The global healthcare industry is constantly accelerating the development of new technologies and the search for more advanced service models to help people prevent and cure diseases. Innovative silicone (food-grade silicone) medical applications solutions are part of this trend, enabling healthcare professionals to explore new ways to treat complex diseases, accelerate patient recovery, and reduce healthcare costs while delivering high-quality treatments. What are the applications of medical silicone?

There are six aspects to introducing silicone in the medical field:

- Silicone in surgery

- Silicone in wound Care

- Silicone in drugs and medication delivery

- Silicone in dental

- Silicone in diagnostics and monitoring

- How can medical silicone rubber perform better?

1. Silicone in surgery

Medical-grade silicone materials have been widely used in medical appliances and equipment needed for surgical procedures because of their excellent biocompatibility, chemical inertness, hypoallergenic, physical properties, and stability in a variety of environments, which in line with the most stringent medical and regulatory requirements.

1.1 For Cardiac resynchronization devices

Devices (such as pacemakers) are critical and sophisticated medical devices that regulate life-threatening cardiac problems such as tachycardia. Long-term implantable medical silicone series are specially designed and manufactured to meet the high material performance requirements of cardiac resynchronization devices and to protect sensitive devices from corrosive substances.

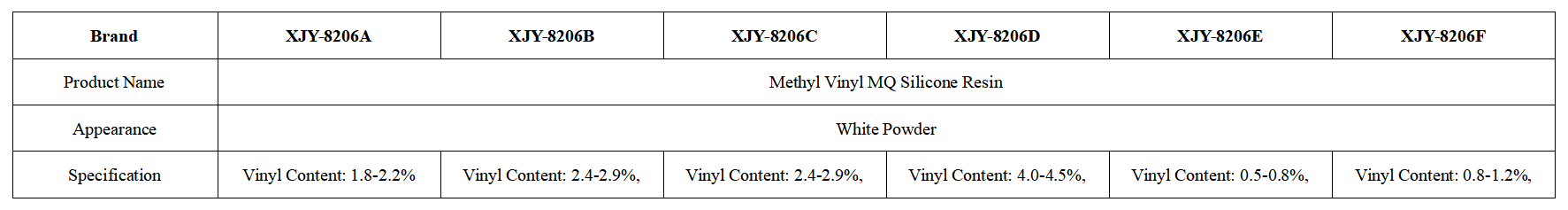

XJY-8206 Methyl vinyl MQ Silicone Resin

It is a solid powder resin, that can be used as reinforcing filler for additive molding silicone rubber, and also can be used as the basic silicone filler raw material for dental use with high transparency and high hardness.

1.2 For medical stents

The core role of the stent is to keep the blood vessels, airways, ureters, and other pathways in the human body. Silicone biograde and drug delivery grade rubber solutions are applied to the overall stent (e.g. airway stent) and the stent surface coating, which can improve the stent's corrosion resistance, strain resistance, and play a role in preventing coagulation, and reducing the inward growth of tissues.

1.3 For medical catheter

Materials used in the manufacture of medical catheters need to be well-biocompatible, hypoallergenic, and sterilizable to enhance patient tolerance. Because medical catheters are typically single-use, these materials should also support the need for high-performance manufacturing. Silicone solutions with low shrinkage, high elasticity, easy processing, and high mechanical properties are suitable for the relevant criteria for biocompatibility.

1.4 For implantable neurostimulation devices

Neurostimulation devices are usually surgically implanted into the patient's body and function via thin wires or leads. Implantable silicone materials can be used for gaskets, seals, adhesives, wire insulation, and drug delivery systems in the device.

1.5 For medical fluid delivery systems

Fluid management in medical devices - such as tubing, catheters, and valves - plays a vital role in the healthcare industry and patient care. Silicone offers a standard and self-lubricating series of technology solutions, which not only offer the advantages of high elasticity, low compression set, excellent physical properties, and mold release properties but also meet the customized needs of our customers.

2. Silicone in wound Care

Manufacturers of wound care products use silicones to produce skin-friendly, low-trauma bandages, dressings, and surgical tapes. Silicone materials have excellent biocompatibility, making wound care products more comfortable to use and less irritating to the skin.

2.1 For highly functional wound care

In the manufacture of absorbent foam wound dressings, topical ulcer dressings, postoperative dressings, and wound contact layers (NPWT) for negative pressure wound therapy, they can help dressings achieve non-invasive and painless wound contact and removal, meet the most stringent requirements needed for high-functioning wound care, and provide an ideal care environment for wound healing.

2.2 For medical tape and film

Silicone materials can help surgical films (and incision membranes) in the skin to better fixation, thereby reducing the risk of infection in the patient during the surgical incision process. Its efficient bonding performance and repeatable adhesive properties make this product ideal for the manufacture of medical tapes and films.

Silicone technology solutions are used to reduce pain and irritation to wounds. Adhesive bandages using silicone flexible skin adhesives can be firmly attached and easily removed, reducing skin irritation. At the same time, this series of products can make the adhesive bandage repeat application, which helps doctors observe the recovery of the patient's wound during treatment.

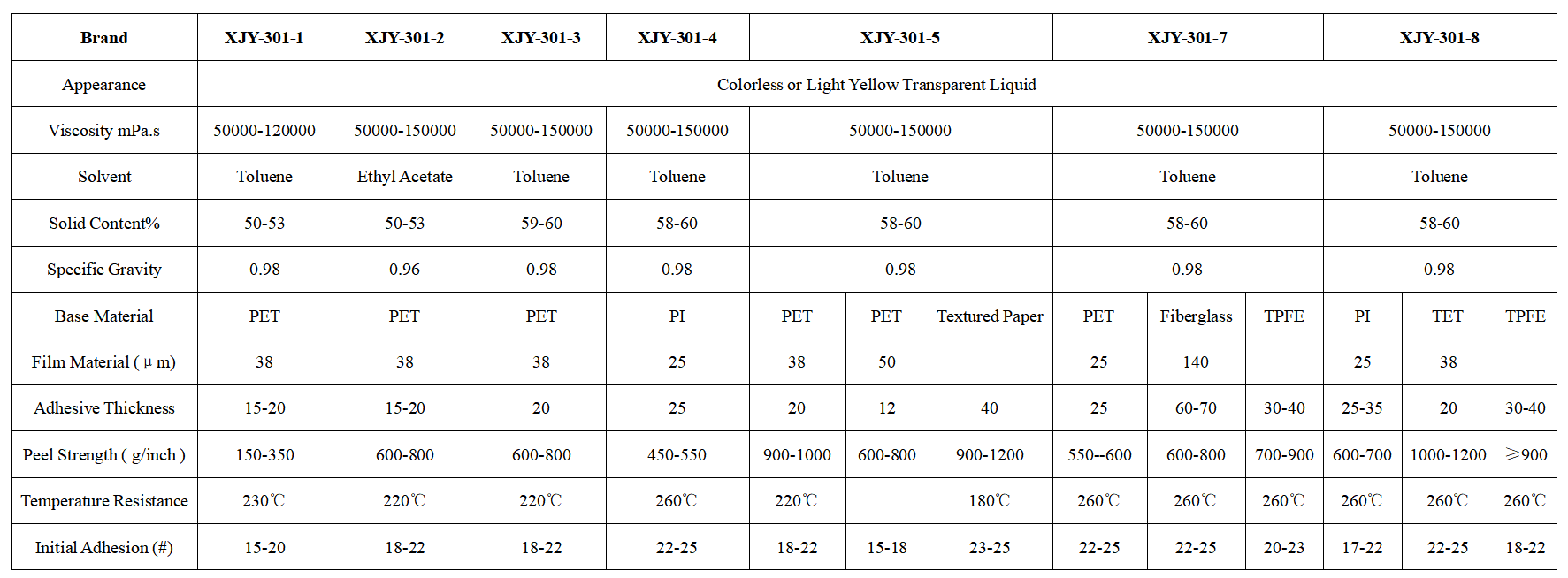

XJY-301 Silicone Pressure-sensitive Adhesive (PSA)

It is a specific structure of silicone resin and high molecular weight polydimethylsiloxane complex, it is an adhesive applied to specific scenarios under the conditions of the adhesive, has a high-temperature resistance, high stability, good electrical insulation, good transparency, high strength elastic bonds on human body, and other characteristics, have a wide range of applications in the medical and other fields.

2.3 Orthotics and prosthetics

Medical-grade silicones for orthotics and prosthetics can enhance the mechanical properties and comfort of the products, with the advantages of lightweight, good tactility, and fine appearance. The soft and elastic silicone materials used in prosthetic liners can protect the surface of the patient's residual limb, avoid skin abrasion, and reduce the pain of amputation patients. Compared with other carbon-based materials, silicone materials are more durable and less irritating to the skin.

A full range of medical-grade silicone elastomers have excellent biocompatibility, reducing irritation and sensitization of delicate skin. They enable foot care products and orthotics to have better resilience, providing adequate impact protection and weight absorption.

2.4 For breast prostheses and pads

Medical grade silicone gel has lightweight, better softness and damping properties, bringing the best elasticity and resilience to breast fillers and pads, providing patients with a more comfortable wearing experience. In addition, the unique viscoelastic properties make it the material of choice for the manufacture of care products such as pads, which can better protect patient safety and facilitate the operation of operating room staff.

Silicone series products with a variety of hardness options, biocompatibility in line with ISO 10993 standards, and they have better mechanical properties and durability, which can help prosthetic pads more closely with the body to provide patients with a better experience.

3. Silicone in drugs and medication delivery

When they are needed to deliver critical medicinal fluids or as materials for pharmaceutical excipients, medical-grade silicone materials are ideal for drug manufacturing and drug delivery applications of medical device manufacturers because of their biocompatibility, chemical inertness, thermal stability, soft physical properties, and environmental stability.

3.1 For biopharmaceuticals

Biomedical-grade silicone technology solutions are highly elastic, easy to process, have high physical properties, are biocompatible in accordance with relevant standards, and are able to meet stringent quality and manufacturing standards, which are mainly used in critical fluid handling applications in the pharmaceutical field.

3.2 For drug elution devices

Medical-grade silicone series products have been tested to meet the requirements of stringent medical standards. In addition to a full range of liquid silicone rubber (LSR) and high-consistency rubber (HCR) for long-term implantable devices, silicone also offers a range of products for medical device manufacturing.

4. Silicone in dental

Medical-grade silicone rubber materials need to have a high degree of reproduction, reliable reproduction properties, and the ability to produce an impression in a very short curing time. Silicones has more than 20 years of experience in the dental industry and is able to offer innovative medical-grade materials products and tailored silicone solutions produced in a state-of-the-art environment.

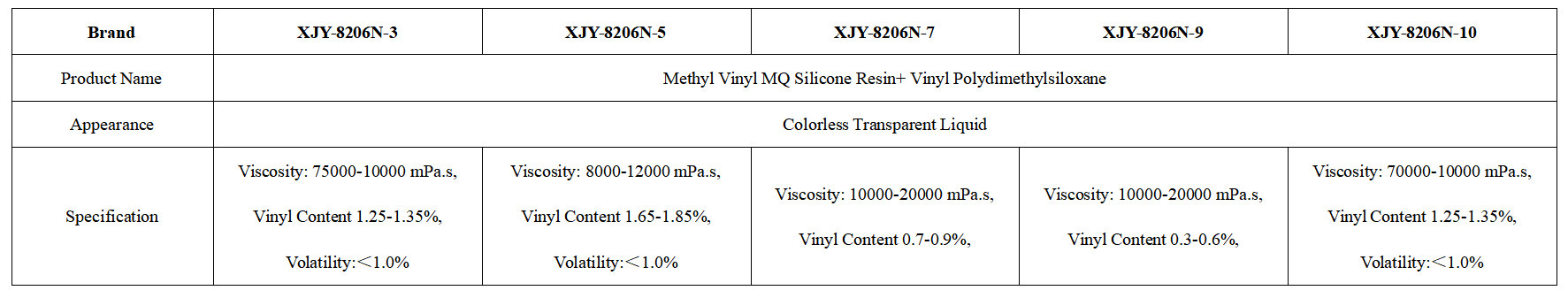

XJY-8206N Methyl Vinyl MQ Silicone Resin + Vinyl Polydimethylsiloxane

It is a colorless and transparent liquid resin composed of vinyl MQ organic silicone resin and vinyl silicone oil. It can be used in LSR liquid silicone rubber and other additives and also has good reinforcing and hardening properties, widely used in the medical field.

4.1 For dental impressions

Silicones utilizes proprietary technology to develop and manufacture high-quality dental materials that enable high-fidelity, reliable, and fast impressions and reproductions. Customers are provided with impression materials that are very hydrophilic, highly thixotropic, and highly fluid under shear, allowing for better handling by the doctor during use.

4.2 Reproduction for dental laboratories

The silicone rubber technology solutions provide the advantages of low viscosity, easy molding, high elasticity, and high tear strength, capable of reproducing precise details, and at the same time, they have good compatibility with gypsum, polyurethane resins, propionic acid resins, and a variety of hardnesses, which can fully satisfy the customer's production needs, and can also provide customized services in the medical industry.

5. Silicone in diagnostics and monitoring

Manufacturers of diagnostic or sensing devices use medical-grade silicones to make disposable gear and home health devices, microfluidic chips, gaskets, and liners, not only because of silicones' inertness and ease of processing for multiple components, but also because of their excellent biocompatibility.

5.1 For in vitro diagnostic devices

In vitro diagnostic (IVD) prompt oncology testing (POCT) is an emerging trend in diagnostics because it enables patients to receive a one-time health diagnosis at home. Silicone technology solutions facilitate micron-scale manufacturing and the integration of valves, micro-pumps, and other components.

5.2 For 3D printed parts and medical training aids

Combining the unique versatility of silicone with the flexibility of additive manufacturing/3D printing, utilizing silicone rubber to realize the potential of additive manufacturing/3D printing opens up a wide range of opportunities that would not be possible using traditional processing techniques.

6. How can medical silicone rubber perform better?

Silicone not only meets the basic requirements of medical polymer materials but also has the characteristics of high-temperature resistance, low-temperature resistance, non-toxic, biological aging resistance, small reaction to human tissue, and good physical and mechanical properties. Therefore, it has become a typical medical polymer material and is widely used in healthcare and biomedical engineering fields. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the medical field and support the provision of diversified customized solutions.