Silicones have a wide range of applications in a number of industries, including medical, food, and electronics, due to their unique physical and chemical properties. However, the high viscosity of silicone materials makes mold release a challenge in the production process. The use of silicone mold release agents can effectively solve this problem and ensure the perfect molding of products.

In this article, we will introduce the selection of silicone mold release agents and the correct use of the key points.

- What is a silicone mold release agent?

- How to choose a silicone mold release agent?

- Specific application scheme

- XJY-Silicone mold release

- How do silicone mold release agents perform better?

1. What is a silicone mold release agent?

The main role of a silicone mold release agent is to form a layer of smooth isolation film between silicone and mold, and reduce the adhesion of silicone and mold, so as to achieve easy mold release. This not only improves production efficiency but also helps to maintain the integrity and fineness of silicone products.

2. How to choose a silicone mold release agent?

When selecting a silicone mold release agent, the following factors should be considered:

(1) Release effect: Make sure the release agent can effectively prevent silicone from sticking to the mold and provide good release performance.

(2) Chemical stability: Choose a release agent that does not react easily with silicone to avoid affecting the performance of the product.

(3) Durability: Select the release agent with a long service life and high-cost performance.

(4) Safety: To ensure that the release agent is non-toxic, harmless, and safe for the operator and the environment.

3. Specific application scheme

When using a silicone mold release agent, it should be operated according to the following steps:

(1) Mold cleaning: Make sure the surface of the mold is clean and free of oil and dirt to improve the adhesion of the release agent.

(2) Even application: Apply the release agent evenly to the mold surface, either with a sprayer or a brush.

(3) Drying: Depending on the type of release agent, you may need to wait for some time for it to dry to form a barrier film.

(4) Pouring Silicone: After forming the isolation film on the surface of the mold, the silicone will be poured and molded.

Precautions

(1) Read the product manual carefully before use to understand the use and precautions of the mold release agent.

(2) Avoid excessive use of mold release agents, so as not to affect the adhesive properties of silicone products.

(3) The packaging and residue of the mold release agent should be properly disposed of after use to prevent environmental pollution.

(4) The correct selection and use of silicone mold release agents is important for improving the production efficiency and quality of silicone products. Through the rational use of silicone mold release agents, can effectively improve production efficiency, reduce production costs, and ensure the perfect molding of silicone products.

4. XJY-Silicone mold release

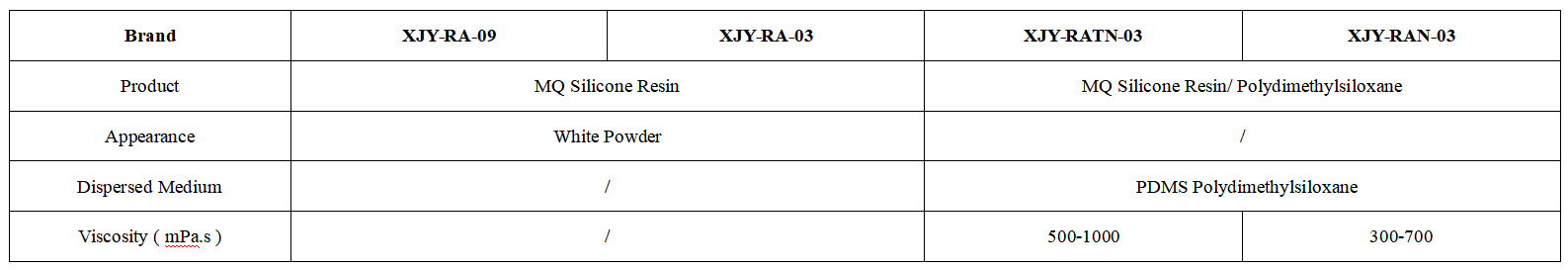

XJY-RAN series mold release agent is a semi-permanent special mold release agent for a wide range of applications.

XJY-RA/XJY-RAN MQ Silicone Resin is a polymerization of tetrafunctional silicon (Q) and monofunctional methyl silicon (M) in the field of silicone high-temperature, semi-permanent and permanent mold release agents. Silicone mold release agents are specially formulated to be resistant to high and low temperatures, have low surface tension, and are non-corrosive to metals. Adding silicone resin (5-15%) can significantly improve the strength of the silicone oil film, in the field of high-temperature casting and other areas of good application.

4.1 Scope of application

It is widely used as a mold release agent, especially for metal molds.

- Polyurethane molded parts: especially polyester type, polyurethane shoe soles.

- Miniature honeycomb automotive parts and furniture (integrity surfaces)

- Other automotive components: bumpers, shock pads, dashboards

- Durable release films in the manufacture of plastics, adhesives and elastomeric products

- Automotive polishes, additives in automotive care

4.2 Properties and Advantages

-Easy to use

-Can be diluted with solvents

-Forms a durable release film layer In most cases, a single application will provide release over multiple molding cycles

-Provides a heat-stable, non-carbonizing, non-greasy release film

-Good mold coverage (good wetting and spreading)

-Thermally stable

-100% silicone, solvent-free, high flash point

-Will not discolor molded parts

-Can be diluted with solvents

-Can be demolded in a variety of ways

-Odorless

-Excellent wetting properties

-Good color and gloss enhancement

4.3 Composition

XJY-RAN Contains polydimethylsiloxane and high molecular weight silicone resins

4.4 Dilution

For easier application and better control of the dosage on the mold surface, XJY-RAN should be diluted for use. For simple molds, a concentration of 5%-10% actives is appropriate. For complex molds, it may be necessary to dilute to a lower concentration of actives such as 1% in the same solvent.

Suitable solvents include most aliphatic hydrocarbons, aliphatic esters, aromatic hydrocarbons, chlorinated hydrocarbons, white solvents, isopropanol or volatile methylsiloxanes such as hexamethyldisiloxane.

In order to slow down evaporation and prevent premature solidification during spraying, we recommend (in part) the use of solvents with higher boiling points. Allow more time for drying before molding.

After dilution, XJY-RAN can be applied by spraying, brushing, or wiping.

4.5 Application points

( 1 ) Clean the mold surface before application. The best mold release characteristics are obtained when this product is applied as a very thin film. Excessive use should be avoided. Thick films have poorer mold release properties and may even result in sticking in multiple-part releases. Difficulty in release may also be caused by uneven dispersion or incomplete wetting of the surface. This can be corrected by wiping off the release agent until a dry thin layer is obtained.

( 2 ) For use on molds with porous surfaces, it is recommended that a more concentrated solution be used initially. Once the mold has been wetted with the release agent, a more dilute solution can be used.

4.6 Curing

Heat curing, although not essential, produces better release properties and improves the durability of the release film. It is recommended that the mold be heated at 90-200°C for 5-10 minutes to form a stable base film.

4.7 Fine tuning of frequency and concentration

Under actual conditions of use, the frequency of application and proper concentration should be determined by small-scale trial operations prior to actual operation to achieve optimum release performance. Generally, reapplication is required every two to ten molding operations.

After application, it is necessary to dry the mold surface until it is completely free of thinner (complete solvent removal).

4.8 Surface treatment of molded parts

In some cases, the silicon release film formed by XJY-RAN may also interfere with the painting and bonding of molded parts. If surface painting or bonding is required, the effect of the silicon release agent must be exhaustively tested before use.

As an automotive polish component, XJY-RAN fluid provides excellent gloss, water repellency, detergent resistance, and durability while maintaining excellent ease of use.

Application and erasing characteristics. This fluid is compatible with most water-in-oil and oil-in-water systems. This durability can be enhanced by the addition of a small amount of amine functional silicone or can be combined with a variety of organic waxes.

XJY-RAN fluid is used in automotive polishes in the range of 1-5 percent by weight. The optimum formulation for the actual use case should be decided by the end user.

5. How do silicone mold release agents perform better?

Silicone release agents offer several notable advantages. Firstly, their excellent release properties effectively prevent adhesion between the material and the mold, ensuring a smooth, defect-free surface for products, and making them suitable for molding processes involving plastics, rubber, metals, and silicone rubber. Secondly, silicone release agents exhibit outstanding high-temperature resistance, maintaining stability in high-temperature environments injection, which is ideal for high-temperature molding processes. Additionally, their strong chemical inertness prevents reactions with molds or products, extending the lifespan of molds. Silicone release agents are also environmentally friendly, being non-toxic and harmless, aligning with modern industry demands for green production.

XJY Silicones is one of the leading manufacturers of silicone MQ resins and VMQ silicones in China, with more than 30 years of R&D and manufacturing experience in the silicone industry, and more than 15 related patents and technical support. Our silicone raw material products can meet the needs of the mold release field and support the provision of diversified customized solutions.