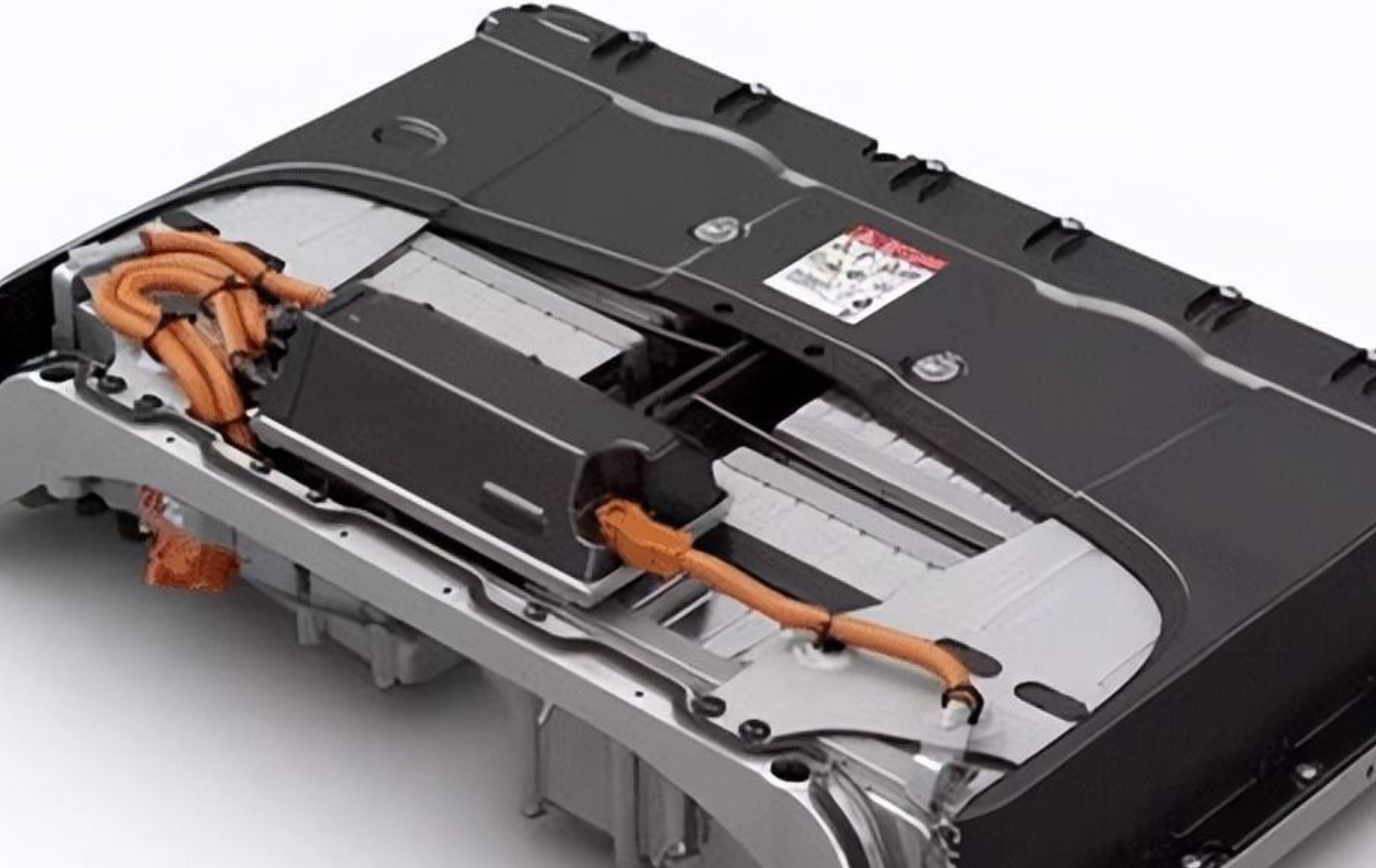

Silicones are used in a wide range of applications in the automotive industry, where their unique physicochemical properties make them important for battery safety, thermal management, durability, and insulation. How can silicones be used in new energy vehicles?

In the battery system, silicone thermally conductive potting compound is used for thermally conductive bonding between cells and sealing protection of battery packs to ensure battery safety and efficient heat dissipation. In the field of electronic control, thermally conductive silicone grease and silicone three-proof paint can be used for the thermal management of IGBT modules and the protection of circuit boards respectively. In the electric drive area, the application of silicone materials focuses on the thermal conductive potting of motors and converters, which is used to improve thermal management efficiency. In the body, waterproof sealing of intelligent network systems and lights relies on silicone potting compound and sealant, while silicone leather and coating enhance the durability and comfort of the interior. For the chassis, silicone rubber is mainly used in tire additives and shock absorber lugs to enhance vehicle stability and comfort.

There are five aspects to introducing silicone in new energy vehicles:

- What are the properties of silicone?

- Why use silicone in new energy trams?

- How is the market for silicone in new energy vehicles?

- What are the applications of silicone?

- How can new energy vehicles perform better?

1. What are the properties of silicone?

Silicone is a class of materials centered on silicon atoms with organic groups and oxygen atoms connected around them. Their main chain consists of stable silicon-oxygen bonds (Si-O), a structure that gives silicones their extremely high thermal stability. It is like a strong bridge, even in harsh high or low temperatures, can steadily connect the two sides of the river, to ensure the integrity of the structure.

2. Why use silicone in new energy trams?

(1) High and low temperature resistance

In new energy vehicles, batteries are the core of providing power. However, batteries are afraid of both cold and heat, silicone materials can effectively dissipate heat for battery packs and cores to improve the battery operating temperature. At the same time, high-end silicone materials in the battery pack can form a heat shield around the battery core, when the environment is too cold or too hot, the battery can still maintain efficient operation. For example, in cold environments, scientists have designed a kind of silicone material like “warm clothes”, which can form a heat shield around the battery pack to maintain the temperature of the battery. In hot environments, this material can be like a “cool umbrella” to help the battery heat dissipation, to prevent damage caused by overheating.

(2) Vibration and moisture resistance

In addition to silicone temperature control of the battery pack, new energy vehicles in daily use will have to face vibration, moisture, and other challenges. When driving a car on a bumpy road, the components in the battery may be damaged due to vibration. The durable silicone materials are particularly important. They act as a kind of “cushioning air mattress,” absorbing and minimizing the impact of vibrations on the battery and protecting the internal structure from damage. At the same time, silicone materials can also resist the erosion of moisture and other solvents, preventing harmful chemical reactions within the battery and thereby extending its service life.

(3) Flame retardant

Safety is the most important issue not to be ignored in new energy vehicles. Battery short-circuit may cause a fire, which no one wants to see. The insulating properties of silicone materials are particularly critical here. It can be used as a “safety barrier” to isolate key electronic devices in the battery, preventing electrical surges and the risk of battery fire. This is like installing a “fire door” inside the battery, once the danger occurs, it can block the spread of fire to protect the safety of the battery.

3. How is the market for silicone in new energy vehicles?

New energy vehicles in the amount of silicone materials compared to fuel vehicles about 3-4 times the growth of new energy vehicles as much as 20kg of silicone glue, about 7 times the amount of ordinary commercial vehicles. With the increasing global demand for higher-performance electronic equipment and the continuous development of digitalization, high-performance computing, automotive electronics, and other areas of silicone demand will continue to expand. In 2023 automotive silicone market size of about 11.3 billion yuan, by 2030 is expected to reach 20.2 billion yuan.

The environmental characteristics of silicone materials are also in line with the pursuit of environmental protection and sustainable development of the new energy automotive industry. The amount of silicone materials has accounted for 1% of the weight of the entire vehicle, showing its importance in new energy vehicles.

4. What are the applications of silicone?

In the field of new energy triboelectricity, silicone materials play an important role in the safety and protection of new energy vehicles by virtue of their excellent reliability and stability and are used in battery pack shells, powertrains, electronic control units, connectors, and other components to meet the safety, reliability and other performance requirements of the triboelectric assembly of new energy vehicles.

(1) Sealing/Bonding materials

In order to ensure the safety of power batteries, major OEMs have put forward comprehensive and strict safety standards and testing requirements for power batteries, i.e., through the airtightness test to achieve the full life cycle IP67 standards. Silicone materials with excellent waterproof performance can play a good role in waterproofing and moistureproofing of the battery pack, electronic control, gasket, and other components, helping to realize the sealing of the battery pack and protecting the internal components from dust, rain, and other erosion. In addition, in addition to meeting a certain level of protection, silicone materials are easy to use and can realize automated production to shorten the production cycle.

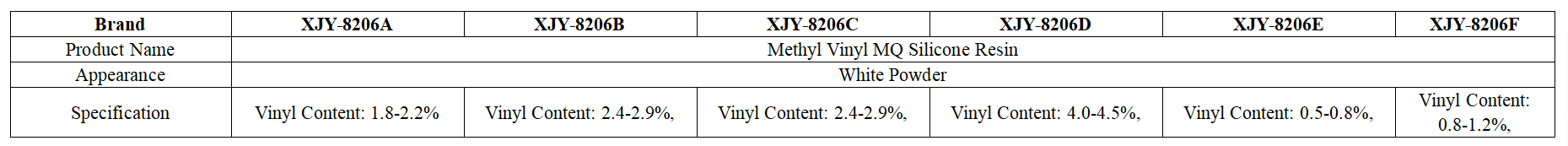

XJY-8206 Powder series methyl vinyl MQ silicone resin can be used to manufacture high transparent and high hardness VMQ silicone rubber, rtv silicone, and other LSR.

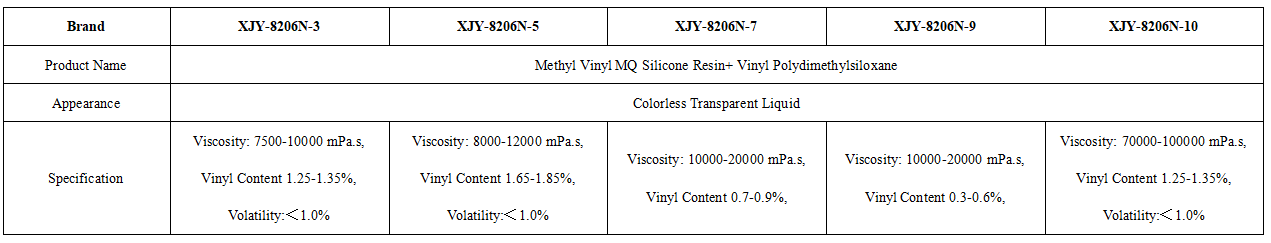

XJY-8206N Solution series methyl vinyl MQ silicone resin + vinyl polydimethylsiloxane can be used to make a two-component sealant.

(2) Three-proof materials

Under humid conditions, the battery management system (BMS) will slowly undergo electrochemical corrosion of the circuit board if no protective measures are taken, which will greatly affect the safe and reliable operation of the vehicle. Silicone three-proof paint material has good water repellency, can maintain its physical properties and electrical properties in a wide range of working environments, but also can resist ozone and ultraviolet degradation, and has good chemical stability. Especially in extremely harsh working environments, it is very useful for protecting circuits and maintaining a low-stress environment for components and circuits. In addition, the silicone three-proof material can be cured at room temperature or heated to accelerate curing, suitable for different process requirements, most of them contain a UV indicator, which can make the three-proof paint products visible under UV light, which is helpful for production inspection.

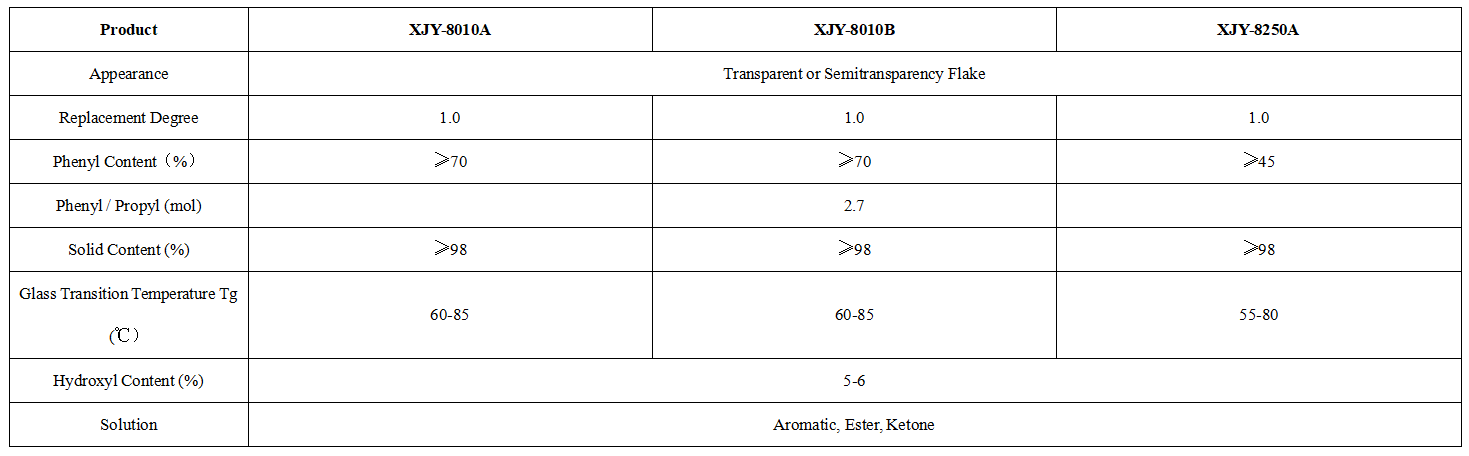

XJY-8010A/B/XJY-83350 Flake Silicone Resin

It can be used in high-temperature-resistant powder coatings and liquid coatings. The main feature of organosilicon resin is its excellent heat-resistant property, which hardly decomposes at 200℃ or even higher temperatures, and can be used to prepare various kinds of heat-resistant coatings with high reflection and heat-resistant insulation grades up to H class. Silicone's high solid resin has excellent radiation resistance and can be used to manufacture high-temperature powder and liquid coatings. Silicone resins have excellent resistance to radiation and proton oxygen attack. Silicone resins have excellent UV resistance and good adhesion. Silicone resins also have excellent resistance to weathering, ozone, arcing, hydrophobic moisture, salt spray, and mold. It can be used for existing roofs, kitchenware, etc.

(3) Potting materials

Silicone potting adhesive can provide protection for electrical/electronic devices and components in high humidity, extreme temperatures, thermal cycling stress, mechanical shock and vibration, mold, dirt, fluid leaks, and other harsh conditions, and can reduce the stress caused by vibration, mechanical shock, and thermal cycling. Silicone potting compound application in the thermal management of power battery has a good compensation and waterproof seal effect and, at the same time can alleviate the automobile operation in the event of impact, hard objects piercing, power battery pack charging and discharging time is short, overcharging and other insecurity, improve the stability of the power battery pack, and further enhance the overall safety of new energy vehicles.

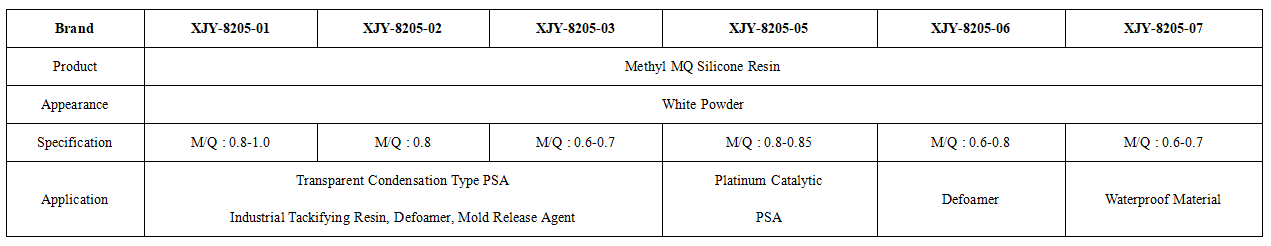

XJY-8205 Methyl MQ Silicone Resin

It is a solid powder resin, which can be used as a reinforcing material for liquid silicone rubber. Adding MQ resin to the potting compound can enhance the temperature change performance of the potting compound and prolong the service life of the potting compound.

5. How can new energy vehicles perform better?

In recent years, with the automotive industry to new energy, electrification direction of transformation and upgrading, silicone materials innovation and application of the focus from the traditional sealing, lubrication, insulation, and other basic functions, to new energy, intelligence, and other emerging areas of the transfer. In the future, with the accelerated electrification and intelligentization of the automotive industry, innovation in the field of application of silicone materials will continue. It is expected that power battery systems, intelligent sensors, lightweight materials, and other aspects of more high-value R & D results will continue to emerge, while the enhancement of environmental protection requirements will also promote the production of more silicone green innovation application results. How to improve the competitiveness of your products?

XJY Silicones is one of the leading silicone MQ resin and VMQ silicone manufacturers in China, with more than 30 years of R&D and manufacturing experience in the silicone industry as well as more than 15 related patents and technical support. Our silicone raw material products can meet the needs of automotive electronics and support the provision of diversified customized solutions.