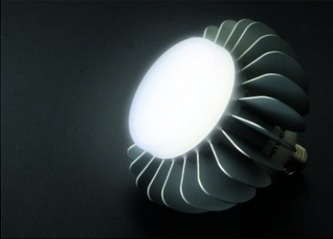

As early as the end of the twentieth century, the concept of light diffuser material is proposed. Light diffuser material refers to a material that can not only pass light but also effectively scatter light. It can convert a pointolite into a line source or a line source into a area light, and can be used as a area light material in the led light diffuser sheet, electroluminescent panels, guides light plates, backlight devices liquid crystal displays and other equipment.

Property

The led light diffuser sheet is obtained by uniformly dispersing the light diffusing agent in the LED board. It has excellent light diffusion, light transmittance, good UV stability, and is widely used in the LED industry. This is because the light diffusing agent in the light diffusing material is evenly distributed. The light passes through the material evenly without exposing the lamp beads to achieve the effect of optical diffusion.

Principle

The principle of light diffusion is: when light irradiates the surface of the led light diffuser sheet, because the refractive index of the PC resin and the light diffusing agent are different, the light is similar to mirror reflection on the surface of the light diffusing agent, and after multiple reflections, the light diffusion effect is achieved. At present, the led light diffuser sheet has attracted wide attention from scientists at home and abroad and has formed commercial applications. Some well-known companies have developed related products and have won a wider market.

Challenge

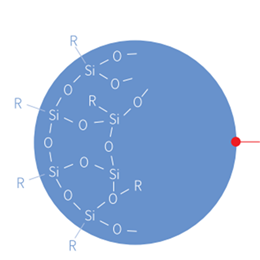

However, there are some problems with the led light diffuser sheet, The most significant is the yellowing phenomenon in the production process and the high material cost. This is directly related to the selected light diffusing agent (including the comprehensive combination of light diffusing agent and resin system and auxiliary system) and the mixing process used. If you choose Polymethylsilsesquioxane ( Spherical Silicone Resin Powder) as silicone light diffusing agent, you can achieve better results when the amount of addition is small, the cost is relatively low, but the process requirements are high, and the LED sheet is very easy to turn yellow if using a simple single-screw extruder which has the problem of dispersibility. In addition, make sure that the machine is cleaned, and run through the machine with water and transparent particles in turns. The led light diffuser sheet will turn yellow if any carelessly.

XJY Silicones can provide XJY-801 Polymethylsilsesquioxane(PMSQ) silicone resin as the light diffusing agent that can be applied in the silicone led light diffuser sheet.

It is believed that with the continuous advancement of led light diffuser sheet production technology, a new generation of light sources with higher comfort will be provided to people, which will not cause eye fatigue, glare, and other discomforts while ensuring brightness.

XJY Silicones

XJY Silicones as one of the leading silicone manufacturers is a new enterprise for silicone resin innovation and R&D, with more than 30 years of experience in the silicone industry.

We are manufacturing and customizing XJY-801 Polymethylsilsesquioxane(PMSQ) silicone resin in light diffuser material products, our manufacturing, R&D, and sales services had obtained the ISO9001 certificate.