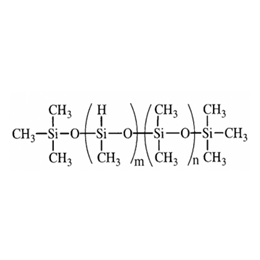

Silicone sealants are mostly synthetic silicone adhesives, the main body of which is polymer, and their properties can be divided into three categories: ontological properties, process properties and use properties (product performance). The nature of use mainly refers to the comprehensive performance of the sealant in the process of forming the glue joint to the formation of the glue joint, the performance depends on the functional requirements of the building joints for the sealant.

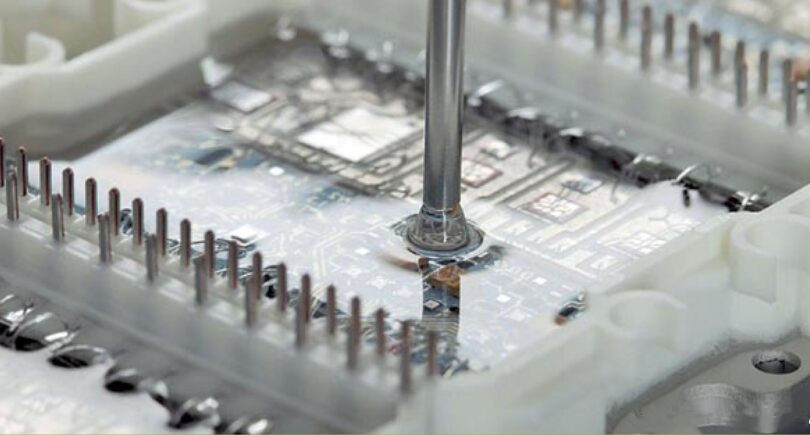

Whether for the construction jobs envelope or building interior decoration, whether window structure or other forms of the envelope and decorative structure, they can be seen as a unit composition, then between each unit will produce joints, and dut to silicone sealant has highly resistant to extreme temperatures and moisture, the vast majority of the need for building sealants to seal the filling. The rational design of building caulking cracks, the understanding of building silicone caulk and sealant, the rational selection of materials and the correct construction of building seals are essential to ensure the success of the whole process of sealing building joints. Besides, silicone sealant can be used in the cable insulation of electronic devices and various gaskets. This article collects and collates some of the common problems encountered in the actual use of acid silicone sealants and provides corresponding industrial purposes solutions for you.

![]()

1. Why will the acid adhesive bottles grow tall, deform and even have oil in the bottle after being stored for a period of time?

There are two reasons for this problem, i.e. it is related to both the glue paste and the bottle.

The first reason is the glue paste. Now the acid glue on the market, in addition to a few high-grade types of glue, other acid glues are to varying degrees to add a certain amount of filler to reduce costs, and the lower the grade of the glue, the more filler added, and filler will react with the glue bottle, so that the bottle will grow high, deformation and bottle oil; such as high-grade glue may make the bottle after 6 months to react, relatively low-grade glue may have a reaction after 6 months. The second reason is the bottle.

Secondly, the reason for the bottle. The quality of the material of the bottle itself is also the reason for the growth of the bottle, the raw material used in the bottle also has good and bad, the raw material used is good, and the trend of the bottle change is relatively slow. If the bottle is of good quality, it can be stored for 7-8 months without any reaction; on the contrary, if the bottle is of poor quality, it may be deformed in 2-3 months even if it is filled with good glue.

2. Why is the glue thicker or drier than the glue from the bottom of the bottle?

This is mainly caused during the packaging process. This is because it takes some time from loading the glue to pressing the lid, although the time is short, it also makes the glue paste have contact with the air. If the sealant cures a lot from the bottom, it is the bottom cover and bottle sealing is not tightly caused by the quality control of the packaging material.

3. Why is there flow interruption or small bubbles during the extrusion of acid glue?

This situation is mainly formed by the following two reasons.

One is caused by the low storage temperature: if the acid glue (especially the low-grade glue) is stored at a lower temperature a lot of bubbles will be formed. The reason may be that after the low-temperature storage, the liquid raw material forms more bubbles due to the change in the volume of cold shrinkage, so it is recommended that the storage temperature should not be lower than 0℃.

The second is the formation during the canning process: in normal canning, there are often a small number of small bubbles at the end of the branched glue, which is difficult to avoid in the current way of operation and does not have a substantial impact on the use: if there are more bubbles or breakage (large bubbles), it is caused by improper operation, which must be improved and should be avoided at all costs. However, there is a probability of this occurring, and if it is rare or occasional, it should be regarded as a coincidence. Large bubbles should be avoided as much as possible during operation.

4. Why does the acid glue wrinkle on the surface after curing?

This is mainly caused when the adhesive layer is too thin while sizing the surfaces of the two substrates. Due to the different thermal expansion and contraction rates of different materials, resulting in a large temperature difference, the glue that is not fully cured will deform and wrinkle.

Solution: Thicken the adhesive layer. Generally, the thickness of the adhesive layer is about 1mm during construction. It is recommended to increase the thickness to (1.5-2)mm.

5. Why do some acid glues change the color of aluminum after curing?

When the acid glue is cured, it will release acetic acid, which is corrosive to metal materials. The reason why it can be used on aluminum is that the surface of the aluminum is coated with an oxide film or coating, which can protect it. So generally speaking, discoloration of aluminum is not a problem with glue. It should be more about construction operations and the quality of aluminum itself. It mainly means that the coating layer of the coated aluminum material is not qualified, such as poor adhesion, too thin film layer, etc., which will affect the discoloration after sizing, and improper construction will also cause discoloration. If the aluminum material is placed in a poorly ventilated environment after sizing, the acetic acid released by the curing of the glass glue cannot be dissipated in time, and the local concentration is too high, which will corrode the aluminum material for a long time and cause discoloration.

6. Why does the adhesive strip turn white or yellow after curing?

Yellowing: In more cases, the yellowing of the adhesive strip is caused by the influence of other materials in contact with the glass adhesive. The most common is to put glass glue on some black rubber strips (inserted and sealed between the glass and the aluminum). Due to the poor quality of some glue strips, contact with glass glue makes it yellow, even imported glue is no exception. Generally, the rubber strip discolors the glass glue, which may be caused by the material used in the rubber strip. Specifically, the filler reacts with the acid glue to change the color of the transparent glue, and it is not excluded that the precipitation or volatilization substances are added to the rubber strip to contaminate the glass glue strip.

Whitening: The whitening of the glass glue is mainly due to too much filler added in the sealant. It often occurs in some projects where the glue layer is too thin, so it is recommended to increase the thickness of the glass glue (1.5-3mm) when gluing to avoid similar situations.

7. Why do some sticky paper and some non-stick paper appear when the glass glue is applied to the paper?

Glass glue is not used to stick paper, so sticky paper and non-stick paper will not affect the actual use, but sticky or non-stick paper is related to some characteristics of paper and glass glue. First of all, the material and texture of the paper have a great impact on the sticky paper. If the paper fibers are loose, the glass glue will easily wet the paper and stick to the paper. Secondly, the glass glue also has an impact. The preliminary analysis has a certain relationship with the curing speed. For example, low-grade glue is slow to cure and easy to stick to the paper.

8. Why does the glue strip of the cured transparent acid glue turn white after being stretched?

Because solid fillers are added to many acid gums to increase strength, the solid fillers appear white after stretching, so they look white. This situation mostly occurs in domestic adhesives. Due to cost constraints, the solid fillers used are different from imported adhesives, but they have no effect on the performance and actual use of glass adhesives.

9. Why is the deep curing of glass glue slow?

Deep curing has a lot to do with the use environment. Generally, glass glue cures slowly in an environment with low temperature and high humidity. In addition, curing is slow in poorly ventilated environments. Then there are different grades of glass glue, the curing speed is quite different, especially the domestic glue, the curing speed of the low-grade glue is obviously different than that of the high-grade glue, and the difference is especially obvious when the ambient temperature is low. Therefore, it is recommended that domestic low-grade adhesives should not be used near the specified lower limit temperature (5℃).

10. Why does the glass glue shrink after curing?

All sealants shrink after curing, but high-grade and low-grade glues have very different shrinkage rates. For example, high-grade glue shrinks only 5% after curing, while low-grade glue may shrink by 30% or more. This is because the low-grade glue is added with filler, and the filler will slowly volatilize in the air, so the more filler, the greater the shrinkage rate.

11. Why is there a small amount of oil separation at the mouth of the bottle?

This is a normal phenomenon of long-term storage, generally stored for more than 3 months, but the probability of this situation is not very high in practice, because the glass glue oil separation occurs only in the case of a long period of resting, and the branch glue is often in motion due to sales, such as transportation, loading, and unloading, finishing the warehouse, etc., which is equivalent to constant mixing, so more time will not appear the phenomenon of stratification. The reason for a small amount of oil separation is that the product is composed of liquid and solid raw materials together, due to the different specific gravity of each, the phenomenon of sinking will occur only when it is left for a long time, but because this process is very slow, so it does not affect the use and product performance, the imported glue also has this phenomenon.

12. Is the sour smell of vat glue bigger than that of imported acid glue?

The difference is mainly in the low-grade glue because the basic material of domestic low-grade glue is limited by the cost, which leads to a shorter storage period. In order to improve the storage period, we need to add a variety of additives, the smell is big, but the release is mainly acetic acid, which is not harmful to people.

13. Why do some glass adhesives dry too fast without trimming time?

This is related to the construction temperature and operation. It is recommended to avoid the high temperature when construction, increase the number of trimming, if the original play 2 meters long school seam before trimming, can be changed to play 1-meter long glue seam after the trimming, so as to reduce the adverse effects caused by the table drying too fast.

14. Why is there oil seepage on the paper when the adhesive strip is hit?

First of all, different paper is affected by its texture, material and other factors, such as the paper fiber is looser, so the filler added in the low-grade glue will seep into the pores and produce the phenomenon of oil seepage; but after experimental observation, this situation does not occur in actual use, that is, in aluminum and glass, there will be no oil seepage, and it will not affect the bonding, strength and other properties.

15. Why is the level of high adhesive (including imported adhesive) more non-stick aluminum?

Because its curing speed is too fast, resulting in the glue paste does not completely infiltrate the surface of aluminum, that is, it can not penetrate into the surface of the substrate microporous and is not sticky. This phenomenon does not affect the normal use of glass adhesive. High-grade glass adhesive mainly two, one is a large glass curtain wall or point curtain wall, glass adhesive used here only contact with glass, not with other materials, so not sticky aluminum does not matter; the second is used for glass aluminum alloy doors and windows caulking, glass adhesive filled in the joints between the glass and aluminum alloy, although the glass adhesive and the aluminum alloy bonding force is not good, because of good bonding to the glass, will not fall off, as a caulking seal used and Do not bear the load (i.e. do not force), so as long as it can adhere to the aluminum alloy, it can play a sealing role.

16. Is there crystallization in the acid adhesive?

This phenomenon only occasionally occurs, mainly because the storage temperature is too low, because many additives added to the acid glue system have a high freezing point, although the additives have been integrated into the slurry, in a long time at low temperature will still turn into crystals and precipitation, so the storage temperature to avoid too low.

17. Why do acid silicone sealants turn red?

This phenomenon only occasionally occurs, mainly due to the instability of raw materials, so we must control the inspection of raw materials.

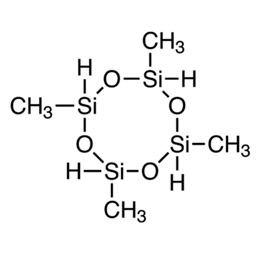

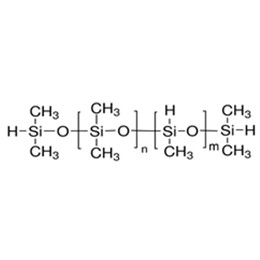

XJY Silicones - First choice raw material supplier of silicone sealants

XJY Silicones, one of China's leading Silicone MQ resin and VMQ silicones manufacturers, has 30+ years of R&D and manufacturing experience and 15+ related patents and technical assistance in the silicone industry. XJY Silicones is delivering tailored silicone sealant solutions, we can provide hydrogen-containing silicone oil and vinyl silicone oil or VMQ silicone resin according to your applications requiring specifications.