According to the material classification, there are 5 or 6 types of protective film. Here we’d like to learn about the PET material protective film. There are many people who don’t know the function of PET protective film and are confused with other material protective films, so let me explain today.

- What is the PET protective film?

- What is the function of PET film?

- What is the chemical structure of PET protective film material?

- What are the applications of PET film?

- Reasons and solutions for adhesive transfer of PET protective film

- First choice supplier of silicone PSAs for PET film

What is the PET protective film?

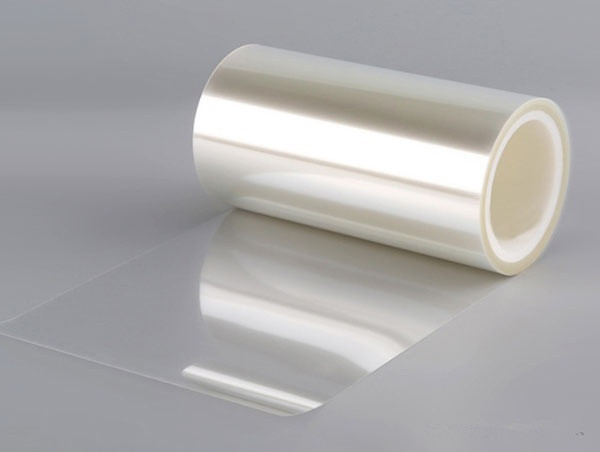

| PET protective film is a common protective film on the market. Three-layer PET protective film is often used for screen protection of mobile phones and tablet computers. The chemical name of pet protective film is polyester film. The physical properties are that the texture is relatively hard, high gloss and scratch-resistant, and it will not turn yellow and oily like PVC materials for a long time. |  |

The main feature of PET polyester films is that there will be no migration of electrostatic materials on the surface of the protective film, and it is non-toxic, tasteless biaxially oriented, and environmentally friendly, and the use effect is also good. Therefore, PET anti-static protective film is widely used in packaging materials, boards and displays in order to obtain the desired effect.

The protective film of the general PET material relies on electrostatic adsorption, which is easier to foam and fall off, but even if it falls off, it can be reused after washing it in clean water. The price of PET protective film is much more expensive than that of PVC. Using PET material protective film protective stickers, there are special protective stickers customized for hot-selling mobile phone models, which can be used directly without cutting.

What is the function of PET film?

1. Dustproof

Used for protection and not stick to dust, And covering so that dust cannot enter.

2. Anti-scratch

Used for screen and other items that are prone to scratches, avoid scratches during use and achieve the effect of protecting the screen panel.

Static electricity is generated in various ways, such as contact, friction, peeling, etc. The protective film is used to protect precision electronic components.

4. Brightening

Brightening film is an optical film with a uniform prism pattern formed on the surface of PET with very good transparency, using acrylic resin, to protect the screen and increase the light transmittance.

5. Breathable

Silicone rubber film has good selective breathability, and the permeability of nitrogen, oxygen, carbon dioxide and other gases at room temperature is 30 to 50 times higher than that of natural rubber.

The PET protective film is a kind of multifunctional protective film, which can be fully used in plastic, hardware, backlight, polarizer, IOT film, brightening film, diffusers and other fields. The role of PET protective film can be summarized as dustproof, anti-scratch, anti-static, light and breathable.

What is the chemical structure of PET protective film material?

PET is polyethylene terephthalate (PET), which is made up of terephthalic acid and ethylene glycol in a condensation polymerization reaction. The general PET protective film material has a surface hardening value between 3H and 4H depending on the origin, the better the surface hardening, the greater the resistance to wear and tear. Light transmittance is also the main property of PET protective film material, generally, light transmittance is above 90%, and high light transmittance not only has a good visual effect when we use related instruments but also has a good protective film effect on the eyes. Now, in the PET protective film market, Japanese materials are superior, Taiwan is second and Korea is third.

What are the applications of PET film?

Pet protective film has a wide range of applications and can be used for: metal products, coated metal product surfaces, plastic film, automotive applications, face shields, electronic insulation, sign product surfaces, profile product surfaces, food packaging, and other product surfaces.

Due to its dimensional stability, the protective film can be divided into plastic protective film, digital product protective film, car protective film, household protective film, food preservation protective film, etc. However, with the popularity of digital products such as mobile phones in China, protective film has gradually become a general term for screen protectors, and its functions in the field of screen protectors are also varied. The most basic requirement of screen protectors is high-definition scratch resistance.

Reasons and solutions for adhesive transfer of PET protective film

The sticky transfer phenomenon is collectively referred to as residual sticky displacement of a surface during uneven coating and transport.

The glue transfer problems:

1. Cohesive failure

The adhesion between the surface of the profile and the surface of the substrate, and the loss of gloss on the surface of the protective film coating

2. Damage to the sticky base

There is a lot of glue residue on the surface of the profile, and the glue surface of the protective film can see the base material

3. Transmission residue

A small amount of adhesive remains on the surface of the profile, and the protective film adhesive maintains a good gloss.

Cause analysis:

Quality problems in protective film production technology, substrate (PET) and raw material (bonding) lead to deterioration.

Solution

1. Improving technology and perfecting science and technology is quality assurance.

The process requirements for coating production include binder ratio, binder amount, binder uniformity, curing agent ratio, dispersion uniformity of curing agent in the binder, mechanical speed, temperature setting, drying effect, etc.

2. Improve the quality of the adhesive.

For example, the use of high gel fraction adhesives, the use of copolymerization or bonding techniques of long carbon chain acrylate monomers that increase the degree of cross-linking with the article; the addition of specific UV absorbers to optimize formulations and adhesive production to reduce UV aging process to improve the heat resistance and low-temperature resistance of the adhesive.

3. Improve the surface tension of aluminized PET film.

PET itself is a polar material, and there is a certain tension on both sides. The tension value gradually decays over time. The corona processor performs an online electro-activation treatment to improve the bonding force between the PET substrate and the adhesive.

4. Improve the cross-linking degree of the adhesive. Cohesion can be improved by improving the adhesive formulation, increasing the proportion of crosslinking agents, etc.

XJY--First choice supplier of silicone PSAs for PET film

| XJY Silicones, one of China's leading silicone pressure-sensitive adhesive manufacturers, has 30+ years of R&D and manufacturing experience and 15+ related patents in the silicone industry, also can customize the products according to your PET film requirements. |

SPSA is a colorless and transparent viscous liquid, which can be used for various adhesive tapes, has good physical and chemical properties: shear and tack properties, and has unique features of silicone such as aging resistance, high and low-temperature resistance, no residue after stripping for crepe paper, PET film and other adhesion tapes, has the good adhesive ability.