Silicone oil can be used as the fabric softener, lubricant, waterproofing agent, finishing agent and so on in the textile and garment industry. In order to meet the high-end needs of textiles, chemical product manufacturers are also constantly developing silicone oils that can be used in various functional additives such as waterproofing agents, flame retardants, antistatic agents, and fixing agents. In addition, in order to improve the performance of the fabric, there are silicone products that can be used in dyeing, silicone oil for cotton with a cool feeling, silicone products that can improve the hand-feel of the fabric, and can give the fabric an excellent deepening effect and storage stability, not affect the colorfastness, good hand feeling silicone deepening agent, etc. In addition to being used as additives in textiles to achieve the functionalization of textiles, silicone products will also be applied to other areas in textiles, such as the combination of silicone and polyurethane to form textile silicone coatings; the polymerization of silicone and acrylic acid to form textile printing; the combination of silicon and organic fluorine forms a waterproof silicone coating on the fabric.

Fabric silicone coatings technology can no longer be simply regarded as a fabric finishing technology. The silicone coating on fabric will make the fabric have special properties and functions that the finishing technology cannot achieve. Silicone fabric coating products have developed rapidly in recent years, and there have been new breakthroughs in apparel fabrics or in decorative and industrial textiles. In the future, silicone coating technology will make great achievements in the development of functional fabrics.

The best silicone coatings can increase the tear resistance of the fabric by more than 50%. The silicone elastomer coating has high flexibility and low elastic modulus, allowing yarns to migrate and form yarn bundles when the fabric tears. The tearing strength of general fabrics is always lower than the tensile strength. However, when the silicone coating is applied, the yarn can significantly improve the tear resistance.

The silicone coatings can produce a water repellent effect so that the textile will not absorb too much water, so as to prevent the wetting effect from increasing the weight. The silicone coating layer can filter out most of the harmful ultraviolet rays in the sun, has long-term weather resistance, can withstand temperatures from -50°C to +200°C for a long time, and feels soft. Silicone coatings are now used in airbag fabrics, hot air balloons, paragliders, spinnakers, tents, sleeping bags, and many high-performance sports and leisure fabrics.

Among these many characteristics, the anti-slip function of silicone coatings is widely used in underwear, sportswear and smart wear, as well as in medical applications that require elastic and tightly bonded fabrics to the skin. According to their use, these products must have appropriate elongation or elasticity and softness. When applied to high-stretch fabrics, elastic bands, lace and narrow fabric belts, they must have satisfactory non-slip properties. These non-slip coatings are also used in clothing accessories, such as smart bracelet straps, socks, wearable technology and sports equipment.

With their unique functional characteristics, silicone coatings can greatly enhance the performance of modern fabrics. It even involves transportation, agriculture, construction, aerospace and other industrial fields.

XJY Silicones

- XJY-701 Polymethylhydrosiloxane: applied to coating leveling agent and fabric finishing agent; water repellents and softeners for synthetic fibers.

| Product Name | Hydrogen content(%) | Viscosity (25℃,mm2/s) | Reflective Index(n25d) | Density (25℃,g/cm3) | Volatile (105℃/3h) |

| XJY-701 Polymethylhydrosiloxane | 1.58-1.62% | 15-30 | 1.390-1.410 | 0.995-1.015 | ≤1% |

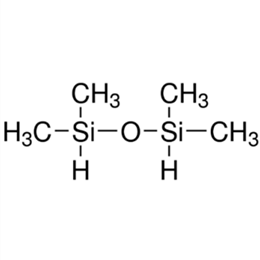

- XJY-706 1,1,3,3-TETRAMETHYLDISILOXANE (TMDSO): used as the waterproof agent for textiles, paper, and leather.

| Brand | XJY-706 |

| Product Name | 1,1,3,3-Tetramethyldisiloxane / TMDSO |

| Molecular weight | 134.32 |

| Flash point | -12℃ |

| Content (%, ≥) | ≥99% or ≥99.5% or ≥99.7% |

| Boiling point | 69~71℃ (Easy to volatilize) |

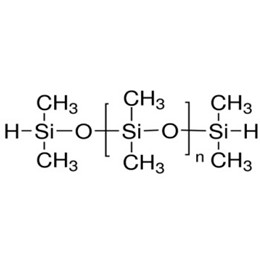

- XJY-707 Hydride Terminated Polydimethylsiloxane: as a waterproofing agent and softener for natural and synthetic fabrics.

| Brand | XJY-707-30 | XJY-707-015 | XJY-707-030 | XJY-707-050 | XJY-707-075 | ||||

| Products Name | Hydride Terminated Polydimethylsiloxane | ||||||||

| Appearance | Colorless clear liquid | ||||||||

| Content of Hydrogen (%) | 0.27-0.30% | 0.015-0.017% | 0.030-0.034% | 0.048-0.052% | 0.073-0.078% | ||||

| Viscosity (25℃,mm2/s) | 4-7 | 250-350 | 100-150 | 50-80 | 30-50 | ||||

| Volatile matter (105℃/3h) | / | ≤3% | ≤3% | ≤3% | ≤3% | ||||

| Hydride Terminated Polydimethylsiloxane can be customized according to customers’ requests. | |||||||||

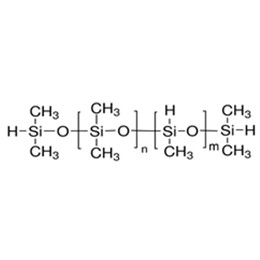

- XJY-711 Hydrogen Terminated Methylhydrogensiloxane Dimethylsiloxane Copolymer: as a fabric, construction, and other waterproofing agents and finishing agents.

| Brand | XJY-711 | ||

| Appearance | Clear Liquid | ||

| Content of Hydrogen(%) | 0.45±0.02 | 0.75±0.05 | 1.00±0.02 |

| Viscosity(25℃,mm2/s) | 10-40 | 40-60 | 40-60 |

| Volatile matter (% ,105℃/3h) | ≤3 | ||

| Refractivity( | 1.390~1.410 | ||

| Density (25℃,g/cm3) | 0.98~1.10 | ||

Choosing the right product mainly depends on the customer's manufacturing process, operating requirements, curing conditions, equipment, and material performance requirements.

XJY Silicones as one of the leading silicone manufacturers is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry. Our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.