Polyurethane for shoe soles is a microporous elastomer between rubber and plastic. It is a kind of microporous elastic structure with open holes. The diameter of foam cell is 0.01 ~ 0.1 mm, the density of free foaming is 0.25 ~ 0.35, (forming density is 0.3 ~ 1), and it usually has 1 ~ 2mm self-skinning, which has superior resilience and great energy absorption capacity. Therefore, its density and hardness can be adjusted in a wide range according to the requirements of use, and it can be made into a two-color (dual-density) double-layer shoe sole. The lower sole is a micro-foamed high wear-resistant working surface, and the inner sole is a comfortable elastic foam.

The silicone mold release method is simple, which can be used to produce both sole and Lianbang shoes. Production process: the raw materials of component A and component B are completely melted in the preheating oven of raw materials, C material (catalyst) and color paste are added into A material as required, and they are respectively added to the original liquid tank of the sole forming machine, and the rotation speed of metering pumps of two components (A1, A2 and b) are respectively adjusted according to the formula requirements and pouring amount. The two groups of raw liquids are mixed evenly in the mixing device by high-speed stirring and a chemical reaction occurs. The mixture is poured into the shoe mold (the pouring time set by the computer program controller is adjusted by the size of the shoe mold cavity). After being capped, the shoe mold is sent to the drying channel of the circular production line for heating and curing (the production of a two-color sole must be solidified and then poured for the second time). The cured PU sole is demolded, trimmed, sorted, and inspected to be the finished product. The shoe mold is sprayed with the silicone mold release agent and then sent to pouring. The speed of the production line can be adjusted according to the aging requirements of the stock solution in the whole production cycle.

The following is the demolding process:

![]()

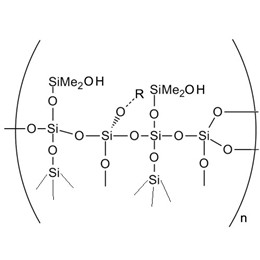

Polyurethane soles are divided into ordinary PU soles (outsoles, midsoles) and Lianbang shoes. For ordinary PU soles, water-based release agents are now the mainstay. The common products on the market are Kentian and some domestic brands. For Lianbang shoes, the most common ones on the market are oil-based, and the common products are Bluestar and some domestic brands. Silicone mold release agent added with MQ resin is a semi-permanent mold release agent with a wide range of uses. It has excellent mold coverage, good thermal stability, non-carbonization, less piles on the mold, no residue on the mold, and the surface of the molded part does not need excessive cleaning so that it can play a demolding role in multiple molding cycles after one use. Water-based release agent after adding MQ resin, silicone emulsion with a content of about 60%. It can be directly diluted and used, but it needs to be prepared for immediate use. There is no need to clean the mold before coating because it has excellent wetting and spreading performance and a good demolding effect.

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

We manufacture and customize silicone MQ resin in silicone mold release agents, our manufacturing, R&D, and sales services obtained the ISO9001 certificate.

XJY-8205 MQ resin series can be applied to the Silicone Mold Release.

![]()