Silicone materials are both organic materials and inorganic materials, showing many unique physical and chemical properties, such as non-toxic and odorless, weather resistance, electrical insulation, oxidation resistance, low surface energy, biological inertia, flame retardant, hydrophobicity, etc. It has been widely used in the defense industry, energy development, light industry and food, textile, electronics and electricity, machinery, construction, transportation, medical and pharmaceutical, daily life, and other fields.

Structure and classification of MQ resin

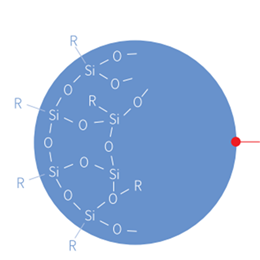

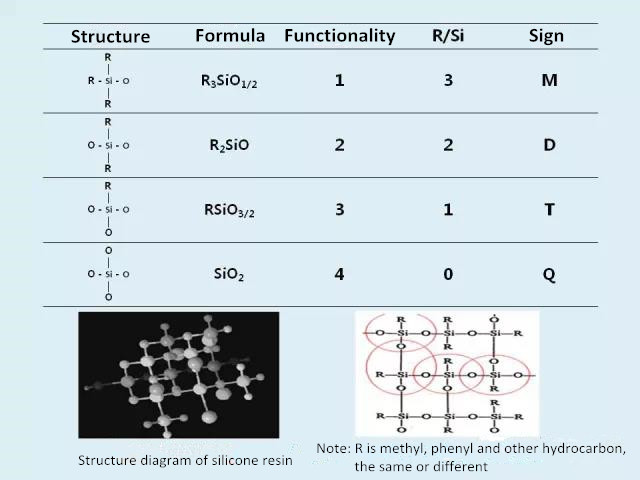

Silicone MQ resin is a kind of silicone resin with a unique structure. It is a three-dimensional spherical silicone resin generated by the co-hydrolysis and polycondensation reaction of silicone compounds containing four-functional siloxane chains (SiO4/2, Q) and silicone compounds containing a single-functional siloxane chain (R3SiO1/2, M). Its molar mass is generally 1000 ~ 8000g/mol, with a viscous fluid to solid powder state, hard and brittle, glass transition temperature (Tg) range is very wide.

It is generally believed that silicone MQ resin is a two-layer compact spherical body, in which the core is SiO chain connection, high density, the degree of polymerization of 15 ~ 50 cage SiO2, the spherical shell is low-density R3SiO1/2 layer.

Silicone MQ resin has a variety of different types due to the different organic group R on the shell:

When R is all methyl, it is called methyl MQ silicone or MQ silicone for short; When part R is H, it is called methyl hydrogen-containing MQ silicone; There are methyl phenyl MQ resin, vinyl MQ silicone tree, phenyl MQ resin, fluorine silicone MQ resin, MDQ, MTQ silicone resin and so on. The properties and application range of silicone MQ resin mainly depend on its synthesis process conditions and the type and number of organic groups in the molecule, that is, the M link and Q link ratio. Among them, the organic group R mainly increases compatibility with other components and plays a viscosifying role, while the SiO4/2 chain mainly improves the strength of the composite material and plays a reinforcing role.

XJY Silicones

At present, the XJY SILICONES brand of Jiangxi New Jiayi New Materials Co., Ltd has three major silicone product lines: Hydrosiloxane, MQ Resin, and Silicone Pressure-Sensitive Adhesive. Silicone MQ resin is one of the silicone resins, it has a unique structure and excellent performance, mainly used as silicone pressure-sensitive adhesive surface treatment agent and viscosities, silicone rubber reinforcing filler, silicone defoaming agent, anti-sticking agent, high-temperature resistant coating, mold release agent, etc.

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry. We are manufacturing and customizing MQ Resin in many fields, our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.

![]()