Because the main chain of silicone softeners is -Si-O-, which is longer than -CO-, the molecular chain is softer and has excellent lubricating and softening properties. It has a wide range of applications and can be used in textile finishing. Its development process has gone through the following three stages.

![]()

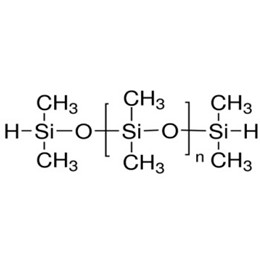

As early as 1940, the United States published a patent report that treated fibers with dimethyldichlorosilane had a waterproof effect. In 1945, an American company soaked the fiber in an alkaline aqueous solution with sodium methylsiliconate, and heated it to make the fiber have a good waterproof effect. In the early 1950s, an American company discovered that the Si-H-containing hydrogen-containing polysiloxane treated fabrics had a good waterproof effect and good air permeability, but the hand feeling was poor and the silicone film was hard and brittle and easy to fall off. Used together with polydimethylsiloxane (PDMS), not only has a good waterproof effect, but also has a soft hand feeling. Since then, despite the rapid development of silicone products in Europe, the United States, Japan, and other countries in the world, there are many products, but they are basically mechanical mixtures of dimethyl silicone oil, collectively referred to as silicone oil type products, that is, the first generation of silicone fabric softening Agent, dimethylpolysiloxane (DMPS) is the representative of the first generation of silicone softener.

![]()

![]()

Polysiloxanes with a high molecular weight with terminal hydroxyl groups were earlier considered to be ideal fabric silicone softeners. For ease of use, they are generally made into emulsions. In 1959, the American company first applied for the patent for the direct production of hydroxy silicone oil by emulsion polymerization. It was not until 1969 that the company published a research report on siloxane emulsion polymerization. In 1972, published a report on the application of hydroxy-terminated polysiloxane emulsion to fabric finishing by emulsion polymerization. In 1976, the company announced the successful development of hydroxy silicone oil emulsion by emulsion polymerization and its application in fabric softening and finishing. The hydroxy silicone oil emulsion is different from the mechanically mixed emulsion. It is a cationic emulsion with good stability and strong adaptability, which can improve the washing fastness of fabrics, thus making a big step towards permanent soft finishing. Subsequently, various types of hydroxy silicone oil emulsions used in fabric finishing have been developed, which belong to the second generation of silicone fabric silicone softeners.

![]()

![]()

Because the second-generation silicone softener has a single function and is easy to demulsify and bleach oil during use, silicone workers have competed to develop the third-generation silicone softener, that is, modified silicone softener. This kind of product is through the introduction of amino, epoxy, polyether, hydroxyl, and other active groups on the side chain of siloxane, which greatly improves the washing resistance, shrink resistance, hydrophilicity, etc. of the fabric, and rely on Different groups give the fabric different styles. At present, people's research on silicone softeners is mainly focused on third-generation silicone products.

![]()

![]()

![]()

Among the third-generation silicone softeners, the first-generation softeners are generally mixed with the second- and third-generation softeners or other types of softeners and additives because they are not washable. The second-generation softeners are the most mature and widely used category, currently used both at home and abroad. Some of the third-generation products are mature, but some are still under research, improvement, and development.

![]()

XJY Silicones

XJY Silicones is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

We are manufacturing and customizing XJY-701 (Polymethylhydrosiloxane(PMHS)) and XJY-707(Hydride Terminated Polydimethylsiloxane(HPDMS)) for silicone softener, our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.

![]()