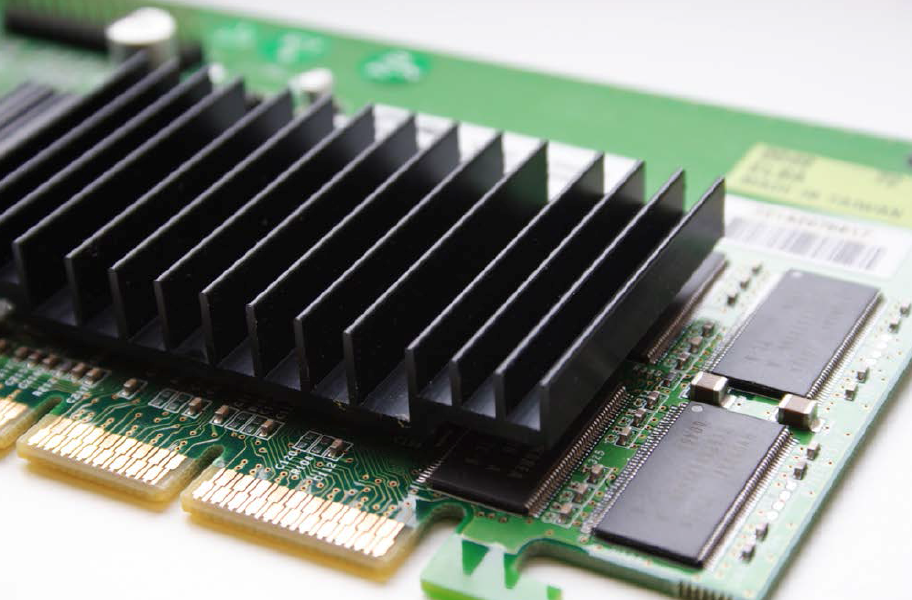

Adhesive and automotive silicone sealant: Used in various control modules as the bonding and fixing of components on the circuit board, or for auxiliary fixing of large components, such as capacitors, inductors, and coils to prevent components from being damaged. Vibration and fall off, it has the function of fixing and damping. In addition, silicone for electronics is also used for module housing bonding and sealing, which has the functions of sealing, moisture-proof, anti-fouling, and anti-corrosion. If a thermally conductive adhesive is used, it has both bonding and heat dissipation functions. It can be used to fix power devices or bond heat sinks to achieve bonding and heat dissipation functions. The bonding between the circuit board and the aluminum heat sink in the engine control module is a typical application of thermally conductive adhesives.

![]()

Potting glue: used on all kinds of control modules to do integral and general potting of components to meet the basic requirements of moisture-proof, anti-fouling, and anti-corrosion. The use of silicone potting material can reduce stress and withstand high and low-temperature impacts. For high-power control modules, thermal conductivity potting glue is used to achieve the function of heat dissipation. Silicone potting materials are widely used in wiper controllers and power system modules. The potting of HID (High-Intensity Discharge) lamp module is a typical application. The HID module contains an igniter and a converter. The potting glue used must have good bonding properties and excellent dielectric properties, can prevent dust and water seepage, and play a sufficient insulation protection effect; the potting glue must be relatively soft to prevent the solder joints from falling off; The module contains some heating elements, so the potting glue needs to have a certain heat conduction effect; in order to prevent volatile substances from atomizing on the lamp tube and the refractor, the potting glue is preferably refined; the final potting glue must be UL94V-0 flame retardant level.

Gel: Silicone gel material is the most important glue used in silicone for electronics of automotive devices. The function is similar to silicone potting glue, but it provides further stress reduction and vibration reduction functions. Silicone for electronics is especially functional for the protection of fine lines under vibration and extremely low-temperature conditions. The extremely low stress of silicone gel potting materials and the original insulation and moisture-proof properties of silicone make silicone gel potting materials the main potting protection materials in automotive electronics. Protecting engine control modules, ignition coils, etc. are typical applications. The power module of the most advanced steam-electricity shared engine uses low-temperature silicone gel for electronics as its potting protection material. This kind of potting material needs to have excellent dust and water seepage resistance and requires high flexibility, can protect the connection from stress, and maintain high flexibility even in an environment of -55°C.

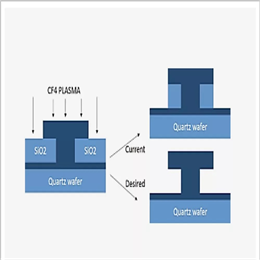

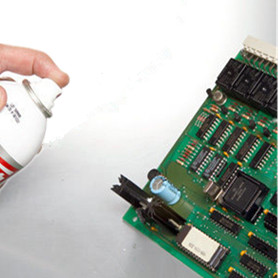

Electrical insulation coating: applied on circuit boards or semiconductor components in various control systems or modules to achieve the purpose of preventing moisture, pollution, and corrosion. Electrical insulation coating can also be coated on the electrode with higher voltage or current to prevent flashover and short circuits. By coating, an insulating and moisture-proof layer can be formed on the surface of the circuit board and the components, and it can also avoid short circuits caused by contaminants, reduce the contact between the components and the environment, and delay corrosion. And to protect the metal contacts in the electronic device from environmental damage, so that the product's environmental resistance reliability has a qualitative leap. The protection of circuit boards and sensors in various modules is one of the typical applications of electrical insulation coating. For example, the circuit boards in wipers can be protected with solvent-free conformal coatings to protect against water and other liquids.

Thermal Conductive Material: Many high-power components in various electronic control modules will generate a lot of heat when in use, which will make the temperature of the module gradually increase during operation. In order to avoid damage to components and circuits due to excessive temperature, there must be a proper heat dissipation path to maintain the control module at a proper temperature. No matter what kind of heat dissipation method is adopted, a thermally conductive material must be used as a medium to reduce the interface contact thermal resistance and increase the heat dissipation efficiency. Silicone thermally conductive materials include thermally conductive adhesives, potting glues, and gel potting materials. The thermally conductive adhesives are used to bond and fix power components and heat sinks. Thermally conductive potting glue and gel are used as module potting, and materials of this technology, such as thermally conductive adhesives, are used in engine control modules and power system modules.

Application development of silicone materials

Silicone for electronics materials has been used in various automotive devices for decades. With the development and close integration of the automobile industry and the electronics industry, various electronic control mechanisms and modules have been widely used in various control systems to improve the performance of automobiles and the comfort of passengers. All kinds of sophisticated electronic control modules need appropriate protective materials to protect to ensure their stability and reliability. The high-performance silicone for electronics material ensures the stability and reliability of various electronic control modules with its unique insulation, moisture-proof, anti-fouling, anti-corrosion properties, and special low-stress, heat-resistant, and cold-resistant properties, and also provides automotive There is room for the further development of electronic devices and the further development of automobile industry technology.

XJY Silicones

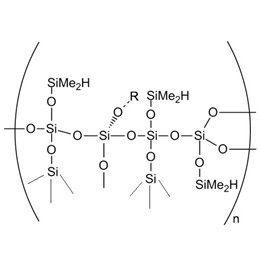

XJY Silicones can provide XJY-8206 VMQ/VQM silicone resin series that can be applied in the electrical sealant.

| Brand | XJY-8206N-3 | XJY-8206N-5 | XJY-8206N-6 | XJY-8206N-7 | XJY-8206N-8 | XJY-8206N-9 | XJY-8206N-10 |

| Product Name | Methyl VMQ Silicone Resin + Vinyl Silicone Oil Polydimethylsiloxane | ||||||

| Appearance | Colorless Transparent Liquid | ||||||

| Viscosity (25℃, mm2/s) | 10000 -15000 | 9000 -13000 | 42000 -65000 | 10000 -20000 | 12000 -20000 | 10000 -20000 | 85000 -115000 |

| Vinyl Content | >1.23-1.3% | >1.65-1.8% | >1.40% | >0.7-0.9% | >1.2-1.3% | >0.3-0.6% | >1.2-1.3% |

XJY Silicones as one of the leading silicone manufacturers is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry. Our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.